Guide to printing students

-Few objective Questions and answers-

Written by : N.R. Jayaraman

Pre note:-

The articles are meant to help the students gain knowledge and effectively compete in the interviews and nothing else. Please note that these are not to be published by anyone for commercial purpose without the written permission from the author since the theme and illustrative examples have been compiled exclusively by the author for the benefit of the student community. THIS WILL BE PERIODICALLY PUBLISHED.

63) What is Aqueous Coating?

It is a water base clear coating which is done on the printed stock not only to protect the print, but also enhance the appearance. This is done through the paper coating machine and the clear coating provides high-gloss surface that deters dirt and fingerprints and improves the durability of printed material as they are handled. It also looks beautiful on brochures, catalog covers, and stand-alone flyers.

64) What is banding defect in the printed image?

This is a print defect that sometimes appear in halftone screen tints when the print is taken on a laser printers, image setters, or plate setters. The defect will appear on the print in the form of parallel streaks on the images.

65) What is a Caliper and its use ?

It is a tool used to measure the thickness of the paper stock and its value expressed in terms of microns (millionths of a meter). Variation showing ± 5% in the figure arrived at different places with different calipers is normally acceptable in international standards.

66) What do CMYK represent ?

It is related to the sequence of colours used in four colour printing process. It indicated the primary colours such as Cyan, Magenta, Yellow and Black.

67) What is Colour separation process in printing ?

It is a Graphic arts reproduction process of converting the coloured originals into printable plate for the printing machines. Normally the coloured originals are converted into three or four colour printable plates using colour filters and halftone screen in different angle. In this process the multi tonal coloured originals are converted into tiny bit of dots of varying sizes to match the shades in each colour. When the thus separately converted plates are printed using CMYK or CMY colours one over the other, the resultant image will match the colour original. This is called colour separation process.

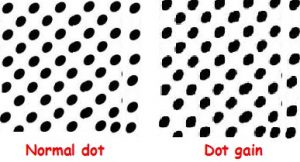

68) What is referred as Dot gain in a printed sheet ?

It is a phenomenon in printing which cause tonal value increase to make the print appear darker which occurs ink mismatching to the stock of paper is used for printing and the base oil in the ink is absorbed by the paper showing the printed dot appear slightly bigger than the image on plate. Such an appearance of ink dot –enlarged appearance- due to absorption by the paper is called dot gain.

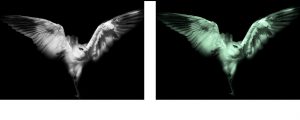

69) What is Duo-tone printing ?

Converting one colour or black and white original into two coloured original in printing by use of two different plates made with two halftone negatives-each varying by 15% in angle. Such printed images will appear as if the original was also two coloured one. This is called Duo-tone printing process.

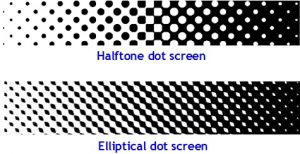

70) What is the difference between Halftone dots and Elliptical dots ?

While reproducing an original by printing process, the original need to be first converted into printable form by splitting the various shades in the original into varying sizes of dots. This is done by reproducing printable plates using halftone screen. In this conversion process, the conventional halftone screen produces circular dots of various sizes. Similarly the other special halftone screen used is Elliptical screen which produces the dots in the shape of elliptical dot pattern and not circular dots. Some of the originals, especially the black and white and Duo-tone originals give better print effect when they are printed using elliptical screen.

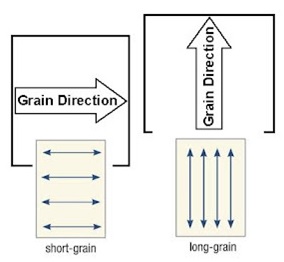

71) What is short and Long grain paper?

During paper manufacturing process the paper whose fibers run parallel to the long dimension (running length) of the sheet is called long grain paper and the paper whose fibers run parallel to the short dimension of the sheet is called short grain paper.

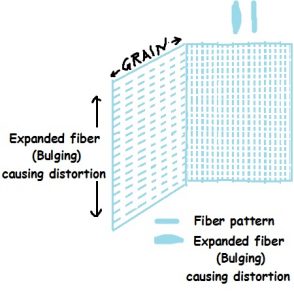

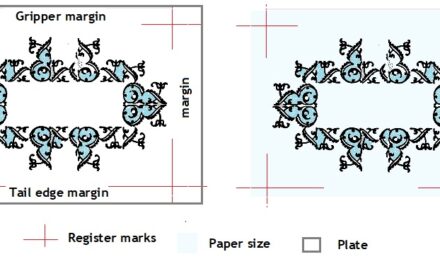

72) How important is the grain direction in printing ?

Grain direction i.e cross-grain direction and long-grain direction is an important consideration while printing multi colour reproduction especially in sheet fed offset print process since the sheets will have to maintain true dimensions for perfect registration. It is the tendency of the paper fibers to absorb water from the atmosphere if their moisture content in them is less to the room temperature. Normally the sheets expand in width, but not in length. Because the direction of greater dimensional change will be in the cross-grain direction, long-grain paper (fibbers floating along the running length) is generally preferred for offset printing process to ensure that the dimensional stability of paper is maintained for perfect registration of colours. However for single colour work the grain direction is not a concern.

Recent Comments