How to balance Taggant

(Marker Ink) with Ink

– Simple Laboratory Test-

– II –

(Written by : N. R. Jayaraman )

SIMPLE PROCEDURE TO TEST THE EFFECTIVE WORKING OF THE TAGGANT VIS A VIS THE INK – TAGGANT RELATIONSHIP

The lab testing procedure for Ink – Taggant working involves the following steps.

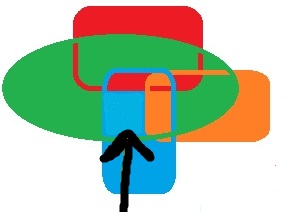

1) Prepare two small metallic hand roller say 2” to 3” wide (see illustration). Tightly cover one of them with the same kind of fabric cloth used on the ink roller fitted on the Flexographic printing machine for which the ink is meant to be supplied. The other roller will be used as impression roller.

2) Then apply ‘x’ quantity of liquid ink (same as used on the printing machine for which the special taggant is supplied) mixed with the taggant on the hand roller. Both the taggant and the liquid ink should be same as proposed to be used on the machine, lest the lab test may not truly reflect the result .

3) Once you have dampened the roller with the liquid ink containing taggant, roll it over on some smooth flat surface base like steel or glass plate to ensure that the liquid ink gets spread into the fabric sleeve without showing patches on its surface. This also ensures that the ink gets spread uniformly on the roller carrying ink .

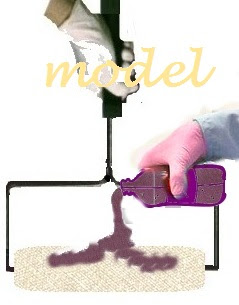

4) While the hand roller is still wet with ink, apply ink on to a rubber stereo model plate and take 4-5 prints on the sample paper or medium to be actually printed. Apply pressure over the paper or print surface with another empty metallic roller already kept ready.

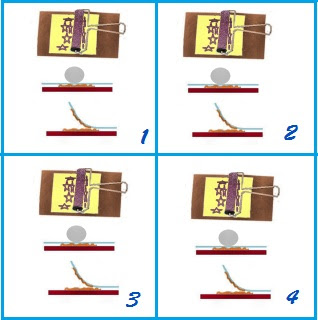

Without recharging the hand roller again with fresh ink , take few prints each time applying the ink from the same non recharged ink roller to examine the quality and quantity of the print produced.

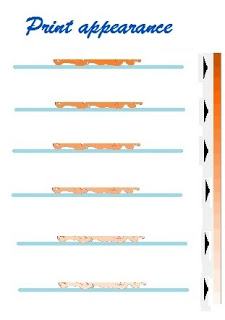

This process will show whether the taggant has been properly and uniformly transferred on to the foil or the print surface along with the ink to give desired level of readability on the special Gadget that reads the presence of minimum ‘n’ no of particles to authenticate the genuine product.

5) After taking few prints add same ‘x’ quantity of diluted liquid ink (without mixing the taggant) on to the inked roller say once , twice or thrice and take further prints to examine whether the strength of the taggant still remain the same or to what extent the strength has gone down .

6) This test is important for two reasons. The analysis of the print thus taken will indicate whether the taggant mixed in the ink gets fully transferred on to the print surface or partially stick with the fabric fixed on the inking roller.

7) After analyzing the prints thus taken as stated under Serial No 4 and 5, allow the roller to dry and then examine whether any dried powder particle falls from its surface. There will always be some amount of dried powder particles say 2-3 % sticking to the surface . But it should not be high which may otherwise fail the use of the taggant for authenticating with special gadget . The second factor is the concern that the dried powders may fall and clog the rollers bearings or some moving parts of the machine.

Once it is confirmed that the taggant powder gets transferred freely and fully from the cloth covered inking roller, it should not cause concern and actual machine trial can further be conducted with full settings. If the initial lab test itself show high percentage of the dried taggant powder on the rollers or sediment in the ink duct , then it means that the taggant has not mixed well with the ink and the particle size of the taggant needs to be adjusted for smooth working.

—–to be continued

Recent Comments