Alphabet- B/2

15. Bar Code Printing: A barcode is a machine-readable printed image consisting of parallel lines each varying in width or thickness. Though the image appears to consist of plain lines in different thicknesses, each or pairs of line contains inbuilt information about the item to which it is attached, which can be read by a machine readable scanner device. There are one or two dimensional lines, consisting of dots or hexagons that represent specific data. The Bar Code was invented in the US in the year 1952.

The traditional Bar codes are made up of a series of narrow and wide bars, with varying spaces between them. They can be scanned using photo sensor which read the barcode to show the text within. The scanning calculates the measurements between each bar, their thickness and space and translates those measurements into characters. Each pattern of bars in the code is represented by a character. All Bar Codes commence with a unique start character and concludes with a unique stop character. By having the Bar Code laid out like that, the scanning equipment can determine which way the code is scanned in, whether forwards or backward or vice versa

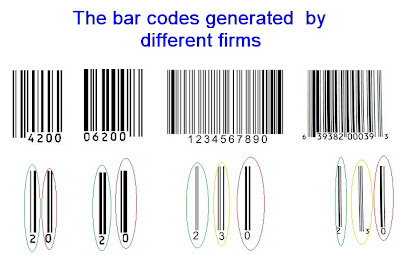

Originally Bar Codes represented data by varying the widths of lines and spacing of parallel lines to enable each firm to generate their own coded bars with the use of a Bar Code generator which allows creating a Bar Code graphic by providing Bar Code data, encoding type, and output file format. The Bar Codes are printable on the printing machines as well as by Digital printing. While there are many Bar Code types, they are generally categorized as 1D and 2D Bar Codes and choosing the right one depends on the needs of the business, the size of the product, label size and the amount of information that needs to be encoded in the Bar Code.

Bar Codes speak a different language in revealing the encrypted data and each type of Bar Codes differs in terms of linearity and capacity, making each one of them suitable for use of specific industry. While some of the Bar Codes are region (Country) specific and can not be scanned by scanners in other regions, the Universal Product Code can be scanned in many countries including the U.S., Canada, U.K., Australia and New Zealand.

See illustration below for example which shows different line widths and space for some of the numerals. Ex 2, 3, 0 etc . The barcode generator allows you to create a barcode graphic by providing barcode data, encoding type, and output file format.

16. Bleeding Ink : Bleeding ink prints in black but when exposed to any aqueous solution it will produce a red stain. Authenticity of a document can easily be tested without the use of any special agents.

17. Bench Marking : Bench Marking means assessing the efficiency of a unit to improve their working compared with other units whose efficiency in several areas of working are considered as the best practice followed in the industry.

In this respect the quality ISO certifications acquired by the industries gives them the best industry bench mark and whose practices are naturally compared for bench marking.

The general factors that determine the best working relates to the procedures followed by the most successful industry some of which are :

- Proper budgeting and accounting procedures to run the unit

- Planning the schedules much in advance and monitoring the results.

- Trimming the processes and procedures to be more responsive to customer demand and focus on superior customer service.

- Year by year reduction in expenditures and increase in efficiency by bringing continuous improvements in the working

- Modeling and optimization through development, integration and implementation to usage.

- The cost effectiveness in production by identifying the overlapping and repetitive exercises to cut down the expenditure to reduce the product cost

- Minimizing the manual work with mechanization and contracting in the areas possible.

- Integrating multiple locations together via a flexible Web interface for faster exchange of commands thereby reducing cycle times of the decisions from a couple of days to hours.

- Constant process measurement and report generation by a group to take corrective action on time.

- Standardizing and simplifying the work procedures

- Stream lining the Procurement procedures that reduce the cost

- Standardizing the products purchased.

- Spare parts management which reduces the cost

- Stricter Quality control measures that prevents wasteful inputs and rejections thereby reducing the cost

- Greater operational efficiency like deployment of minimum best workers and getting maximum outputs.

- Enhancing the efficiency of the workers by motivation and in-house trainings

- Re modeling the procedures to follow the best procedures noticed wherever it is possible to reduce wastage of time

- Safety measures including adhesion to the internationally accepted norms in environment safeguards by controlled discharge of wastes and effluents.

18. Banknote paper: Specially prepared 100% cotton rag pulp paper inbuilt with several overt and covert (hidden and open) anti counterfeit security features. Each paper mill manufacture country specific paper for Bank Note Printing. Bank Notes are also called Currencies or Paper coins. They are hard-wearing, age-resistant, and super calendared. The paper has country specific technical parameters suitable for multi color printing with a genuine watermark. They are supplied to suit web printing or sheet fed machines.

19. Bible paper :This variety of thin paper is manufactured with wood-free, low percentage of rag pulp with a low mass per unit area and with a high filler content so that even small prints will appear sharper. Bible paper must exhibit very good mechanical properties and high resistance to aging and are thin.

Recent Comments