Students guide for Printing – 39

-Few objective Questions and answers-

Written by : N.R. Jayaraman

174) What are the advantages of water based inks over oil and solvent based inks and where are they used?

The water based inks are cheaper and easily washable from the rollers thus reducing the machine down time. There will be no odor of chemicals. They are particularly very good inks for printing by Silkscreen and Flexo processes on low quality fabrics and packing cartons as they easily penetrate into the fibers or get quickly evaporated or absorbed by the medium on which it is printed. The disadvantage is that they are not useful to print on non-absorbent materials. Water-based inks are completely free of PVC resin or plasticiser, free of harmful ozone depleting chemicals, aromatic hydrocarbons and therefore remains most Eco-friendly inks.

The plastisol inks are prone to cracking and fading and thus gets washed away as they remain on top of the medium like fabrics or garments on which they are printed whereas the water based ink print last longer on the same medium.

175) What types of materials are used for silk screen stencil and state their advantages and disadvantages.

Various materials such as Silk, Synthetic such as Polyester, Nylon and Metal fabrics are used as screen stencil material. Traditionally coarsely woven silk cloth were used as stencil material. It was not dimensionally stable and did not suit the multi-color registered jobs.

Polyester material, made of synthetic material is strong, dimensionally stable and strong, but unfortunately they do not hold the coating well and cause several technical problems like proper ink transfer from the stencil unless proper inks are used to suit them.

Nylon is again synthetic material, strong and durable to give good registration. This is widely used by the silk screen printers.

The latest development has been use of metallic screen which is found to be highly dimensionally stable, give longer life and work well.

176) What is ‘Discharge ink’ and in which process they are used?

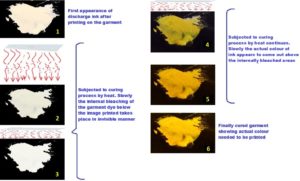

Traditionally plastisol inks is used for printing on garments by the Silk screen process of printing. However using special inks called ‘Discharge ink’ which is water-based ink mixed with special chemical agent, the dark garments are printed by Silkscreen process to get softest and brightest print than what would be obtained in regular printing. This process is shortly called discharge printing.

The special discharge ink for printing on the garment is prepared by adding a discharge agent. After printing the additives in the ink first remove the dyes of the fabric like bleaching but by invisible action and ensure that the desired colored ink sit over the bleached area under the design elements. Discharge printing is actually screen printing process where the same techniques and equipment are used but instead of normal ink, discharge ink is used.

The removal of the dye (original colour of the shirt) from the garment mean actually bleaching the dye below the design printed with a specific colour before the actual colour begins to surface. The special discharging chemicals components mixed in the discharge ink reduce the intensity of the base colour of the garments – an effect of bleaching- under the areas of the design before allowing the actual colour with which it has been mixed sit over in those portions slowly gaining the true shining colours. Because of the bleach action, the brightness and softness of the colour printed give enhanced colour feel. At the same time the chemical mixed with the discharge inks doesn’t in any manner damage the fibers of the garment. After the garment is printed, the printed garment had to be passed under heat chamber to allow the bleach function of the discharge ink to begin.

While plastisol ink sits on top of the substrate (garment) which can be felt by the touch of hand , the discharge ink gets absorbed into the fabric without giving feel to touch. Printing discharge ink on 100% pure cotton garment will give best result. Garments with black polyester is reported to be not best suited to print with discharge ink because the discharge chemical will not be able to strip the base colour from the polyester material.

177) What is Expanding ink ?

Expanding ink also called puff ink is group of ink under plastisol ink which is added with special additive like heat reactive foaming agent which when printed by silk screen process gives relief of the print over the garment similar to 3D effect after drying. The ink after printing expands on the surface on which it is printed when exposed to high temperature heat when the garment is cured. This action of giving relief or embossed effect is given by the additive added in the inks. The embossed print seen after drying looks similar to rubber print on garments.

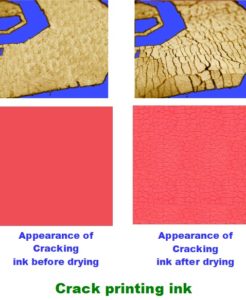

178) What is called crack printing ink ?

Crack printing ink also called shatter screen printing or distress printing is a screen printing process to print on the garments that produce prints resembling to Rubber prints. The cracking ink is water based ink. But unlike Rubber print ink, the Crack printing ink self-cracks on the printed surface after the garments are heated for curing the garments. The cracked effect is desired to give the printed garments unique vintage or antique look or designed to appear so on the t-shirt, sweat-shirts or jacket or any other apparel.

Recent Comments