How to balance Taggant with Ink- 1

How to balance Taggant

(Marker Ink) with Ink

– Simple Laboratory Test-

– I –

(Written by : N. R. Jayaraman )

(Marker Ink) with Ink

– Simple Laboratory Test-

– I –

(Written by : N. R. Jayaraman )

Many firms use the invisible markers (Ink) called Taggants mixed with the printing inks to add security to their documents as Brand protection measure. Most preferred medium of printing in such cases is Flexographic printing. In some of the countries the invisible taggant whose presence can be authenticated only by special gadgets supplied by the same taggant supplier is used by pharmaceutical and other consumer product manufacturers to print the cartons and labels as their products are more prone for counterfeiting. The printed documents on which the special ink is used includes metallic foils or cartons meant for packing the products.

The principle elements of the inking units (Taggants mixed with liquid alcoholic based inks for faster drying on the print medium) fitted on such printing machines are very simple and almost same except for design changes on the machines. Usually the medium meant for taking the print is fed only in roll form except in rare cases when the sheet format is deployed.

The principle elements of the inking units (Taggants mixed with liquid alcoholic based inks for faster drying on the print medium) fitted on such printing machines are very simple and almost same except for design changes on the machines. Usually the medium meant for taking the print is fed only in roll form except in rare cases when the sheet format is deployed.

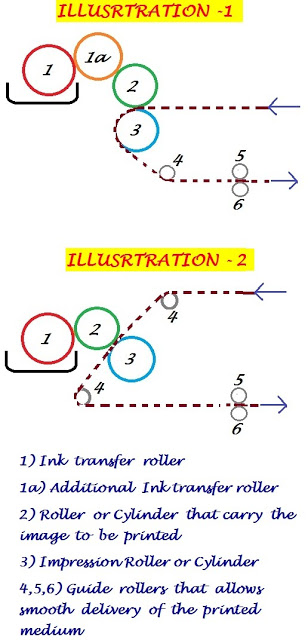

The inking unit on the machines consists of the following :-

- An ink tub carrying the liquid ink mixed with the invisible taggant powder.

- Ink Transfer roller which inks the plate that prints. The ink transfer roller usually is covered with some material like woven cotton fabric cloth similar to wool in texture that absorb the liquid ink and transfer it on to the plate. In simple word , the material used for covering the cylindrical shaped inking roller is something like rubber stamp ink pad which has some kind of fabric material carrying wet ink or similar to the fabric hose used in the dampening unit rollers seen on the Wet Offset printing machines.

- The ink transfer roller is usually ceramic based or polished steel cylinder tightly covered with thick fabric cloth .

- Impression cylinder in the form of steel roller that press the medium against the plate that transfers the inked image.

- In some cases the ink agitator is also found fitted in the ink duct to continuously stir the ink to ensure that the taggant powder do not remain as sediment in the ink tub as the size of the particles are very very small and require to travel with the ink to stay on the print medium for detection purpose.

The following illustration will explain the model inking system as narrated above.

In order to verify whether the taggant freely flows along with the ink to print and produce desired level of readability for authentication, and whether the strength of the taggant continues to remain within readable range throughout , simple offline testing should be conducted to ensure mixing correct proportion of the taggant with ink since the taggant is very costly. The effect and behavior of the taggant can be verified by conducting the following Laboratory experiment offline before finalizing the quantity of the taggant to be added with the liquid ink. Generally the particle size of the taggant should be very fine. Read in the last the particle sizes required for various processes. This experiment will save the time wasted on the machines for testing and also prevent wastage of the print material.

……….to be continued

Recent Comments