ERP

PART – II

( Written by N. R. Jayaraman )

Now a simplest Coding system has been worked out. Unlike previous system of listing the material division wise, then section wise and then group wise, an alternate simple system can be adapted as discussed below.

Stage-A

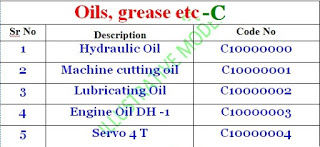

1. Group the entire items of the organization from ordinary pin to gem clip and bigger parts into major groups such as Stationery which includes paste and gum and even adhesive etc, then Furniture, Lightings and their fittings, Toiletries, vehicle spares, spare parts for machineries and equipments, all varieties of consumable material used in the plant for production purposes, Paper meant for printing Labels, common materials like Oils and grease, Petrol, Kerosene, Cleaning agents, Packing material etc to name a few. Create major groups like the above not exceeding ten to twelve. The list can be shortened taking into realistic conditions on the usage of the items because under each division there may be hundreds of items accounted, never bother to which department they belong to.

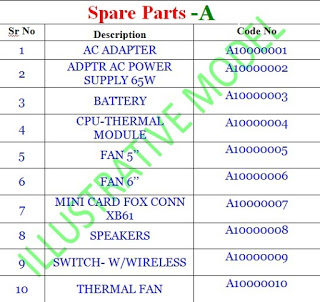

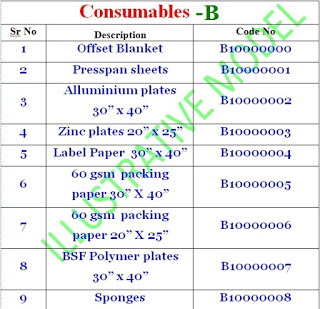

2. Make the entire list ready. Since it may take several days for compilation, with a team of people list out the material under each group, let the team sit together and finalize the divisions under which each item may have to be accommodated. Once the listing is done make the list in each group in alphabetical order and then start allotting unique codes with a common starting letter to each group which indicate the group to which the items belong. There is no need to divide the groups into sectional group. One issue will always cause working problem. There may be several items/parts which may have been procured under different nomenclature as they are not proprietary products in nature. Therefore while the list is compiled list the equivalent items under the same item/part as a,b,c etc. This is one major deviation in this system now suggested which will be easier to maintain and required data can be quickly generated. See the following illustrative list :

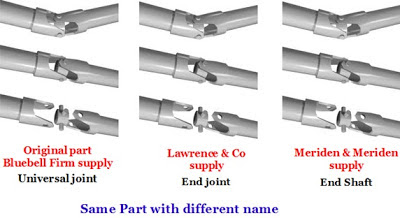

3. Let us see the case with the following illustrative example. An item called Universal joint of a particular size is used on the machine and frequently procured. The nomenclature of the item in the plant was ‘Universal joint – with xyz specification’. During tender process the same product – absolutely same in all respects- my have been offered by few manufacturers in the name of End joint and End Shaft . Question will arise as to how it should be listed- whether as End Joint or End Shaft? Undoubtedly it has to be listed as “Universal joint (a) Universal joint -End Shaft (b) Universal joint- End Joint”. How they will be entered in data entry and accounted will be explained while the process of input is discussed.

See how the above entry is made in SPARE PARTS -A.

——————————————————————————-

11. Universal joint A10000011

(A) Universal joint

(B) End Shaft

(C) End Joint

——————————————————————————–

Stage-B

5. What is the next step? After allotting the Code nos, the real challenge begins. You have to start feeding the following information in a diligent manner. However one very important point that needs to be taken note of is that once the listing has been completed, the ERP consultant will have to be associated in the subsequent operations because they will be able to guide how the input is to be done to derive the required output. What are the expectations in respect of the out put? This should be first discussed with the consultant since based on the said requirement only he can programme the whole thing. Never bother to several discussion with consultant to address the requirement and to understand the implications. If need be a demo can be called with four to five items and ERP studied thoroughly.

………..To be continued

Recent Comments