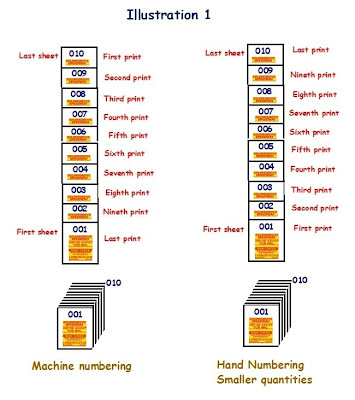

7. Numbering : The process of printing numerals on a print material by a set of boxes or a single box that contains numbering wheels is called numbering. Numbering is a wide term but in printing what is referred to as numbering is the printing of numbering on lottery tickets, currency notes, invoices, vouchers, bill books and variety of such print material where accounting is kept. The numbering is done both manually and using automated machines. Hand numbering is always done in ascending order since the quantity of such work may be limited. However where huge quantity is involved the numbering is always in descending order by automatic machines.

One of the important aspects that one should understand in numbering is the sequential numbering and random numbering both on individual sheets or in multiple up sheets. Sequential numbering is the process of printing numbers that begin with a given no and subsequently ends with the required end number.

For example when you start hand numbering for small quantity of jobs from 001 to 999 it goes on like 001, 002, 003 till the end number which is required to be produced is printed, say 999 such a process is achieved it called sequential numbering in ascending order (See the illustration -1).

Since the sequential numbers can be printed in either ascending or descending order the choice of printing in ascending or descending order will depend upon the quantity to be numbered. Where huge quantity of copies are needed such jobs will be numbered in automatic machines in the descending order i.e beginning with numbering the last number first, so that when the required number is printed and completed, the top of the printed sheet will show the starting no. (See the illustration -1).

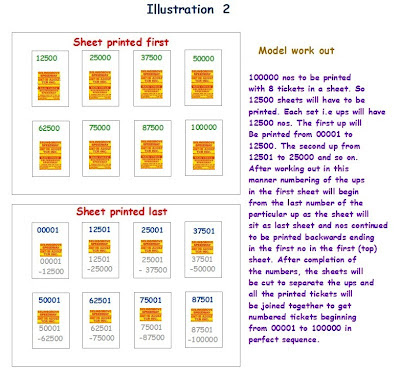

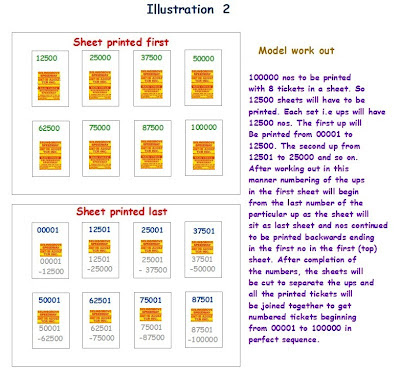

Another example of numbering huge stocks are numbering in multiple ups. Supposing one million lottery tickets are to be printed in one series, they will not be printed as one up format. The tickets will be printed in multiple ups most suitable to the sheet of paper used and then the numbering done in descending order (See the illustration-2 ) since printing individual ticket will consume not only more time but will also be not economical. Numbering Bank Notes too fall under this category.

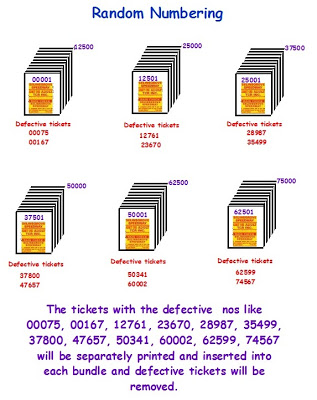

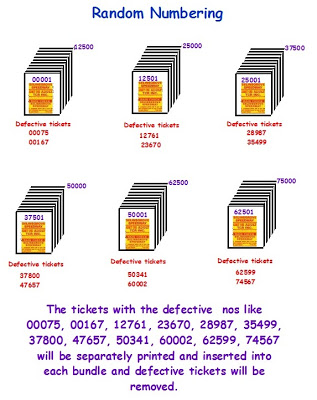

The random numbering is another process that is adapted in Bank Note or Currencies or Raffle ticket printing where the defective notes or tickets in a bundle is separately printed and defective notes/ tickets replaced. Supposing one million tickets have been printed in sequential no, and some have been found to be wrongly printed or found with damaged numbers, they have to be separately numbered and defective tickets replaced. Since they may belong to different bundles bearing different nos, numbering of such isolated prints can not be done as sequential numbering process and have to be numbered individually. The numbering of such print is called random numbering (See the illustration-3). For the random numbering single note numbering machines called Nota numbering machine or random numbering machines are also tailor made for the user industry and given by the firms of repute. Such machines are again not freely available in the market and are proprietary products of some of the firms. The single nos will be printed based on the input fed in the computer attached to those machines.

