The difference between commercial and Security printing

Though one refers the printing processes as Letterpress, Offset, Gravure, Intaglio, Screen printing, Flexo printing and latest as the Digital printing, the term Security printing process is not one amongst the independent printing processes, but it is an extension operating with some of the basic process from them.

Security printing is theoretically a congregation or combination of several printing techniques interlinked to protect the print on the essential documents produced for specific need especially for the use by Governmental agencies. Such documents include Currencies, Bank Notes, cheques, Passports, Certificates, ID cards, Stamp papers, university certificates, and Licenses etc.

On another side the same concept of Security printing has also been extended to the production of Brand protection covering labels of pharmaceutical products, automobile parts, life saving drugs, and many other such important documents which have higher face value in terms of product as well the price compared to normal products. Higher value does not reflect the aspect of cost alone, but even lower priced ones require protection against counterfeits to retain the specialized brand name prestigious to some of the firms in the midst of overwhelming percentage of goods counterfeited and that the counterfeiters are not diminishing.

In light of this background a significant section of the Graphic arts industry practices the art of Security printing. Protection of print through the process of Security printing has secure operational procedures and features to prevent a print being forged or counterfeited with same appearance along with their inherent qualities, and the forged ones remaining undetectable to public eye.

However even the Security printing practices have their own limitations in curbing the menace as the counterfeiters practice the art of counterfeiting with more impunity using relatively low cost technology that includes digital computers, color copying machines, and image scanners. Thus, it has become extremely important for Security printers to remain ahead of counterfeiters and forgers by using the latest security features and aspects.

How different is the Security Printing compared to conventional art of printing? How are the prints on documents protected ?

If you need an answer first one will have to understand the basic process involved in the conventional and the Security Printing techniques before understanding deeper concept of Security Printing.

In conventional printing process the first stage is to convert the multi tone originals into several printable plates or blocks to reproduce multi colour original effect on print. This is achieved by super imposing primary colours, one colour above the other by the technique called colour separate and then print. At least four basic colour separated plates/ blocks are required to print in individual color components like cyan, magenta, yellow and black colours to match the original.

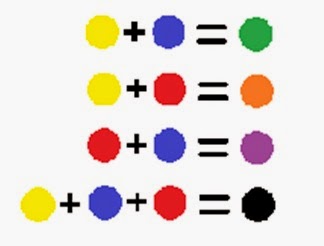

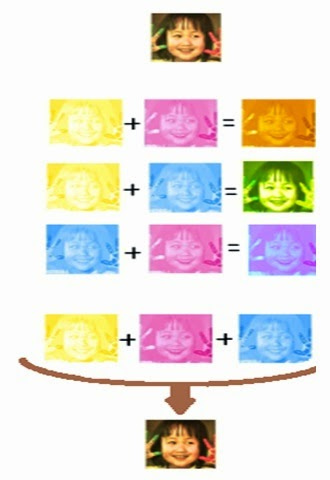

The coloured original may comprise of many shades and the shades too in different hues and tones. For example the shades may be bluish green, darkish green, pinkish, pure blue, pure yellow or pure Red while several other shades have merged with them. Let them be any shade or colour, always remember that they fall within the range of Rainbow spectrum of colours only. Thus the effect of any shade is as closely as possible archived on print by reproducing them with three to four plates using primary colour inks. This means the primary colours produce secondary and tertiary colours by different tonal values of the primary colours. Say yellow plus blue gives green. Blue plus Red gives Violet. Red plus yellow gives orange and yellow plus Red plus Blue may give black etc. The conversion process, i.e original to printable image format, is carried out to prepare a basic material for making the plates/blocks. The basic material is photographic films called halftone and continuous tone negatives or positives through a process camera or a scanner. Generally in the conventional processing technique a set of four halftone negatives/positives are prepared using colour filters and halftone screens to print yellow, cyan, magenta and black colours on paper to render the true colour image as per original copy – all processed manually. However with latest developments even direct to plate equipments supply colour separated plates/blocks replacing the manual processing photographic techniques.

