Students Guide to Printing – 44

Guide to printing students

-Few objective Questions and answers-

186) Briefly explain the process of registering the images on paper for final printing.

- Jog the paper to be printed and pile the paper in the feed board along with few hundred sheets of make ready paper (lower priced sheets compared to the actual sheets to be printed). Generally the pile of paper is jogged well and stacked at the center of pile board.

- The feeder section consists of sheets separating suckers which pick up the top sheet of the paper from the pile and move them into the feed board. Once the sheet sucked is moved into the feed board, the next sheet is sucked and forwarded by which time the sheet in feed board gets aligned both in side and front lays to get ready to be gripped by the grippers. There are two types of suction feeders available on the machine. One is called sheet feeder and the other is called continuous feeder. In sheet fed machine the suckers are near the front edge of the paper while in continuous feeder, the suckers are on the back edge of the paper (Read the suction and continuous feeders separately).

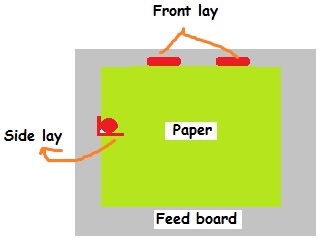

- In the feed board are few front lays and one side lay that guide the paper to retain specific margin on all the sheets moved into the feed board.

- At one point of time, from the feed board not more than one sheet will be held by the grippers and moved into the print unit.

- The press mechanism has been so designed that there will be no clash of sheets in reaching the front lay and till the top sheet above the next sheet below fully enter into the print station, the next sheet that follow below will not reach the front lay. The movement of sheets have been timed so.

- Each machine is fitted with double and triple sheet detector fitted between the pile board and feed board on the machines which is a special device that is adjusted to allow only one sheet to pass in the case of single sheet feeder or two to three sheets in case of continuous feeders to enter into the feed board.

- The registration of the sheets are done with the help of guide mechanism in the shape of metal tabs called front and side lays fitted on the feed board. They help the traveling sheets stay in perfect right angle before being gripped by the grippers of the print station to get prints on them.

- The front lay is set in such a manner that the specific amount of margin of the top edge of the sheet as pre-set is maintained on all the sheets that travel and similarly the side lay is also pre-set to maintain certain margin on the side edge of the sheet. Both the margins are necessary for perfect registration of the printed images on the sheets fed retaining the allowance for trimming the sheets to final size required.

- The front lay ensures that each sheet properly touch it before entering into the print station to ensure that the image gets printed exactly in the same position on the top side. Similarly the side lay ensures that each sheet touch its side wall before entering into the print station to ensure that the image exactly gets printed in the same position leaving specific margin on both sides. This aspect is very essential especially while printing multi-color jobs which are super imposed one upon the other.

- Thus the front and side lays are positioned in such a manner that as soon as the forwarded sheet from the pile board touches the front lays, immediately the side lays pulls them to touch its side wall to ensure that the sheet is fully aligned at right angle for registration of the images on paper. In the web fed machines no lays are fitted. However side guides are given to ensure that the reel of paper travelled maintain the side margin.

- Once the paper is well positioned in the side and front lays, the paper will be gripped by the cylinder grippers and moved into the print unit.

- The plate cylinder will be inked and inked image from it get transferred on to the paper when impression cylinder press the paper against the plate or intermediate blanket cylinder where the image had been already transferred.

- The plate which carry the print images will be fitted in a specific position on the cylinder in such a manner that the print will fall on all the sheets exactly in the same position required barring minor adjustments which may be required to move the image position on the sheets.

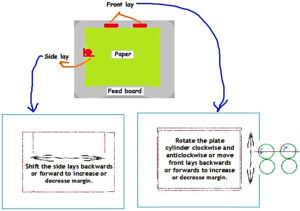

- The correct positioning of the plate on the cylinder will ensure actual margin required on both sides. However minor adjustment of margin required is made by revolving the plate cylinder in either direction – clockwise or anti clockwise and in either directions on the sides. Some times for adjusting the margin on the sides of the sheets, the web holding bar or side lays are moved in either direction to adjust the margin on the sheets.

- Fist only few make ready sheets are fed and side and front margins adjusted by moving the side lays, marginally moving the few of the front lays (when the adjustment for front margin is less than ± 0.5 mm) in feed board and by moving the plate cylinder clockwise or anticlockwise till the perfect placement of image on the sheet is completed as per layout.

- Once the image has been perfectly laid /positioned on the make ready sheet, few more make ready papers are printed and other adjustments made that includes colour, pressure, image quality etc to conclude the registration process before going in for final printing.

Recent Comments