Reprographic Processes- Origin and development

(Written by N.R. Jayaraman)

Photocopying, widely used by general public, business houses, education institutions, and other governmental departments is a process that facilitates replica of the originals through specialized machine called Photo copier, which in general is called Xeroxing.

The process of Xerox photo copying was reportedly invented in the year 1938 by an American physicist called Chester F. Carlson, a patent attorney in New York, though the world’s first photo copier in the name of Xerox machine was introduced by a U.S firm in 1960s. Prior to the invention of photo copiers, duplicating the originals were done by manual process involving carbon paper, exposing chemical coated paper, mimeograph machines and other duplicating processes, but the problem of copying the illustrations remained a big problem.

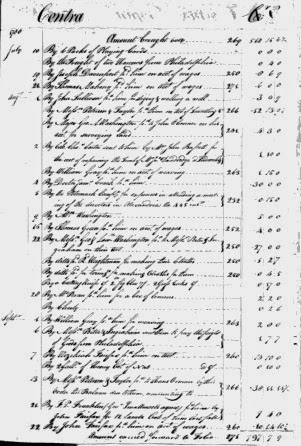

If one go through the history of copying they will be surprised to know that the copying of documents is not new phenomenon and was existing even during 2500 B.C. when scribes of Babylon and Egypt and copy clerks of Victorian era reportedly used quills, pens and small tools to copy the documents on to clay, papyrus material, parchment sheets etc for preserving information.

In the bygone era, say 500 to 600 years back the inscriptions found on the culverts and shrine walls were medium for taking prints by several historians and scholars, who were unable to take photo copies of the inscriptions (in view of lesser knowledge of photography in those days) for authenticating the texts found on the culverts or shrine walls. They used to rub charcoal on the surface and pressed semi moist paper on them to get prints for study and analysis in leisure.

As the time passed, instead of on clay, papyrus material, parchment sheets etc copying on paper commenced. Throughout 20th century, the photo copying in the name of Xerography remained one of the most sought after techniques by the industries and researchers for documentation purposes especially in Libraries and Universities. Fax machines, digital printing etc were offshoots of Xerographic process in later years. All theses processes come under the art of Reprographic Process. At one stage of time, the process of Xerox, the new invention in 1980s were part of Reprographic process and intended mainly for educational institutions, Research institutes, commercial and Governmental work.

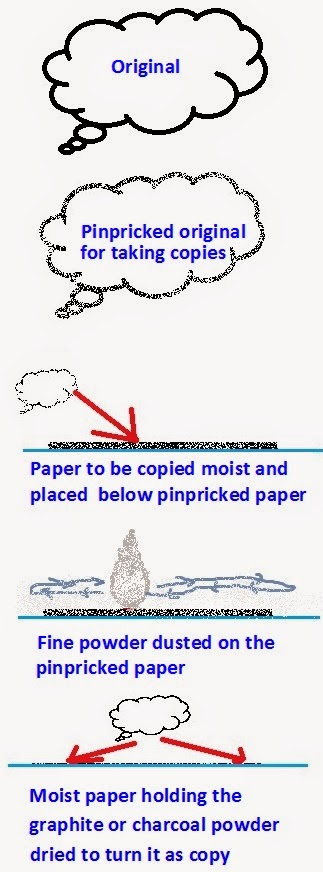

Prior to this, sometime during 15-16th centuries, some people practiced the art of copying in a different style. The original drawings were redrawn on to another paper using carbon like paper or a copy redrawn by the artists themselves and either of them, either the original or the redrawn copy were carefully pin pricked to create holes on the images to turn it into a stencil. Finely ground graphite or charcoal powder tied inside fine muslin clothes was dusted over the pin pricked areas to create image on to another semi moist paper kept below the pin pricked master to make few copies. The moist paper holding the finely dusted powders when dried held the image on to it thus remaining as copies. This practice led to the innovation of stencils in later era.

In the history of copying, the copying process played important role in the documentation of records and extensively used by the scientific communities and scholars all over the world for research and to study historical archives. The Engineers who drew the engineering drawings preferred copies to make corrections on the copies without destroying the originals for comparison. The copying process too helped in exchanging and circulating the messages especially during war time and to use the duplicate copies for litigation activities without destroying the original.