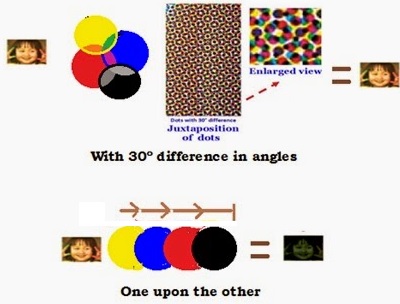

Once the colour separated halftone negatives/positives are prepared, so many plates and blocks are prepared and each plate or block is printed with four basic coloured inks such as cyan, magenta, yellow and black, known as CMYK. While registering the images on the substrate on which they are printed the dots in each plate sit in an angle of 15 to 30 degree from each which in technical term is called juxtaposition of dots and give the desired colour effect as close as possible on print.

Unless halftone screens are used, the continuous tone shades in the photos cannot be converted into printable form. And unless the screens are positioned in a particular screen angle with a difference of 30° for each colour separated negative or positive, the juxtaposition of dots i.e. printed side by side cannot be achieved and all dots will fall one upon other to give one single colour image. Again the resultant image will be one dark image.

This is the basic structure of processing in the conventional printing process, whether it is Letterpress, Offset or Gravure.

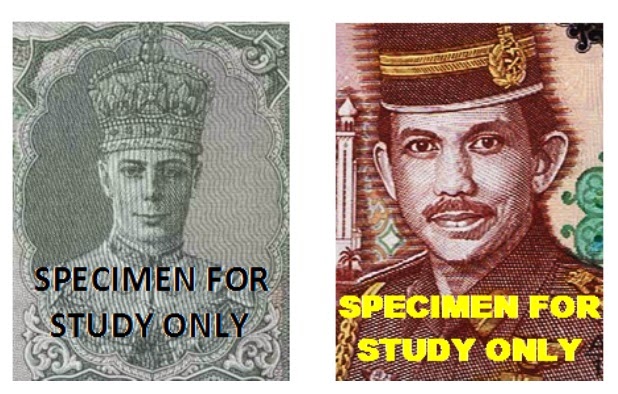

The basic processing is the main deviation in the case of Security printing compared to the conventional printing. Security printing technique is devoid of colour separated, halftone screened negatives or positives to reproduce the original colour print. Further the primary colour inks like Yellow, Magenta and Cyan are also not used to print juxtaposition of dots to reproduce the coloured original. No screens or colour filters are used for colour separation. In short, basically the Security printing is reproduction of the coloured original in true form incorporating lines and other patterns of varying sizes and thicknesses on the plates or blocks sans juxtaposition of dots on print.

The photographs or portraits are first converted into elements consisting of minute dots and lines of varying thicknesses, wavy patterns, Guilloche designs and several types of straight lines and with micro letters in between.

The artist converts the continuous tone photographic image or portraits into various tonal values with lines, dots and other patterns by hand engraving them on metal blocks which is used as base for further processing. The separately engraved blocks with shades are finally joined together to form the printable image as close as possible to the original. Now automatic processing equipments and machineries have also come to convert the continuous tone images of the original to the desired pattern printable as line work.

Since the colour original is not colour separated into three or four colour negatives or positives using colour filters and screens they remain difficult to colour copy or counterfeit. If the security printed print is copied, the lines will be converted into several minute pixels instead of continuous lines or wavy lines due to use of different angles in the engraved elements and therefore the forged one will not match with the original design elements. To naked eye it may appear to be near original, but even with a small magnifier the print will reveal it to be counterfeited.

How are the colour effects arrived on the reproduced prints then ? The various colour effects are not derived by super imposing the images one on top of the other using conventional shades like Yellow, Blue and Red. The relief images from Dry Offset plates or images from plane plates of Wet Offset are printed in subdued colour combinations through a process called Rainbow printing in which the colours merge in a varying, uneven manner creating a spectrum of colour effect. This again makes the copying difficult to reproduce by colour copying or scanning.

How the images on print gets further protection from forgery or counterfeiting is by the use of several elements in combination like overt and covert features such as layers of colour elements printed one on top of other, intricate designs, special inks, the tactile feel of inks and completely different printing techniques deployed. Generally three levels provide security on the print. Level one may be by overt features, such as optical variable ink and watermarks, security threads etc identifiable by naked eye. Level two may include the covert features which may require certain gadgets or instruments like a microscope, enlargers, UV lights, Infra Red lights etc to authenticate the features. Level three may be most complex, involvement of certain chemicals such as markers or taggants mixed with printing ink which can be authenticated only by specially designed user specific Gadgets to read the material as supplied by the same manufacturers who supply the taggants or by specially trained forensic agencies and chemical labs.

