Alphabet R /2

8. Reprography : The term Reprography is a wide term that covers various processes including small Offset printing machines like Rota Print, Autolith, Multilith etc (Not bigger machines). Reprography in real sense means duplication of documents. They include written or printed matter, rare books, Engineering drawings, archives, designs etc and duplicated with processes that are based on or aided by photographic reproduction. Therefore Reprography is reproduction process -Reproducing by Photographic means- to convert the images into readable form, by breaking them into minutest dots, lines , pixels or other formats in real time sizes and images. Which one of the processes are called Reprographic Processes?

- Microfilm- Conservation of records to Micro reproductions on 35 mm films. Reason for doing so is for archival or other purposes, as a measure for preservation of records against deterioration from use or loss due to natural aging and fading of inks and further to save valuable space in keeping duplicate copies. They also help in safe storing of valuable records as a precautionary measure against loss by fire, flood, war and sabotage. The recorded version can not be read by naked eye as they will be in the form of minutest pixels. But the recorded information can be read only with an special enlarger which projects recorded information on a monitor screen. Micro form images are commonly reduced to 5 % of the original document size i.e an A4 size paper will be condensed to nearly 1’’x 3/4’’ frame in the film. For special purposes, greater optical reductions are used.

- Microfiche or Micro Card : Conservation of records on a 4’’ x 6’’ special cards of films. Reason for doing so is for archival or other purposes, as a measure for preservation of records against deterioration from use or loss due to natural aging and fading of inks and further to save valuable space in keeping duplicate copies. They also help in safe storing of valuable records as a precautionary measure against loss by fire, flood, war and sabotage. The recorded version can not be read by naked eye as they will be in the form of minutest pixels. But the recorded information can be read only with an special enlarger which projects recorded information on a monitor screen. An Micro Card or film in 4” x 6” size will hold 100-200 pages of an A3 size paper .

- Photostat : Several decades ago, till Xerox was introduced, all the photocopies were taken on a thin variety of special, but cheaper variety of Photographic paper called Photostat Paper using Process camera like copying machine. The Photostat paper in roll form used to be loaded on the Camera back and several documents will be loaded in the copy board and exposed through a prism . The exposed Paper will be developed with suitable chemical and washed with water and paper dried through drier cylindrical machines. The images will be white letters on a black background (like negative), but letters in readable form as the exposure will be done through prism for lateral reversal of the image. Both Positive and Negative working photostat papers were made available. All of them produced only black and white images and not colored.

- Duplicator: Duplicating machines using Stencil paper which are either directly typed or electronically cut Stencils were used for printing the images on paper. The images are formed by burning process in the the electronically processed stencil cutting machine to facilitate printing on duplicator.

- Ammonia or Diazo printing : By this process the architectural and engineering drawings, technical drawings etc drawn on tracing paper are duplicated on a photo sensitive paper even if the size is very big. The copies will be white lettering on blue background. The only drawback of these prints are that they fade away on constant exposure to light.

- Digital printing

- Inkjet printing

- Electrostatic processes (Xerox)

- Tabletop small Offset/Thermal printing: On these printing machines only paper plates (not metal plates) acould be used. The latest development by Mitsubishi in this direction is the Thermal Digi Plate TDP-459 for small offset printing due to be featured at drupa. This compact table-top system, according to the manufacturer is designed for 2-up printing, images paper offset printing plates without any consumables other than the plate material itself. The TDP system is an environmentally-friendly CTP system which is chemical-free and process less. Read more on this in their site by clicking : http://www.mitsubishiimaging.com

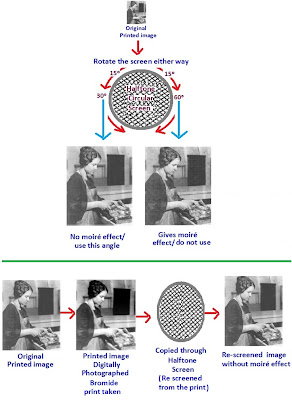

- If the printed halftone original is coarse one, the image is enlarged by 1 or 2 % and copied as line work without using a screen. Similarly the size is reduced by 1 or 2 % and processed. The reduction and enlargement is possible only if the change in the image size is permitted, because for certain technical reason or on account of scaled images, the reduction or enlargement may not be permitted.

- The second option is to focus the image on the camera back and see which screen angle will reproduce the image with less or no moire effect. If the camera is fitted with a circular screen, then the screen can be rotated to find out which angle can avoid the moire effect and then it can be copied. Generally the turning of the screen by 15º will considerably reduce the moire pattern. For example if the original halftone image has been reproduced with a 45º angle screen, then rotate the angle both sides by 15º to find out which one gives the acceptable image and then copy the image.

- The third option followed by many printers is, photograph the printed original with a digital camera, take a print out and then use it as original continuous tone copy for half-toning the image. However the ultimate goal is to copy as much detail as possible avoiding the problems of overlapping screens.

Recent Comments