Alphabet -I/2

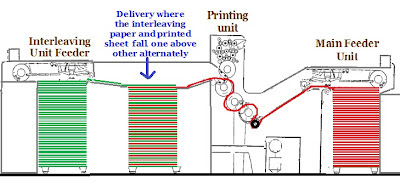

1. Interleaves or interleaving : Inserting a sheet in between two printed sheets is called interleaving. In the traditional printing, especially when the art paper or coated paper was printed, slightly absorbent papers called interleaving papers used to be inserted to prevent the ink from the surface of the previously printed sheet getting transferred on to the back side of the sheet which fall on top of the previously printed sheet. After the prints are allowed to remain static for few hours or one full day which is called the cooling period or drying time of the ink, the interleaved sheets are removed and the printed stock is processed further.

The interleaving is done on automatic presses by feeding the interleaving sheets from the delivery end of the machine by synchronizing the feeder with the main feeder from where the actual paper to be printed is fed. In short the Interleaving sheets are loose blank pages inserted between two printed sheets to prevent set off on the backsides of previously printed sheet.

2. Ink: Ink is a semi solid medium that is applied on to the printing plate or a block which in turn gets transferred on to the printable medium, to give visual characters to the images and texts. Though the term Ink is generalized and covers all types of inks like printers ink, fountain pen ink, ball point ink, ink for jet printing and so on, we are referring here as ink the oily ink used by the printers. Even in Printing ink there are many sub divisions like Letterpress ink, Wet and Dry Offset Inks, Silk Screen ink, Intaglio Ink, Gravure and Flexographic inks etc.

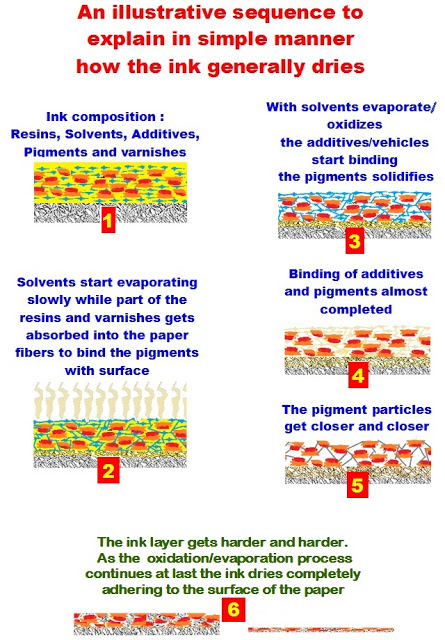

- Basically the inks for Letterpress and Wet and Dry Offset printing are slightly solid and contain four basic components such as Pigments which give colour, resins which bind the ink to the print medium, solvents to make the ink flow and additives to alter the physical properties of the ink to influence the drying of the ink on the printable medium after printing.

- The inks for Silkscreen process will be more liquid than the semi solid inks meant for above printing processes. The solvents used will be very different.

- The inks for Intaglio will be very stout much different than the ink used in above said processes.

- Gravure and Flexographic inks will be liquid almost like water.

3. Ink Drying : Inks are designed to dry by various means some of which are the following:

- Absorption by the medium

- Oxidation, when the oxygen in the atmosphere reacts with the ink and oxidizes the ink.

- Evaporation when the solvent in the ink quickly gets released from the components and allows the particles to solidify on the printed surface.

- Polymerization

- With special formulations, the ink is also made to dry by curing with UV light, hot air etc without getting their hues affected.

4. Inserts : Any loose print material which is inserted into the printed book which has been completed, is called an insert. The inserts will be normally found as loose sheet of paper like advertisements and informative material. Some times after a book is printed and bound, some corrections will become necessary and they can not be carried out again as the books has been bound. Therefore an insert called Addendum, or Erratum will be separately printed in a sheet which will be half the size of the book format and pasted at the last page of the book.

The advertising agencies and their clients utilize the opportunity to place promotional inserts of some products within the printed books, magazines and Newspapers. Such inserts may be form of any small picture, device, etc surrounded partly or completely by text matter.

Recent Comments