Alphabet – D/3

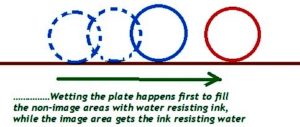

17. Dampening system : The dampening system is a vital unit in the wet offset machine. The wet offset process works on the principle that oil (ink) and water does not mix, and the images on the printing plates are in the same level of the plate surface, the dampening of the non image areas becomes vital to resist ink which should adhere only to the image areas. Every wet offset machine will have a dampening unit fitted on them along with the inking unit. Without dampening unit the wet offset can not function.

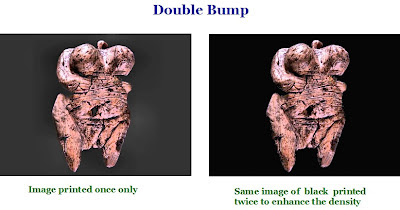

18. Double Bump : Some times in order to increase the density of printed image this process is adapted. By this technique the same plate is used to double print the image – mostly solids- thus the same image area get two layers of ink . This process is also called print on print process. This is done mostly on coated stocks and high value printing.

19. Dual Bond Paper : Strong inline coated bond paper suitable for printing by either offset or used on photo copier machines. This paper is mostly used for taking blue prints for architectural drawings, maps, and sketches.

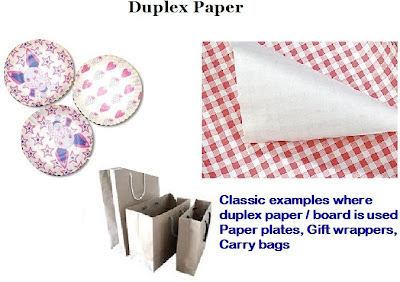

20. Duplex Paper : Thick paper made by pasting together two thinner sheets, or a thin sheet and HDPE film, or two thick boards. Each side of the paper will be different such as different color on each side, different finish on each side, or different textures. This variety of paper is used for producing retail Store printed bags, travel bags , paper plates, paper cups, gift wrappers, carry bags, gift bags etc. They come in various colors and textures.

Recent Comments