With the spurt in the research activities gaining ground all over the world, publication activities of research reports, scholarly journals and numerous other publications accelerated tremendously. Since one cannot be expected to keep the entire set of documents and only specific parts related to their scientific or research work may be required, copies of the specific pages from all such documents were preferred both for personal reference and to use as exchange material. It was also easier that the select copies thus obtained could be gathered, collated, classified or categorized and stored for retrieval at appropriate time for their relevant study. World over this facilitated the setting up of Documentation centers in the Scientific and Research institutions and to support the Libraries in the universities, colleges and schools etc which became the nerve centre for gathering information from the stored material. Some reprographic equipments or facilities were therefore needed in such places to instantly take prints from the culled material.

Reprographic techniques enabled one to obtain several or even a single copy from the culled original document, the photo copies that resembled the original in all respects including the contents in the original, baring the size so that they can be verified appropriately as and when needed. The second most important aspect of photo copying was that several of the documents were available in different languages and needed to be got translated from different places, the diagrams or drawings, especially the maps cannot be hand copied as even the minor error in reproduction can alter the subject. Therefore the reproduction of all kinds of documents cannot be done manually in entirety and some equipment or systems suitable to pick up and give true contents of the documents on another paper were needed whether one understood the language or not.

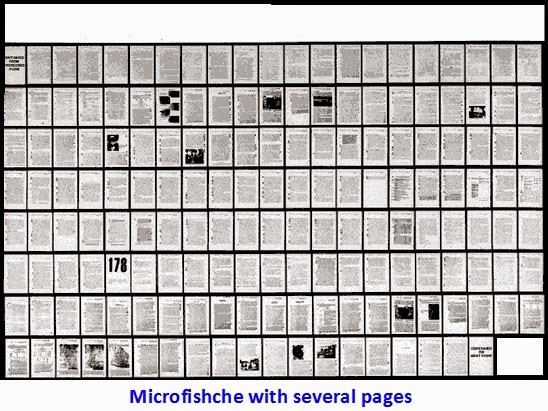

These factors lead to the ever increasing demand for the invention table top, time saving and quick to reproduce copying systems both for public use and Libraries and Documentation centers. Initially all the machineries and equipments used for these purposes were categorised as Reprographic equipments, Reprography meaning reproduction of documents. The initial set of eon back processes involved production of copies either in paper form or on storable, space saving films like Micro filming in 35 and 16 mm sizes and Microfiche which is a sheet of film, usually the size of a filing card, on which several pages of the books, newspapers, documents, etc, could be recorded in miniaturized form.

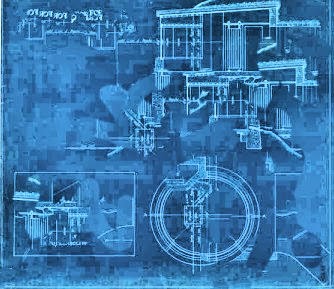

- Ammonia and Blue print process where in specially treated chemical paper is exposed under the tracing paper and the chemically treated paper put in the ammonia gas chamber to produce copies containing white images on blue background (negative image). They were mostly used for production of copies from Engineering drawings and Maps.

- Pellet Process is similar to blue print process, but produced positive image on paper. A paper sensitized with ferric salts is exposed to UV light under a translucent paper that contained images and then washed in ferrocyanide bath. A positive reading blue image in white background is derived from original drawing on translucent tracing paper, without requirement of an intermediate negative.

- Diazo process, again similar to Blue printing process, but involving paper sensitized with different other chemical called diazonium salts. The treated paper exposed under tracing paper and developed in ammonia gas chamber produce copies- Blue image with white background.

- Ferro Gallic Acid process is similar to blue print process that produces positive prints on paper. A paper sensitized with ferrochoride and tartaric acid and gum is exposed to UV light under a translucent paper that contains images and then washed in Gallic acid bath and water. A brownish print is derived from original drawn on translucent tracing paper, without needing an intermediate negative.

- Paperographic process where in a specially treated paper was converted into a stencil with special ink to reproduce multiple copies.

