Alphabet – P /5

22. Pre-sensitized Plate: The printing plates or the Offset Printing are made by exposing the plates with Negatives or Positives. In order to form the images from the negatives or the positives, the plates will have to be coated with some light sensitive material, dried and then exposed through the negative or positive and developed to form the image. The entire process is time consuming.

In order to speed up the process, some firms are supplying light sensitive Pre Coated Metal or Paper plates which can be taken out from the packed box and then directly exposed with the negative or positive, developed with special solution which forms the images on the plates. Such plates are called Pre sensitized plates. In Pre sensitized plates both negative and positive working plates are available.

One of the plates used in Printing is the specially pre coated Photo Polymer printing plates, meant for Dry Offset or Letterpress printing and which can be exposed with negative or positive and simply washed with water or alcohol to get the relief image. No special solution is necessary to process the plates. The light passing through the negative or positive polymerizes the image areas and harden them to become relief images which will remain insoluble in water or alcohol. They are then dried and preserved for printing.

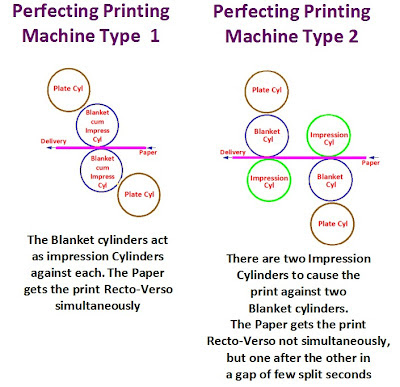

23. Perfecting Press: Perfecting means printing both sides of the sheet in one pass in perfect registration. Such a process that produces both sides print in one pass is also called duplex printing or perfecting. A sheet can be printed with any no of printing plates on both sides (even multi colour) which depends on the type of machine on which they are printed. The impression is derived by the blanket to blanket pressure instead of the impression cylinder causing the print to transfer.

Again there are two types of presses available to do the perfecting. One cause the transfer of impression on to the paper in one go by passing between two blanket cylinders each acting as impression cylinder against each other. The second type of perfecter allow the sheet to first take the impression on its first side, then travel to take the print on the other side and comes out. The mode of impression is as usual the impression cylinder causing the impression on to the paper.

In both the cases the once fed sheet comes out printed on both sides in one go , the only difference as pointed above is that in one case the sheet gets the prints simultaneously on both the sides while in the other machine, the sheet gets the impression on the other side in a fraction of seconds, but not simultaneously.

Rotary multi color perfecting machines for the simultaneous recto-verso (back and front) printing are used extensively by the Currency printing units because even the slightest paper stability can cause the see through register going awry causing mis registered image. Many such perfecting machines are also commercially available with different types of printing technologies, but the most common type of machines in use is the Dry Offset or Wet Offset Printing machines which print on individual sheets of paper, or web-fed configurations, which can print on long webs of paper supplies in large reels.

24. Photo lithography : Before one understand the Photo lithography concept, it is necessary to understand what is meant by Lithography. Ever since Alois Senefelder invented lithography in the year 1798, in addition to the letterpress printing, the printing was also carried out by Offset printing process which is based on Ink Water repellent theory. The text and images were manually created with grease crayons and oil receptive inks on the polished lime stones and printed through the blankets or even directly on to the paper by pressing the paper against the stone image using tough rubber based cylinder pressure. Images were also drawn on gelatin coated varieties of special papers called Transfer papers that had coatings like Starch, Gelatin mixed with Glycerin and even Plaster of Paris fine ground powders etc, and then the images on them were transferred on to the lime stone. The use of Transfer papers facilitated easy corrections without damaging the stone surface with frequent rubbing for effecting the corrections.

Later photo sensitive papers called Photo Litho Transfer Papers were also used and got exposed with negative and the resultant images transferred on to the stone. As further development, the Lime stone was also coated with some photosensitive material and exposed with negatives (Glass films) to harden the image areas so that they can be inked with some oily substances to make them ink receptive for use as plate. This is known as the Photo lithography or Photo lithographic process.

Photo lithography is a general term that refers to photo mechanical application with and without the use of half-tone processed images to print by Lithographic process. The Lithographic process culminated into Photo Offset process in which the images were formed on several light sensitive coated metals like zinc or Aluminum plates using negatives and positives to to prepare metal plates instead of Litho stone for printing by Offset Process. So the term Photo lithography came up to such processes.

Another school of thought explains the Photo lithography as lithographic process by which the design of circuit paths created on some substrate materials called Masks or Wafers were transferred onto the printed circuit boards either directly (without using a mask) or with a projected image and then etch them with some suitable etching solution to to make the printed circuit boards.

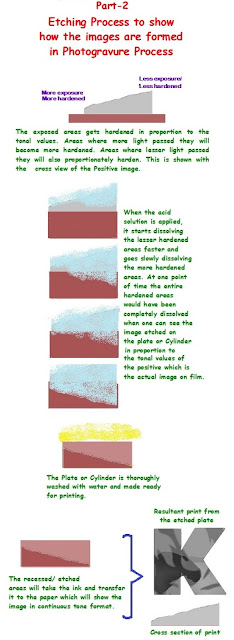

25. Photogravure : Producing the gravure printing process plates in combination with photographic means is called Photogravure. Photogravure is a photo mechanical process for making plates to print resembling the continuous tone photographs. The Printing plates for this process is prepared by etching photographic images on to a copper plate or a cylinder. The etched areas of the plate or the cylinder hold the ink and transfer them on to the paper. This process can produce high quality prints and also lmeet the requirement of larger quantity of print.

Basically the Copper Plate or the Cylinder is coated or treated with some light sensitive photo material and then exposed to UV light with a film positive containing the images of the photos to be reproduced. Another method suggests the use of light sensitive coated gelatin be used instead of directly coating the plates or the Cylinder with the light sensitive material. After exposure, the exposed plate or the Cylinder is washed well in hot water that wash away the coating on the unexposed areas in proportion to the hardened structure (see illustration to understand this). Then the plate or the Cylinder is etched with suitable chemical which eats away the portions of the copper metal in proportion to the highlights, shadows and middle tones. The ink will then be applied to those etched (recessed) portions and when transferred on to the paper will create print similar to the photograph.

No Photographic halftone screens are used to cause the photographic image with tonal variations. However some commercial presses are using special dot screens to produce the images in halftone. Different types of Photo mechanical cum Chemical processes or techniques are available to make such Copper plate or cylinder with Photogravure image. This process is extensively deployed for printing the Postage stamps. The Photogravure process is also deployed for printing weeklies or monthlies with mass circulation that carry lots of photo images and illustrations.

………..Additions to alphabet P to be continued under P/6

Recent Comments