How to balance Taggant with Ink – 3

How to balance Taggant

(Marker Ink) with Ink

– Simple Laboratory Test-

– III –

(Marker Ink) with Ink

– Simple Laboratory Test-

– III –

(Written by : N. R. Jayaraman )

PARTICLE SIZE OF THE TAGGANT

The particle size of the pigment or the taggant is very important factor in determining the effective working and balancing of Ink- Taggant. The particle size is always expressed in terms of microns.

Like the pigments in inks, the particle size of Taggants too affect the print quality unless it blends well with the particles of the colored pigments present in the ink. So both the pigments and the particle size of the taggant powder plays an important role wherever they are put to use together.

The particle size is measured by simple manual rubbing on particle size measurement s lab which needs experience to handle or by automatic equipments such as dynamic light scattering (DLS) devices. Most of the ink pigments fall into the range of 50-200 nm (microns).

Manual Particle size rub Test slab with scale

When the particle sizes of the pigments are in the following range one can expect trouble free printing and free flow of ink on rollers and ink duct.

- General Wet offset inks < 5-6 microns

- General Dry offset inks < 5-6 microns

- Intaglio inks around 20-25 microns

- Flexographic inks <5-8 micron (slightly courser is acceptable –e.g. 15 micron can be run with a high release anilox but not totally problem free)

- Writing or liquid inks which is powder based. Since they are Solubilised dye–the particle size should be theoretically zero micron.

In view of the above, if the particle size of the Taggants are kept below 1- 2 micron, it will get blend well with ink to produce excellent result.

In my personal opinion the smaller the size of the particle, the better will be the tendency to blend well with the liquid ink , particles being lighter in weight. To determine the ideal particle required for working the following trials could be carried out.

Step one

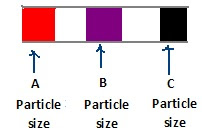

- Get two or three grades of Taggants in particle sizes say mean 5 micron, mean 3-4 micron and mean 2-3 micron and test the result in the same way to see which works better.

- Once you short list the grade then the set of samples can be taken up for actual machine trial as there will be 10- 15 % variation in performance between machine and lab trials which are manually operated . Such minor variations can be easily adjusted on machines.

Machine trial

Step Two

The machine trials could be taken at the beginning of the day when the rollers would have remained fresh or after the production is completed. But before taking machine trials the inking roller and ink duct must be well cleaned to observe sedimentation or clogging of the Taggant powder.

Since no machine make ready will be required and the ink will have to be simply poured from the container no special care may be necessary.

Maximum of three samples of liquid ink in three different colors – Violet, Red and Black could be used avoid mix up of the samples.

The above exercise will help in assessing:

- Whether ink agitator will be required to ensure perfect blending of Taggant with the ink or not.

- Whether the final consignment could be obtained in small size bottles of 100 or 200 ml which can be shaken well and poured manually in the ink duct or directly on the roller.

- Whether the Taggant has tendency to sediment if the ink duct solution is not constantly stirred .

- Whether the Taggant blend well with the liquid ink and flow freely from the ink duct due to the continuous rotating action of the ink roller which continuously rotates in the duct once the machine starts working.

- The strength of the solution (percentage of the Taggant) which needs to be supplied.

- Whether adding 10- 20 % thinner at frequent intervals in the ink duct continue to maintain desired result or whether fresh solution is only needed to be poured in the ink duct.

- Since there will be no vibrating rollers in the inking unit , while taking machine trials the three grades of solution could be poured in three parts with a gap of 1 inch minimum and prints taken so that in one run the performance of the three samples can be tested without wasting much time .

———–CONCLUDED———-

Recent Comments