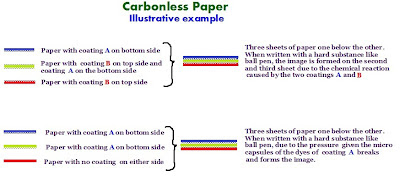

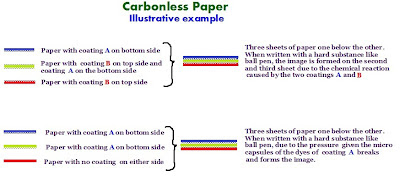

8. NCR Paper: The abbreviation for NCR is No Carbon Required paper, a brand name given for carbon less paper. The working principle of the carbon less paper is simple. The NCR papers are coated on the back and front sides with certain special chemicals. The micro-capsules of the chemical react with pressure of the pen and change its color in those areas pressed and form a color dye. Since the capsules are so small, the print obtained is very accurate. The NCR papers can be used on Dot matrix printers too, but can not be used on Laser printing machines. The NCR papers differ with other printing papers in respect of thickness. If the multiple copies are required in an invoice book, thicker paper can not be used and therefore the NCR are manufactured on thin varieties of paper below 40 gsm or so. (Also see Carbonless paper).

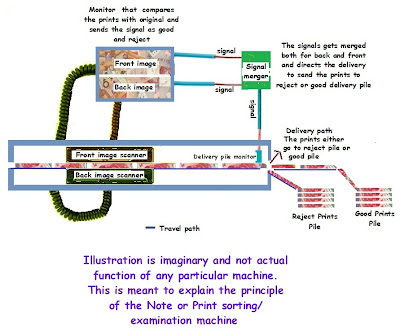

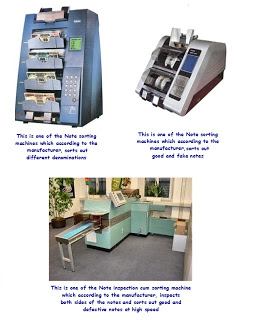

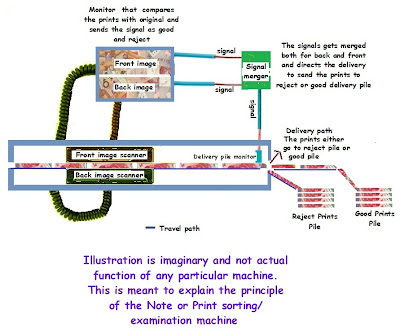

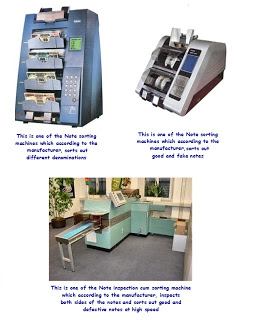

9. Note sorting or note inspection machine : These machines are used by the banking industries and the currency producing presses and Raffle ticket printing units to segregate the defective and counterfeit printed material. While the Banking institutions use these machines to segregate the spoiled, soiled and counterfeit notes, the Currency printing units and the Raffle ticket printing units use a bigger size machine of the same nature called inspection machines to inspect the sheets and separate them as sheets with defective prints by marking the defective prints with some visible mark so that they can be later random numbered and replaced or treat them as spoils. This process of note/ticket sorting is aimed as cost saving measure against manual labor.

The note sorting machine software will be programmed to suit the specific requirement of the banking institutions like segregating the genuine and fake notes, or segregate one specific group of notes and the other group of notes. (See illustration to understand the function). As for the Currency note printing units, and the Raffle ticket printing units, the software will have all the details of the notes or tickets including the security features hidden in them so that they will be compared with the master image stored to direct the machine to accordingly act in treating them as good or rejects. For Currency printing units and raffle ticket printing units the machines are custom made by specialist firms of repute and are not freely available elsewhere. Varieties of note sorting machines for banking institutions are however freely available in the market.

10. Non reproducing Blue: Certain colours can not be recorded easily by photographic means. One such color specially made is called Non reproducible light Blue called NRB. NRB does not record on graphic arts film, and therefore used to write instructions on layout sheets and originals, however at the sides without interfering with the work. Since NRB color and the white background are indistinguishable to photographic film, the NRB is not captured as an image by the film.

11. Nominal weight: The weight stated as the basis weight or the substance weight of the paper. The invoices are always raised on the basis weight of the paper and therefore tolerance of plus or minus 5% are always accepted in the industry.

See this example. Supposing order for 80 gsm thick paper is ordered, the paper mills can not ensure 100% thickness in all areas and therefore in some areas it may measure 80 gsm while in some areas they may measure 80.5 gsm or 79.5 gsm with minor variation in acceptable limits. However the nominal weight of the paper will be treated as 80 gsm only.

………..Additions to alphabet N to be continued under N/3

Recent Comments