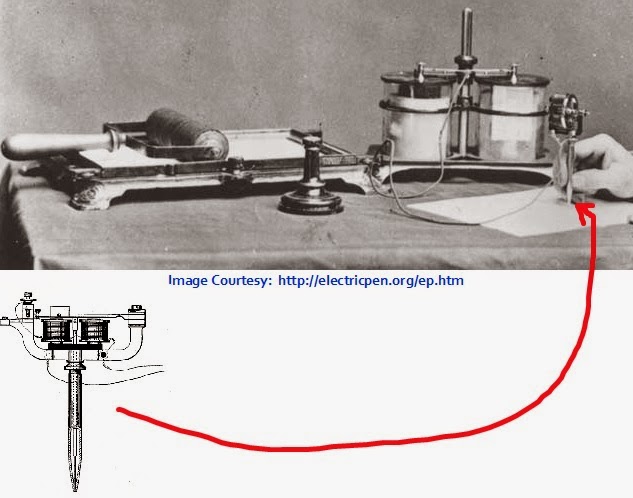

- Edison Stencils prepared using fine needle through a motor driven unit and then using it as stencil. The needle was called Edison electric pen.

- Heavy wax coated paper used as a stencil to cut the image with a hard nipped pen or knife to create pin hole and force the ink to pass through. This stencil was fixed on a machine called Mimeograph and copies taken. However the stencil could not accept the hand written text material.

Mimeograph process is another stenciling process. The matter is typed directly on a waxed mulberry paper without ribbon on a Mimeograph typewriter machine. The wax coating on paper gets removed thereby causing pinprick like holes in the areas of the text material. Once prepared, the stencil is wrapped around the ink-filled drum of the rotary or flat machine and Turkey Red oil based ink is forced through the holes onto the paper. Early flatbed machines used a kind of squeegee. This process was known as Mimeograph process.

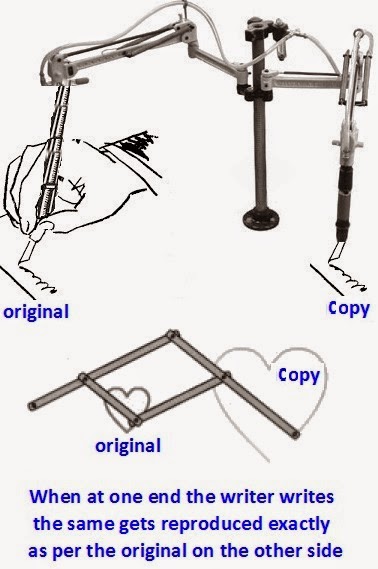

- Polygraph process in which duplication of the document is done with a second pen moving parallel to one held by a writer as it is written.

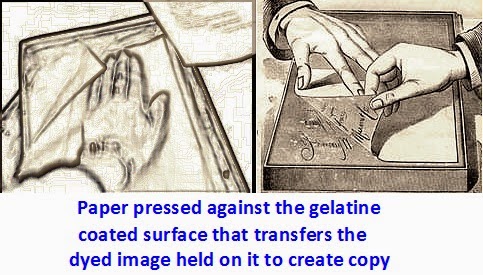

- Invented in Russia, the Hektographic process in which a master copy i.e. gelatine pad is imaged or written with special ink made of Aniline dyes. Then the sheets of fresh paper could be laid on top of the dye impregnated gelatine to transfer the image. This was good for short no of copies and was a slow process.

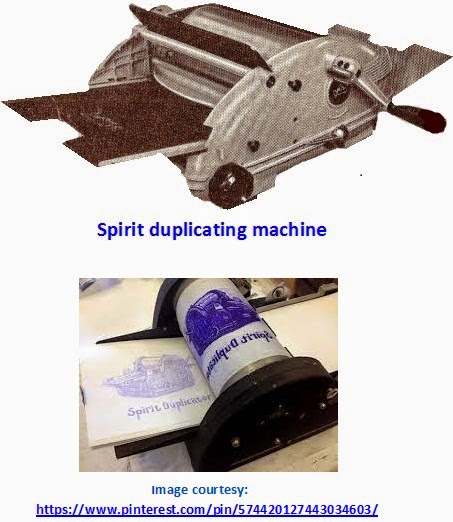

- This followed Spirit duplicating process called Ditto in which the the matter was typed or drawn on a special non absorbent, dye coated master paper. The image carrying paper was clamped on table top equipment fitted with a drum. With each rotation the moisture of the master sheet dissolved small faction of dye on to the paper producing copies, text material purple coloured. Often mistakenly referred to as mimeograph machines, spirit duplicators was invented in the 1920’s. Instead of ink, a solvent on each sheet of paper would dissolve some of the pigment from the stencil, with purple being a common color due to its better contrast.

