Alphabet – M/3

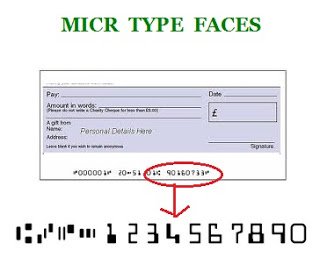

17. MICR and Magnetic ink : MICR denotes Magnetic Ink Character Recognition. The numerals printed by this technique is of special designs and character and are used by the banking industry to facilitate the processing of the cheques and other such documents which are printed as MICR.

The MICR , as defined by the American National Standards Institute (ANSI), is the common machine language specification for the paper-based payment transfer system and are printed with internationally accepted E-13B or CMC-7 Fonts for printing money transfer documents (cheques) . The characters in MICR are printed with a special ink called Magnetic inks which contain detectable magnetic particles something like iron oxides and are magnetized to enable them read with special equipment compatible to the magnetic ink and MICR character. The advantage of magnetic ink printing is that it allows the characters to be read at extremely high rates of speed and authenticate the document even if they have been overprinted or obscured by cancellation stamps and signatures.

Once the MICR characters are printed with the special type faces using magnetic ink they become readable by a special device which reads such characters. Every series of numbers are printed with a special symbol to begin with and another symbol at the end of the numerals. Actually the character alone is not read, it is read by the devices in combination with the magnetic particles embedded in the ink. In the machine that decodes the MICR text, it first magnetizes the characters in the plane of the paper and then pass on the same to the MICR read head which produce certain waves and transmit them to enable the system identify the waves to authenticate the characters printed.

18. Mail Order: Unlike purchase of products by visiting the stores or shops, the placement of orders for purchase by mail is called the mail order. Even the printing of visiting cards, procurement of greeting cards etc are done by placing mail orders.

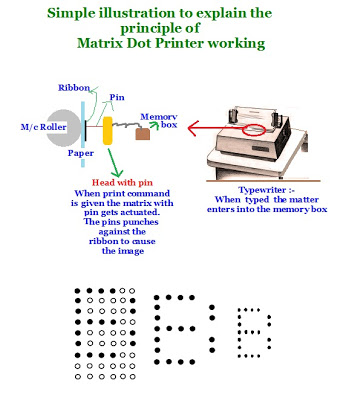

19. Matrix printer: This is also called Dot matrix or Impact Printer. Dot matrix printing represent the oldest printing technology used by offices, especially banking institutions where cost saving is considered to be important in respect of generating the receipts, invoices, reports and statement print outs where high quality resolution is not required. It is also widely used to print multipart forms and address labels.

The Matrix printer -mostly in the form of a typewriter machine has vertical row of tiny pins ranging from 9 pin to 24 pins to effect the print by hitting against an inked ribbon. As the head containing the pins move across the paper, the correct pins for a particular letter are pushed forward to hit the ribbons to form the image which is the letter. Each letter is represented by closely spaced dots. If the printed letter is enlarged and viewed one can see series of dots that has formed the letter. While the 9 pin dot matrix is commonly used for getting medium density print, to get better denser dot-patterns of high resolution and better print quality, then 24 pin matrix is used. Most dot-matrix printers offer different speeds depending on the quality of print desired. Several manufacturers have come out with various models of Matrix printers that can produce colour prints through a multi-color ribbon.

Compared to the laser and inkjet printers, the matrix printers are cheaper to work with, but the quality will certainly be not comparable to that of the laser or inkjet printer. However for multi page forms, which is set of carbon copies, while the dot matrix printer can do the job, the laser and inkjet printer can not give carbon copies, i.e in one go multiple copies.

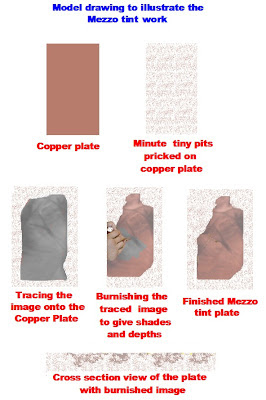

20. Mezzotint: Mezzotint is an intaglio printmaking process primarily developed for making portraits. The process involves the production of halftone type of images in line work with a copper plate.

- A copper plate is pricked by hand with a special tool to create innumerable tiny small pits which can hold inks.

- A image is transferred (traced ) on to the copper plate.The traced image is then created by selectively burnishing areas of the surface of the metal plate as per the shades of the image with special tools called burnisher which has smooth round edge.

- As per the image, shades of the image areas are burnished deeper or moderate depth with varying degrees of burnishing.

- Where the print is required to be blank, the dots are completely burnished.

The smoothed parts will print lighter than those areas not smoothed by the burnishing tool. This is a very laborious process but produces high degree of portraits and paintings. Before taking the print, the face of the plate is wiped clean, while the tiny pits in the plate holding the ink will be allowed to remain unaffected. This process is therefore very similar to Intaglio printing. A high level of quality and richness in the print can be achieved if it is properly done.

The mezzotint printmaking method was invented by the German amateur artist Ludwig von Siegen (1609–c 1680). His earliest mezzotint print dates to 1642 and was made by working from light to dark.

http://jimhubbman.calkinsc.com/mezzotint/mezzotint.htm

21. Micron: A unit of a measure for calculating the thickness. Its symbol is μm. The thicknesses of films and paper in printing are expressed in terms of micron measure. Minute distances, as, for example, the wavelengths of infrared radiation, are also given in micrometer measurements. One mille meter is (mm) is equal to 1000 micron. Therefore one micron works out to 0.001 mm. This is measured by an instrument called Micrometer. Various models of table top thickness measuring equipment are available in the market some of which show the measurement in digital display.

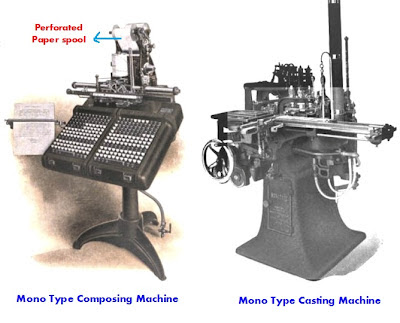

The Mono type was invented by Tolbert Lanston, who was born in the US in 1844. It consists of two units: a keyboard and a casting machine.

http://www.woodsidepress.com/MONOTYPE.HTML

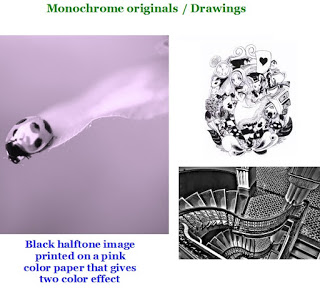

25. Monochrome : Mono means single color and therefore Monochrome original denotes an art work or design made of only with one colour, be it be black, Red or even Blue . Monochrome pictures are made in different shades of a single color. However multi colour effects are given by over printing the black and white or dark colour print of the monochrome original on a light shaded or colored paper to give effect of two colors. Even Duo-tone printing is sometimes viewed as Monochrome as the same single color original is printed twice without altering the original in any way, but printed in two colours with two plates, each plate made of the same image processed with two different angle of dots. That too gives effect of two color printing.

Recent Comments