The machineries and equipments used in the production of the security documents employ only the same basic machineries and equipments used in conventional printing, but the difference is that they are modified ones to transfer the images with special inks, intricate processes with special attachments. Prima facie the Security Printing too is only an extended arm of conventional Offset, Letterpress and Gravure printing techniques, but deployed in modified manner through modified machineries and equipments.

The background designs in security printing consist of intricate lines and patterns that do not copy or scan well. Since they are generally printed in lighter colours, designs in several areas disappear when scanning is attempted. The design elements such as Guilloche patterns, invisible image, Ghost images, E-Beam image etc are produced with very special inks. The micro letters printed are so small (about 1/100″) that it may appear as a solid line and if photocopied or scanned the letters will becomes a solid line. The Ghost images are also invisible on print and appear only when viewed in one or two directions. Therefore if scanned or attempted to colour copy the images is resorted the designs will break into pixels instead of lines or dots as per original.

Even conventional Wet offset and Dry offset machines are used as one part of security printing to print base elements over which the other design elements are placed using Colour changing inks, Thermo inks, Solvent sensitive inks, OVI, Magnetic inks, Bio-metric inks, Fugitive inks, invisible inks, Taggants Coin reactive inks, Bleeding inks, UV Invisible Fluorescent Inks, Erasable inks, OVI, Penetrating inks, Magnetic inks, Thermo chromic inks, Infra Red inks, Fluorescent inks, Magnetic inks, Chemical reacting inks etc through user specific machines specially manufactured for use by them with special attachments.

Generally the dotted designs are avoided as they can be easily copied. Since the colour original is not colour separated into three or four colour negatives or positives using colour filters and screens for Security printing they remain difficult to colour copy or counterfeit.

Another major aspect in Security printing is the use of special substances on which the prints are taken. While in conventional printing process, various kinds of paper substances and substrates including plastic foils available in the market is used, in Security printing only specific and specially manufactured substrates and Paper bases are used which are end user specific material made to order and not available elsewhere in the market except with the manufacturer who will also be not supplying them to any other user.

The others elements that add up security on the prints are OVD patches,Holograms, Hot stamping, use of specific instrument detectable Taggants in ink, highly sensitive water marks, product specific printing concepts like PEAK and STEP etc and many other such products available with the manufacturers of security processes which are extremely difficult to copy for counterfeiting. The special effect and type of numbering is another important aspect in Security printing whose numbering boxes are not supplied by general numbering machine manufacturers. They are country specific or user specific made to order and numbering on the wheels that print them are engraved manually, not available in market.

In short the security printing processes has a fleet of specialized machineries and equipments as though they are made for each other. They include end to end usable process in which the entire sheets printed are cut to specific sizes, contain specific no of pieces per bundle, strapped, polythene wrapped, shrink packed and labelled all in one process, one machine, entire operations automatically carried without manual intervention.

The reproduction of the above security documents are carried out by specialized machineries and equipments as below:

Dry Offset Printing: The process involve use of plates having the images to be printed in relief format. The machine prints on both sides of the completely room conditioned paper/substance in one pass in perfect register. The most difficult registration process involved in this is see through register in which a complete image is split into two parts, and each part is placed on each side of the sheet. When they pass through the printing machine the images fall exactly in same position on both sides in one pass and when the sheet is viewed against light, you can see the complete image in perfect registration.

The second most important aspect involved in this process of printing is rainbow pattern of printing- several shades side by side, one after the other in which subdued colours are used. The colours merge and show the image in series of shades.

Intaglio printing: The substance on which the image is printed takes almost few tons of pressure on them and show raised image on the surface which can be felt by the touch of finger. The images on the plate will be sunken and uses specialized hard ink which when dry gives relief.

Inspection of printed sheets before numbering: The entire sheets printed by Dry Offset and Intaglio are manually inspected to sort out the all good sheets and sheets with defects.

Numbering: Several numbering boxes are fitted on this rotary machine which numbers the sheets in the pattern set. The sheets are numbered either in continuous numbering pattern or part numbering of all good prints.

Cutting and packing: The numbered sheets are again checked to mark defective sheets and processed on automatic cutting cum packing machines in which the entire sheets printed are cut to specific sizes, contain specified no of pieces per bundle, strapped, polythene wrapped, shrink packed and labelled all in one process, one machine, entire operations automatically carried without manual intervention.

Recent Comments