Alphabet- B

1. Backup: To print on the reverse side of a printed sheet. Also it refers to the replica of the additional copy being kept in another drive or pen drive or hard disc in computers as safety measure.

2. Binding: The process of fastening both loose printed and non-printed sheets into some sort of a book, magazine, students note books, writing pads, brochures, booklets, catalogs or any print books using coils, wires, staples, or some sort of good adhesive. This process is the last step in the press process before dispatch.

Binding also includes operations such as sorting out the good and spoil sheets, gathering the good sheets together/arranging the printed sheets in correct sequence which in technical term is called collating, then drilling small holes for stitching or stapling and finally cutting/trimming to desired size etc, if it is meant to be finished in a book format. Technically in a printing press each of these operations falls under Bindery work.

In order to preserve the frequently handled books like achieves, books preserved in libraries for references, and old books of importance etc from getting damaged, such books are once again opened out, restitched and outer covers replaced with a firm leather or rexin case covers (wrapped) to preserve them for long run by this process. There are many types of binding techniques available and each type adapted for rebinding depends on the nature of the material required to be bound.

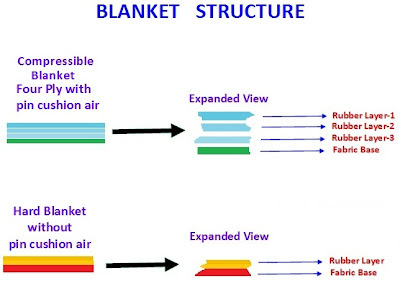

3. Blanket: A heavy rubber coated fabric material wrapped in one of the cylinders called blanket cylinder in the offset printing machine to transfer image on to the paper. The fabric-reinforced sheet of rubber is fastened to the blanket cylinder which receives inked image from the plate and then transfers it on to the paper. Various rubber materials are used for manufacturing the blankets which are of different qualities such as compressible blankets to hard finish with their surface having either smooth or slightly rough. While most of the printers prefer to use compressible type of blankets moderately rough blankets are also used by some of the printers. But the use depends on the type of machines they have as hard blankets have less contact with the paper surface thus reducing blanket contamination. Offset compressible blankets are constructed with two, three or four plies of a strong woven fabric fastened together with thin layers of rubber coating. The number of fabric layers equals the number of ply. For example two to four ply blankets would have two to four layers of rubber coated on them. To make the blanket compressible a thin uniform layer of air cells (for compression) is layered between the fabric and rubber face. The blankets should be free from pinholes, and blemishes lest it would affect print quality. The surface should also be non-abrasive to reduce plate wear. A good quality blanket will have the following qualities:

- Resilient: uniform surface hardness and hard enough to be capable of reproducing a facsimile of the printing image .

- Good Surface: very smooth or having a matte surface with no low spots or raised areas.

- Resistant: It should resist absorption of all kinds of ink, cleaning solvent and varnish used on the machine. But at the same time the blanket should be ink receptive failing which image transfer will be affected. The blankets should be resistant to peeling, blistering, embossing, de bossing, glazing or tackiness, and also abrasion from paper or board.

- Good Paper release: The blankets should be capable of giving good release of ink and paper from its surface as well.

As there are many types of blankets available it would be in the best interest of the printer to evaluate the right type of blanket that suits his machine work.

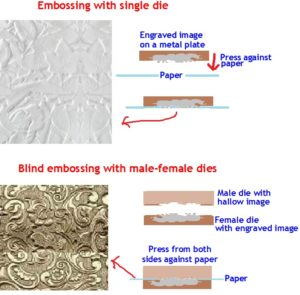

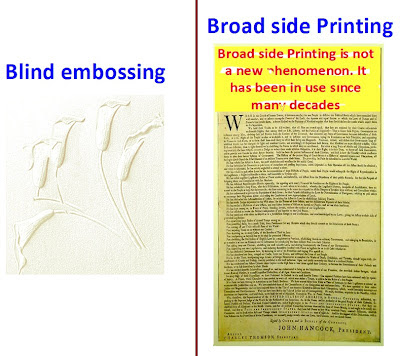

4. Blind Embossing: A finishing process in which a design is formed into a sheet using a die causing a slightly raised image on the surface of the paper. Normally in blind embossing no ink is used to form the image. (READ MORE DETAILS UNDER EMBOSSING.) The blind embossing is done both on plain as well as printed paper for giving different effects.

An embossed or stamped image is also done on the printed stock without applying ink or keeping foil. which is called Blind embossing. Blind embossing refers to giving embossed effect on certain portions of the image already printed on the paper. In such cases the image is first printed and to give a three dimensional relief effect to the image, the same image is given embossed (given relief) effect by pressing a male-female die in perfect register.

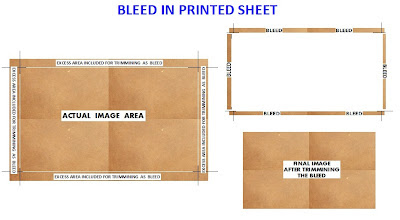

5. Bleed: Image that extend beyond the edges of the actual image required. When the printed sheets are finally trimmed to correct size, the images extended up to the edge of the sheet without showing even a hairline white margin around is derived. Therefore where printed images are needed up to the edges of the trimmed sheet without showing white margin, the extended image, beyond the actual required image called bleed, will be incorporated. Example: one can see the tints in the currency touching the edges without showing any white area.

