Guide to Printing Students – 22

-Few objective Questions and answers-

Written by : N.R. Jayaraman

Pre note:-

The articles are meant to help the students gain knowledge and effectively compete in the interviews and nothing else. Please note that these are not to be published by anyone for commercial purpose without the written permission from the author since the theme and illustrative examples have been compiled exclusively by the author for the benefit of the student community. THIS WILL BE PERIODICALLY PUBLISHED.

100) What is Wet Collodion Process?

Wet Collodion Process is a film making process in Graphic Arts/printing. This term is used for the process in which the negative making process is completed with a freshly coated sensitive coating which will remain wet over the thin Glass plate on which it has been coated. Every time a fresh negative is prepared, the plate has to be freshly prepared by coating the sensitive layer over a glass plate before exposure. Not only the exposure is done when the coated plate (Glass plate) is still wet, but the developer and fixer process are to be immediately carried out after exposure without allowing the sensitized plate getting dried. If the coating dried up, then the plate cannot be processed further as the developer and fixing chemical solutions will not act on it.

The Wet-collodion process, also technically called Collodion process has been invented by an Englishman called Frederick Scott Archer in the year 1851 when process films were needed for reproduction. At one period of time when photographic process films were not developed, the art of making negatives with Wet Collodion process was very popular amongst the presses engaged in the printing of Maps and Atlas which required very big sized negatives and dimensional stability problem were not encountered with the film on the glass plates.

101) How is a Wet collodion plate processed?

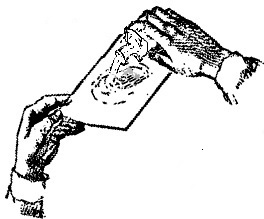

A fresh thin glass plate is well cleaned and first coated with a light Collodion. The glass plate is held at the lower left corner between the thumb and first finger.

The wet collodion mixture is first poured onto the center of the cleaned glass in one smooth motion to get an even coating on the plate. Once the solution is poured on to the plate then the plate has to be continuously and gradually tilted in each direction to ensure that the collodion solution flew all over the plate reaching each of the four corners of the plate and finally excess solution is drained out through the bottom right corner in to a beaker or some container. If tilting the plate to move the collodion flow to each corners is not properly done in one smooth even flow, then the coating will remain thick and thin over the plate like ridges in a field. Once the collodion is evenly coated over the glass plate, then the Collodion coated plate will be immersed in a solution of silver nitrate to form silver iodide over the collodion coating which becomes sensitive layer for processing. Then the coated plate is allowed to partially dry for few seconds to ensure that the solution does not drain within its base. In semi wet condition it is loaded in the camera shutter and fitted on the back side of the process camera to expose against the original.

Once the exposure is over, the shutter is again closed and taken to the dark room for immediate processing in the developer and fixer before the coating gets dried. Immediate developing and fixing are necessary because, if the collodion film is allowed to dry it becomes waterproof and the chemical solutions cannot penetrate into the film base. Once the developing, fixing and washing with plain water is done, the glass plate is dried and thereafter taken up for further use. Because all these processing is done when the plate is in wet condition, it is called Wet Collodion process.

102) What is Dry Plate Photo Process?

The Dry Plate Photo process is an extension and improved version of Wet collodion process. However it was initially invented mainly for the photographic purposes and not for processing as Graphic arts process films for printing purposes. This invention ultimately led to the development of Roll films for photography. The Gelatin material mixed with a sensitizer like silver bromide replaced the silver nitrate combined with collodion coating. The dry process was invented in the year 1871 by Dr. Richard L Maddox.

Contrary to the Wet Collodion process in which right from exposure to development and fixing, everything had to be carried out one after the other when the plate was in wet condition, the plates in Dry Plate process are done with dry plates. A glass plate coated with a sensitizer mixed gelatin is allowed to completely dry and kept ready for exposing against the original at one’s convenient time. Since the light sensitive coating remain dry on the glass plates it was possible to carry them to any external location for further processing. The exposed dry plate in shutter or packed separately (packing the exposed films in the dark rooms) in black boxes could be developed later in the lab at the convenient time of the photographer.

Recent Comments