- Photostat paper exposed through the process camera that produced white letters on black background. Since this could reproduce text to line work to illustrations it was used to take several prints for researchers for documentation purposes .

- Kodograph process in which instead of negative working Photostat paper the auto positive paper was used to get positive prints directly from originals, even from worn or weak tracings in ordinary room light without negatives. The paper was known as Kodak Photostat positive paper.

on white background (Positive print)

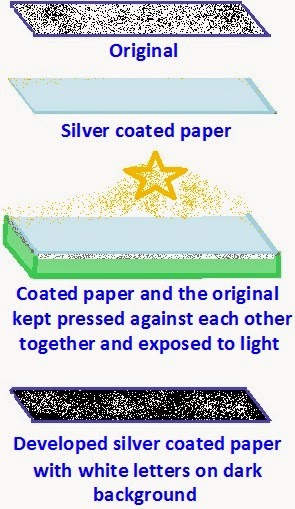

- A reflex copying process called Reflectography, in which a special coated silver gelatine paper is placed face down on the printed matter, pressed into contact and exposed through the back of the silver paper. The light passing through the paper is reflected back from the white surface of the documents and reacts with the silver coated paper. On development it gave negative image i.e. white letters on dark background.

- A duplicating process developed by 3M called Adherography in which the images were formed by the adherence of powder to a tacky latent image created by the effect of infrared heat. This provided a master from which 200 to 250 copies could be made. The powder image of the resulting print was fused to the paper by heat.

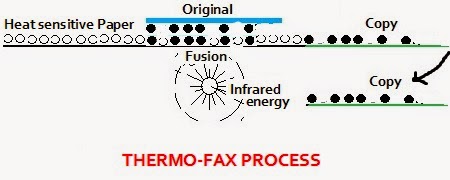

- Thermo-Fax photocopying technology is based on dry silver process introduced by 3M. A thin sheet of heat sensitive paper is placed on the original document to be copied, and exposed to infrared energy. The image areas in the original absorbed the infrared energy when heated and then transferred the heat on to the heat sensitive paper supplied by 3M thus producing a black image copy of the original.

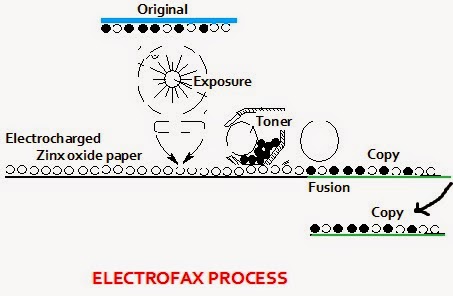

- RCA (Radio Corporation of America) introduced Electrofax which used Zinc Oxide coated paper that held the electrostatic charge similar to selenium plate holding the electrostatic charge. The original when exposed to the zinc oxide paper removed the charges from the non image areas and black toner particles adhered to the areas still retaining the charge and fused them to stick on to the paper thus producing copies with black image.

The second improvement made by Canon is on the Toner, a dry powder that forms the printed text and images on the paper on photo copiers and printers. The toner used on the copiers is a mixer of carbon powder, iron oxide, and sugar. The particles in the toner that form the images are melted by heat to bind the images on to the paper. Originally when the photo copiers were invented the particle size of toners used to be around 14–16 micrometers or little more. In order to further improve the print quality reductions in particle size to produce finer resolution prints were developed by Canon through the application of new technologies such as Emulsion-Aggregation. Toner manufacturers maintain a quality control standard for particle size distribution in order to produce a powder suitable for use in their printers.

Recent Comments