Bleed allows us to print slightly oversize image than the actual image and when they are cut to exact size, seamless appearance of the image bleeding off the edges can be noticed.

6. Bond Paper: No special meaning be attributed to the word Bond in the Bond Paper. This term came into existence during first world war when ‘trade related mutual settlements’ called contracts or bond between two parties were written on hundred percent cotton rag paper, embedded with water marks to preserve them for long years. Slowly the business community too were inclined to use such durable paper for their correspondences, contracts etc which needed to be preserved for long time and accordingly got wood free bond paper made of partial rag content manufactured instead of full cotton rag content (to reduce the cost of paper) but with a watermark that showed the manufacturers name or their brands. Such papers were termed Bond Papers.

The Bond paper is superior quality of strong durable paper used for writing, printing and photocopying work. Bond paper is generally used for letter heads, paper used for communication and contract . The standard Bond paper is manufactured either with full rag content or with half rag pulp and manufactured in white or off-white shades. Since Bond paper is a high quality durable writing paper similar to the paper used on currency or bank notes they are manufactured having more than 50 gsm thick.

7. Brightness: This factor relates to the reflective quality or brilliance of the paper which affects contrast in printing processes. Paper brightness is defined by the percentage of light that it can reflect. Paper with a higher brightness allows colors to stand out, while lesser bright paper allows reading or meant for extended viewing. The brightness was introduced as a method to control the bleaching process during paper manufacturing. The brightness of the paper is measured by special apparatus reading on a scale of 0 to 100. Two standards are in vague – one known as GE standard read by a special instrument developed by TAPPI (Technical Association of the Pulp and Paper Industry), a research organization. While the TAPPI standard for the brightness is accepted by U.S , the ISO standard (International Organization for Standardization (ISO) is accepted by European, Asian and other countries.

GE brightness and ISO brightness measurements differ with each other due to different angle and the reflected source of light used in both the methods adapted by them. For example if the brightness on ISO standard is 100, the brightness reading by GE will be 98 and if it is 89 in ISO it will be 79 in GE and so on. If the brightness of the paper is very high it may sometimes alter the print result. The brighter and whiter the paper is, the brighter and lighter the images are. Colors on lesser bright papers are noticeably darker.

One important point that needs mention here is the confusion caused by Brightness and Whiteness which are two different properties of the paper constantly confused by the industry. While the brightness is volume of light reflected back by the paper surface, the whiteness refers to the shade of the paper.

8. Body color: The main text or design area of work except headlines.

9. Broadside: This term refers to the large sheet of paper printed only on one side, matter readable on the longer side. Examples are printed posters, public event proclamations, wall hanging pictures etc. This term is actually known as broadside printing. Broadsides have been one of the most preferred printed formats at one point of time for printing the public announcements, advertisement etc which had to be read from a distance, at the same time should remain eye catching. Therefore very large fonts are used for printing broadsides. Printed on single sheets of paper and on one side only, the broadsides show crudely printed look as very large fonts made of metal types could not be used for printing and engraved wooden fonts were used. The large metal fonts being heavy and not easy to handle caused working problem and therefore wooden type faces were prepared and used in their places. Hence crudeness in the printed fonts noticed on such printed stocks.

11. Bronzing: The golden effect on the printed image is produced by dusting bronze powder over the printed wet images. This is done to give effect of metallic finish which is otherwise done by foil embossing technique or use of metallic inks. The bronzing process is widely applicable to give effect of Gold printing which is used in the production of high-class labels, wrappers, box tops, covers, greeting cards and other work where bright, showy effects are demanded.

In this process the sheets are first printed with a tacky colorless ink, and then dusted with bronze powder which adheres to the printed image. Gold bronze powder is made from copper, brass and zinc alloy. Once the dusted bronze powder on the print gets dried, it is then lightly burnished to smoother and brighten the bronze and the loose left over bronze powder is cleaned off from the sheet. Small work can be bronzed by hand, but the work must be carried out under vacuum. Bronzing machines are also available for production of large quantities.

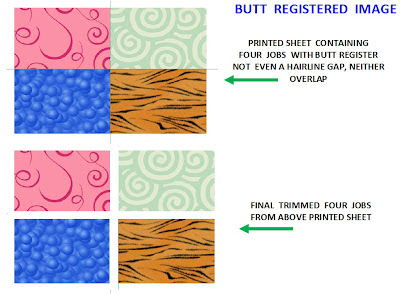

12. Butt Register : A technical term also called Kiss register where two images perfectly remain in register side by side or one above other without showing even a hairline break. In this printing process two different colored images sit side by side very closely, but they neither overlap nor a hairline space can be seen in between them. This term is actually extensively used in screen printing process.

13. Bursting Strength: This is another important factor that indicates the strength of the paper. The burst test is frequently used as a general guide to test the strength of paper, solid board and corrugated board. Bursting strength is usually quoted in kPa which is Kilopascal. Kilopascal is a metric unit and equals to 1000 force of Newton per square meter. While many countries indicate this factor as Psi which means Pounds per square inch, others express them in kPa both of which are tested with two different apparatus. But both Psi and kPa factors can be converted to Psi to kPa and vice verse by a simple conversion factor which is 1 kPa = 0.145037738 Psi. Be aware that the burst factor is inter related with tensile strength of the paper which is another factor that determines the strength of paper stocks. (The Tensile Strength can be read under Para Tensile Strength)

Recent Comments