17. Progressive Proofs: In multi color printing, prior to printing, as pre-press exercise, the colour proofs of each colour will be taken with the same color inks (as single up image ) which will be used in the final printing. The prints will be taken both separately and in combination (superimposed) with subsequent colors which will be overprinted to see whether the reproduced image reflected the correct color range as per the original. Once the correct color range is achieved matching with the original, they will be printed in the form of a folder called Progressive Proof and supplied to the printer to maintain the same shades during actual printing on the machine. Such a folder containing the single up prints of the multi color job undertaken is called the Progressive Proof or Progressive Proof Folder. This is done to aid the printers maintain correct color shade during actual printing.

A set of Progressive proof will normally contain the following:-

First page : Print from yellow plate alone

Second page: Print from Cyan plate alone

Third page: yellow plate print superimposed with blue plate print

Fourth page: Print from Magenta plate alone

Fifth page: Print from yellow plate print superimposed with blue plate print plus the Magenta plate print

Sixth page: Print from Black plate alone if black color is to be printed

Seventh page: Yellow plate print superimposed with blue plate print superimposed with Magenta plate print Plus the Black plate print

Eight page : the final print with all the four colors plates superimposed on each.

Sometimes instead of printing on the proof press, the color prints will be got done from the Inkjet printers. They are called Dry Proof, but serve the same purpose as Progressive Proof.

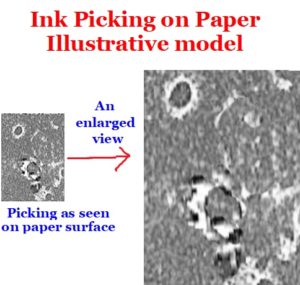

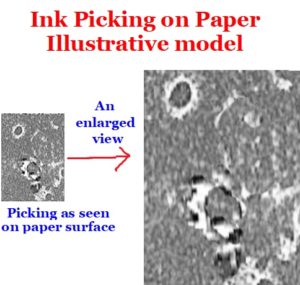

18. Picking : During printing one can sometime notice that the surface of the paper has been slightly lifted showing the area scratchy. This problem occurs due to the high tackiness of the ink which plucks away the paper fibers during image transfer. The reason basically is due to the use of ink which mismatched with the type of paper used in printing.

19. Prismatic Printing : This term is also called as Rainbow printing. Rainbow printing is a special printing technique where a background is printed in two or more colors from the same printing plate in single run. The effect is achieved by putting different shade of ink in the same duct from where the inks are supplied to the plate through the form rollers. Different shades of inks will be put in the same duct with a small divider that does not allow the inks to merge in the duct. But the different shades of inks flowing from the same duct will cause the rainbow effect due to the oscillation ink rollers which merge and blend the shades where they meet in the roller. (See illustration to understand this concept clearly) . This is considered to be one of the security Overt (Seen visually) feature in the art of security printing. The special varying effect is very difficult to reproduce by a scanner, computer or copier.

20. Penetrating inks: In order to impede forgery special printing inks have been developed as anti copy and anti counterfeit measures. In this direction, one of the inks that have been developed is called Penetrating inks. This term should not be confused with the ink drying properties which also mentions drying of inks by penetration. While penetration is an ink drying aspect, the Penetrating inks is special inks in the field of security Printing.

The Penetrating inks contain a special Red colored dye that penetrates into the paper surface to show trace of Redness on the back side. Another variety is that the Red strain is seen around the printed image. Both the type of inks are used in the numbering only and are patented products of few firms. If some one try to rub off the ink, the Red strain will show of the theft. Such Penetrating inks are mostly used for MICR numbering on Cheques and also on the numbering for Lottery tickets, Raffle tickets, Bank Bonds, Several Legal documents etc. The migration of inks serve as one of the security features to authenticate the documents by special gadgets which pick up the specific wavelength and authenticate the genuineness of the document. The penetration also depends on the substance used and therefore the ink maker will have to be told on which the authentication will be required so that suitable inks can be supplied.

21. Process Inks: Process ink means the transparent inks that are specially formulated for use in four color process printing or the four color inks used in Flexo, Gravure processes except Silk screen where the four colors are opaque in nature. The four color Process inks are Yellow, Magenta, Cyan, and Black shortly named as CMYK (K means black). While the four color inks are superimposed on top of the other to create the illusion of many more colors in Letterpress, Offset and Flexo processes, such effect can not be achieved by Silkscreen inks Intaglio inks as the process inks used in them are Opaque colors in nature.

………..Additions to alphabet P to be continued under P/5

Recent Comments