Alphabet V

1. Varnish: Varnish is a colorless oily and or liquid product which has several applications in printing.

- It is one of the material added with the printing inks to reduce the tack.

- The Varnish acts as the carrier medium of the ink.

- This is used as over print medium over the printed images to add gloss to the print.

- This is used as protective coating on some of the Papers like Kraft and cover papers.

- This acts as protective coating on the printed surface and prevents the images getting scratched.

Though different types of Varnishes are available, the ones prepared from Resin and Linseed oil is widely used in the printing industry for making inks. The different types of Varnishes used in the printing industry include high gloss quick drying over printing colorless varnish and Oil based varnish. The varnish can be Glossy, Matte or Satin giving variety of finishes.

Offset varnish has modest gloss and is mainly used as protection for printed materials to prevent ink rub-off on printed matter. The varnishes used for overprinting on the printed sheets will require to be of quick drying in nature. Such Varnishes can be seen applied on the Book and Magazine front covers, Greeting cards, Invitation cards, Photo Books, Leaflets and Posters etc.

The success of varnishing and lamination always depends on the quality properties of the printing base. If the surface of the base material is smooth and dense, the end result will be excellent. Porous and uneven surface paper are not suitable for varnishing.

Varnishing is done through roller coating process. It can not be manually done. The printed sheets will pass through a bed which will be in contact with a set of rollers that will evenly apply Varnish over the printed surface. The Varnishes can be applied online or Off line i.e while the print is still semi wet or after the prints completely dry. Each method of applying varnish has its advantages and disadvantages. If the wet ink is not compatible to the type of varnish used, it will rub off the printed images thus making them unsharp. The varnish coating can affect the ink color and may alter the appearance of the ink. Varnishing has restrictions too. It can not be used on all the jobs and are meant only for certain jobs mostly where the illustration needs to be enhanced in appearance.

2. Variable Data Printing: Variable data printing means by making certain changes in the already compiled or printed design, or text material or combination of both. Several jobs can be printed at short time without need to re compose or re compile the entire print design. This is one of the best technique employed in Digital printing process like Desk Top Printing, and on demand Printing services where several jobs can be printed without stopping the machine for change over. Therefore the Variable data Printing is popular technique employed for printing of advertisement material, campaign circulars, personalized letters to many members, brochures, promotional documents etc.

3. Vignettes : The decorative and Ornamental designs are called Vignette. A vignette is a design element that is created in such a manner that the Vignette designed will merge into the surrounding design elements without showing definite border zones or elements distinctly. They are used for designing old ornate cards, antique designs, menu frame in restaurants, act as symbol, book borders, invitation cards, Greetings , backdrop of Palatial buildings etc.

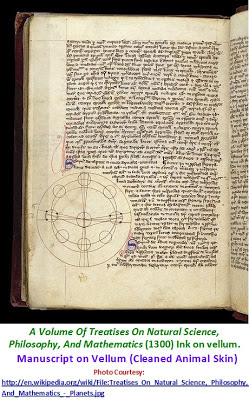

4. Vellum Finish : Before the paper was made, thin skins peeled off from the animals were cleaned and used for communication of text material. The skin will be well washed and sediments of flesh removed, surface smothered and dried as flat surface sheet and messages will be written on them for communication.

The cleaned skin was called Vellum. When the paper was invented and made with several finishes, one of the finishes of paper made that resembled the Vellum surface both in colour and texture was called the Vellum finish. The Vellum finish paper comes in different thicknesses, rough and smooth finish, and manufactured with Opaque and Translucent surface. Later years the Vellum was known to be called as Parchment papers.

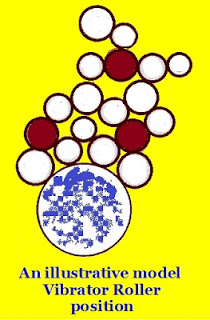

5. Vibrator roller: The vibrator rollers are nothing but the oscillator Rollers which in the ink chain of rollers determine how much ink should be applied to the plate while printing. The vibrator alias oscillator rollers are part of roller chain in Inking system of both Letter press, Offset and Other printing machines as well as Dampening system in Offset machine. As the name implies they oscillate laterally- which can be adjusted- and grind the ink well and make the ink film flow evenly.

In the Ink chain of rollers though has several rollers occupying various position and whose total quantity depend on the type of press, the role of the vibrator roller is very important. Generally the vibrator alias oscillators are found above the form rollers which supply the ink to the plate. The vibrators are also positioned in the mid areas of the supply chain to ensure that the ink received from the duct rollers is evenly spread on the rollers before reaching the form rollers.

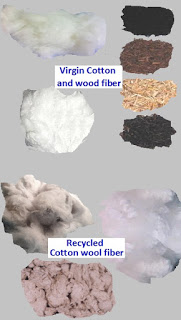

6. Virgin fiber: Virgin as the name indicates means totally fresh, unused before. Therefore the fresh fibers material like wood chips, Cotton Rags etc used in the Paper making pulping process are called Virgin fibers. The Virgin fiber Paper is made for high quality and durable Paper. They are called Virgin fibers because every time the pulp is made, only fresh stocks of fiber material is added in the pulp without mixing any fiber material from the recycled paper trimmings. Usually in the Paper making process, the 100 percent all good pulp is also mixed with some proportion of recycled paper trimmings to reduce the manufacturing cost while manufacturing the Paper. Such a pulp mixture will have both fresh and re used fiber material.

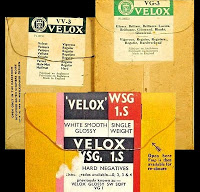

7. Velox : A special quality photographic printing paper similar to Bromide paper for making black and white contact photo prints from the negatives. While the films were made with Silver halide coating, the Photographic Papers were made with Silver Bromides and hence they were called Bromide Papers. This was developed by Eastman Kodak film company a photographic paper that could be processed under artificial light. The prints will be made using yellow lighting as safe light while processing them. The Paper was supplied in various grades to suit several jobs.

8. Viscosity – This describes the degree of fluidity of a liquid ink as far as printing is concerned. Viscose means the thickness. A high viscose ink means the ink is thicker and does not freely flow. Each variety of ink is made in different viscosity to suit the process and the substance or Paper for which it is intended. The Ink meant for Letterpress printing may not be suitable to Offset printing and vice verso.

9. Volatility: The property of the liquid in the ink that will evaporate during the process of drying after printing will show how volatile the solvent used is. While the spirits, alcohol etc used in Plate making for developing the Photo polymer processes are highly evaporating liquids, the solvents added with the ink for drying are slightly slower in evaporation. In the ink making process the volatility of the solvent which is used as assisting carrier medium is an important consideration in the manufacture of a printing ink that has been formulated to dry by evaporation process.

10. VOC: This term is abbreviation of Volatile Organic Compounds which are some of the petroleum product derivatives used as the vehicles for the printing inks manufactured for different process of printing.

Recent Comments