Alphabet S/ 6

When trimmed this will cause the margins of the inner pages become narrower than the outer edges. Therefore sufficient allowance has to be given during paste-up or stripping to compensate the problem of Creep. What is then the solution?

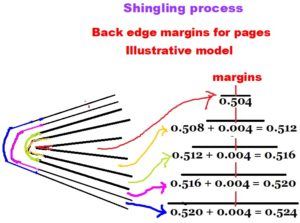

The solution to this problem is to keep progressive increase in the margins to compensate the loss of fold margin and to ultimately maintain the same margin in all the pages. If the progressive margin which is called the Shingling Process is not set properly then the final trimmed book will show few of the center pages front edge margins lesser than the back edge margins of the book. How is the work done?

There is no specific formula to carry out the Shingling process and to adjust the edge margins. But the most practical method is of the following:

– Make a dummy with actual size and no of pages and then trim it to correct size.

Leaving specified margin for the front edge margin of the book, drill two holes as shown in illustration touching the top and bottom edge of the running text matter inside.

Then leaving specified margin for the back edge margin of the book, drill two holes as shown in illustration touching the top and bottom edge of the running text matter ending inside.

Now when you open the pages and disassemble the paper dummy, you will see the exact amount of margins needed in each page to compensate for the creep. (See illustration-1 to understand this) .

The second method is as follows:

– Adapt the following calculation method worked out by many printers for printing such books

You have to carefully read the following to understand the work procedure. This is an illustrative example to guide you and to make you understand the implication of Creep solved by Shingling process .

1. Total pages of book to be printed: Say 90

2. Kind of binding : Saddle stitched at book spine.

3. Thickness of paper : Say 0.0020 in

4. Then the thickness of book will be : 90 pages x 0.002 = 0.09 inch*

5. Margin for each page at both the edges : ¼ inc

6. This thus makes the page margin between two pages to : ½ inch . When the sheet is folded to half, each page will have ¼ inch margin after stitching.

7. {*When the 90 pages book is folded into half it will effectively have only 45 sheets or pages ( 2 pages in each sheet, being front and back side print)}

8. Width of book : 8.5 inch

Since it is saddle stitch book, when the 90 pages book is folded to half, the inner sheets will remain projected like roof layer due to the thickness of the book. In such a case when the book is finally trimmed to 8.5 inches, the inner pages will not have ¼ margin in the front edges and also, the overall width of the inner page will be less than 8.5 inches (See illustration -2 to understand the reason).

Therefore in order to overcome this problem, the page layouts will have to be suitably modified for each page to ensure that entire pages will be 8.5 inch in width with ¼ inch margin in both front and back edges. How will it be rectified in the composed matter ? Let it be Letterpress printing using composed type fonts or for Offset Photo composed matter on negative. In both the cases the principle is same.

9. Normally the thickness of paper up to 5 pages will not alter the back or front margins considerably. Therefore every 6th page margin should be suitably adjusted to get uniform margin for all the pages.

10. So in this illustrative case the inner margin between two pages of every 5 th sheet is to be increased i.e ¼ inch + 0.002 inch {Total thickness of book 0.09÷45 sheets=0.002 inch per sheet for fold area}.

11. Based on above see how the adjustment of margin between two pages commencing from the center page is made.

– Back edge margin for Center Pages 41 to 45 and 46 to 50 = ¼ (0.25) + ¼ = ½ inch i.e 0.500 inch margin between two pages

– Back edge margin for Pages from 36 to 40 and 51 to 55 = ½ (0.5)+ 0.002 + 0.002 (for adjusting each side margin) = 0.504 inch between two pages.

– Back edge margin for Pages from 31 to 35 and 56 to 60 = 0.504 + 0.004 = 0.508

– Back edge margin for Pages from 26 to 30 and 61 to 65 = 0.508 + 0.004 = 0.512

– Back edge margin for Pages 21 to 25 and 66 to 70 = 0.512 + 0.004 = 0.516

– Back edge margin for Pages from 16 to 20 and 71 to 75 = 0.516 + 0.004 = 0.520

– Back edge margin for Pages from 11 to 15 and 76 to 80 = 0.520 + 0.004 = 0.524

– Back edge margin for Pages from 6 to 10 and 81 to 85 = 0.524 + 0.004 = 0.528

– Back edge margin for Pages from 01 to 05 and 86 to 90 = 0.528 + 0.004 = 0.532

The stripping of pages will be carrSpam (270)ied out keeping the space as stated above to compensate the fold and print if it is by Offset. If it is to be printed by Letterpress, the composed matter margins will be adjusted by inserting thin space metals as above.

One important point to be noted while cutting the sheets for printing on the machine is the following. Since the overall width of book will be 8.5 inches the size of cut sheets will be 8.5 +8.5 + 0.032 ( 0.532- 0.500 inch = 0.032 inch) i.e 17.032 inch or say 17.5 inches ( 0.032 to compensate the back margin, plus remaining 0.468 inch margin for trimming ).

When the entire sheets are printed and folded you can see the projection of inner pages by 0.500 inch which will get trimmed. When the book is saddle stitched and trimmed to 8.5 inch width, each page will have the margin of ¼ inch in front and back edges with 8.00 inch text matter occupying the pages.

Okay the Shingling Process for book making is understood. What about the sheets with multiple ups printed on heavy impression giving presses like Intaglio ? What sort of Shingling Process is adapted to compensate the paper stretch at the bottom? Again the same theory of progressive increase in margin is given between each rows, but the increase in margins between the center portion to the edges will be hairline compared to top edge margins. See the illustration to understand the increase in margins.

Recent Comments