Guide to printing students – 4

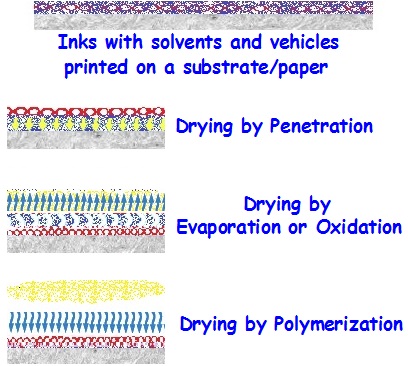

- Oxidation process in which the substances like vehicles and driers present in the inks facilitate drying by absorbing oxygen from the air and chemically reacting to become hardened particle at the same time holding the coloured pigments remain on paper surface.

- Penetration process in which part of the solvents and vehicles present in the ink intrude into the surface of the paper while the remaining reacts with the atmosphere and solidify thus facilitating the drying of ink on the surface of the paper.

- Another chemical process by which the ink dries is Polymerization in which the substances present in the ink chemically react with the atmosphere and hardens the ink films to dry on the substrate on which they are printed.

- The next is Evaporation process in which the low boiling point solvents present in the ink gets diffused leaving the pigments to get hardened and remain firmly on paper.

- However some of the inks dry by penetration cum evaporation, some by penetration cum polymerization and some by oxidation cum polymerization process.

- Whatever is the mode of drying, the vehicle or solvent present in the ink indeed penetrate into the base of the substance and allow the ink to dry by any one of the processes mentioned above.

The general composition of printing ink is:-

- Pigment or colorant is the coloring agent added in the ink. The amount of pigment used determines the shade or colour of the ink.

- Vehicle, is the liquid that holds the particles of pigment together. The properties of the vehicle does not end with the binding of the pigment alone, but its chemical reaction with pigment can also influence the colour or hue of the ink. Further it determines the flow of ink.

- Driers or Modifiers, though control the drying properties of the ink is also responsible for the appearance of the printed colour on paper after the ink dries on its surface.

18) What are the properties of printing ink ?

The printing inks have optical, structural or runnability and drying properties. Optical or Visual properties of the inks are appearance of color which is the hue or shade of the printed image besides transparency, opacity and gloss.

The optical properties are:

- The colour of the ink which is termed as hue or shade in technical term. The amount of pigment used, the type of vehicle and drier added too contribute to the correct hue and shade of the ink.

- The opacity in the ink means the ability of the printed ink to hide the color beneath it. Generally ink requires small amount of opacity to create the secondary or tertiary colours when several colours are printed one over the other unlike opaque ink which completely blocks the colours printed below them. In some of the multi colour printing partial opaque ink is used and the extent of opacity is decided by the ink maker. The extent of vehicle used influences the opacity.

- Transparency of the ink is opposite to the properties of opacity of the ink which is actually needed for multi colour jobs. The transparent ink does not hide the color beneath them but mix with them to create supplementary colors. All the inks used for printing multi color work must be transparent ink. The extent of vehicle used influences the opacity.

- The term Gloss refers to the ability of the printed ink to reflect back the light from the surface on which they are printed. The extent of gloss depends upon the penetration of the ink into the substance on which they are printed.

20) What are the structural or runnability properties of the printing inks ?

The term runnability applies to the trouble free running of the ink on machine for which it was intended interacting with the paper, machine speed and drying time required. The body, length, tack, adhesion and type of drying of the ink contribute to the runnability factor.

- Body refers to the viscosity or consistency and softness of the ink. Viscosity influences the flow of the ink on rollers.

- Temperature stability refers to the quality of the ink in retaining their properties without affected by the heat generated by the friction of the rotating rollers and cylinders.

- Length refers to the ability to flow on the rollers. The ink makers term them as short and long inks. Short inks suit the low and medium speed presses while the long ink suit the high speed machines.

- Tack refers to the properties where in it will firmly stick to the rollers of the inking unit and not fly off from them. Tackiness in one way refers to the stickiness of the ink. At the same time it has to get transferred from roller to roller and then to the plate before getting transferred on to the paper. It should also not pluck off the paper fibbers after transferring the image on the paper.

- The drying properties of an ink is very critical for a number of reasons and no printed sheet can be further handled for onward processing unless the printed ink dries quickly over the printed surface. At the same time the drying should not alter the colour or shade. The drier is carefully added by the manufacturer taking into consideration the process to which the ink is used.

The pigment and dye both are meant for manufacturing printing inks. Pigment is used to make only oily based inks while the Dyes is used for making both oily and water based inks.

22) What is a non porous ink ?

The ink used for printing on plastics or metals are all non porous inks because they dry by oxidation process without getting absorbed into the surface of the substance on which they are printed. They need some kind of heat chamber or heating elements to facilitate drying before they fall in delivery pile to prevent set off.

23) What is Metallic Ink ?

The ink which are made mixing metallic powders such as aluminium and copper, bronze or some such metallic alloys alloys with the varnish base to give pleasing metallic lustre of the printed matter is called metallic inks.

24) What is Magnetic Ink ?

In order to enhance the security of the cheques issued by banks some of the contents in the cheques are printed with inks which have special pigments and which can be magnetised after printing. Those magnetic ink printed messages can only be read by special reader meant for each type of ink used. They are called magnetic inks.

Recent Comments