Students Guide to Printing- 46

-Few objective Questions and answers-

187) What is Digital Offset Printing and what is the difference between conventional Offset and Digital Offset process?

In the Conventional Offset printing process the image gets transferred from a plate to a blanket which finally transfer it on to the paper instead of directly printing the image from the plate to paper, is called Offset printing. This is one of the three main processes in Printing. The Offset printing again has two divisions which are called Wet Offset and Dry Offset printing. In Wet Offset printing the printing plates have the images and text matter in plain surface. They are neither in relief form, nor etched inside the plates and are in the same surface level of the plates.

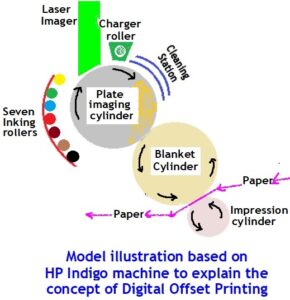

Digital offset printing is a new generation of ultra-high speed Digital Offset print technology that involves the electrostatic charging of an imaging plate whose discharged areas receive the ink which is then transferred to a heated blanket, then to the photo drum and finally to the substrate on which prints are made. It was unveiled in the Drupa exhibition by an Israel firm.

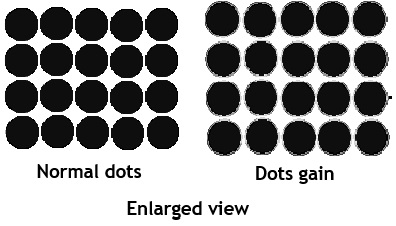

Digital Offset printing optimized to be efficient for high volumes for a variety of job, produces beautifully printed brochures, flyers, reports, postcards, and several more jobs using electrically-responsive unique ink, called ‘Electro Inks’ a proprietary product, with a specially-developed thermal transfer process using ultra-high performance multi-beam laser scanner and image processing software. The basic advantage of the Digital Offset printing machines lies in the superb quality prints of high resolution and brilliant colour with the look and feel of Offset printing, which is achieved by the combination of Electro Ink’s high saturation qualities and extended colour gamut. As the liquid ink pigments are significantly lower than those of powdered toner, it produces better print quality and better adhesion to various printing bases.The very small ink particles form extremely thin ink layers on the images – less than one micron thick – enabling both high quality and low cost.

The printed image is created directly on the plate from digital data. Unlike conventional Offset printing processes, where plate making process is involved to prepare the plate required for printing, this process involve no pre-press processes between the digital document file and the final print. Indigo’s process is fully digital from creation to print. And since it is fully digital, every image can be varied, enabling each print to be unique.

The whole process is based on the liquid HP Electro-Ink unlike most other digital printing processes where the toner inks are available in the market. From the industry it is learnt that the development of this liquid ink is supplied by the Israeli firm called Indigo NV which is based on electro photographic process with liquid dye which was introduced sometime in 1993.

188) What is the difference between Digital Printing and Digital Offset Printing process?

- The images are directly printed on to the paper in Digital printing.

- In the Digital Offset Printing, the print is transferred through an intermediate blanket cylinder.

- In Digital printing both dry and wet toners are used as ink while in the Digital Offset Printing only liquid ink is used.

- Digital printing is convenient and highly effective printing process available with many printers, whereas the Digital Offset Printing process is available only with limited printers.

- The prints of Digital print will not resemble to that of an Offset print whereas the Digital Offset print copies resemble to that of an Offset print because the ink used is liquid ink.

Recent Comments