Effects of altering sequences of printing

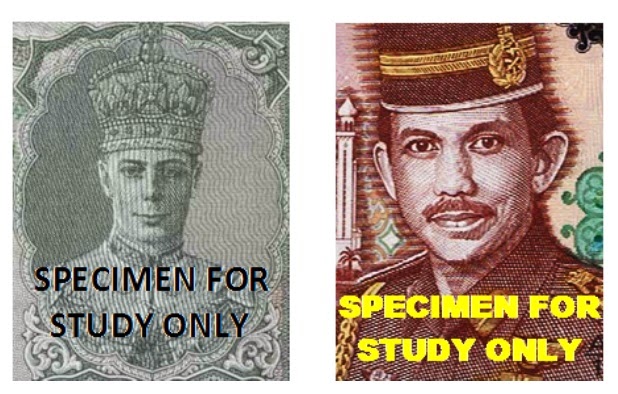

Similarly in the Security Printing process, where the design elements are of intricate design elements likes various thickness of lines, wavy patterns, Guillosche designs etc for example the currencies, cheques, stamp papers, and labels with hidden security features, certain sequence of colour printing is followed with separate plates after the proof is approved with the same sequence. The colour sequence will not be however Cyan, Magenta, Yellow and Black as in conventional printing process, but each plate will have a rainbow of colours of entirely different hues and shades in different band widths. Since the primary colours are not used, the question of forming secondary and tertiary colours also does not arise as the shades will be entirely different in nature and the design elements criss–cross over the other to give visual shade. The colour separated plates does not have halftone dots in specific angle and not

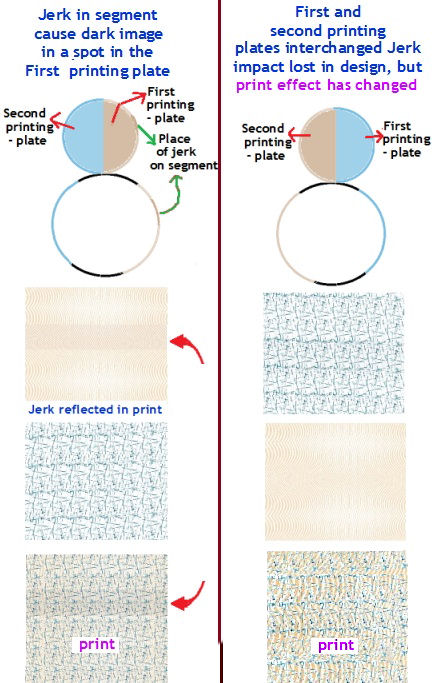

printed on top of each other with Cyan, Magenta, Yellow and Black in order. This is the fundamental difference between the conventional printing process and the Security Printing process.Against this background one need to understand what governs the principle of the sequence of printing the colours. How important is to follow the sequence of colours in both the processes of printing and what will happen if they are changed ? It may so happen at times that in order to save idle hours w

henever some technical problem or the other lead to the temporary stoppage of the machines either for change of a specific colour plate, or get modified ink for smooth flow on the machine, all of which may take quite some time to arrive, some alternate actions may be taken by the printers to keep the printing continue.

Universally certain standards have been laid out for reproducing the multi colour originals in certain colour sequence since the sequence of printing plays a vital role in determining the quality (appearance) of printed color reproductions even though few other factors too influence the quality of reproduction such as the transparency and the tack of the ink.

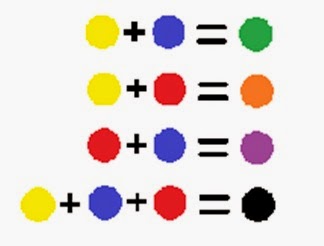

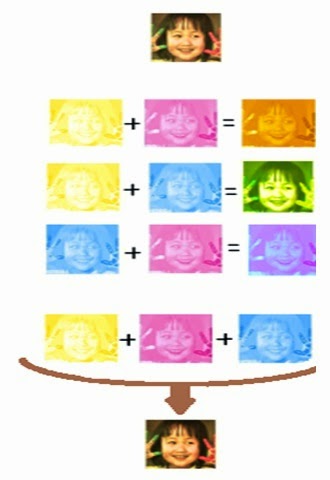

Theoretically speaking, colour image is reproduced by two types of Colour models namely additive and subtractive. They are technically termed as RGB meaning additive colour with Red, Green and Blue lights while the second one is called CMYK, which is subtractive color with Cyan, Magenta, Yellow and Black using printing inks.

In the case of RGB sequence red, green and blue light are added together in various combinations to reproduce a wide spectrum of colours for the display of images in digital photography and web designs on computers. In respect of printed reproductions on paper or any other surface using coloured inks, the accepted norm for the printing sequence is Cyan, Magenta, Yellow and then Black, shortly termed in technical language as CMYK sequence if it is four colour process of printing, or CMY if three colour process of printing.

The CMYK is a subtractive color model, used in multi color printing on printing machines using semi solid wet inks. The printed ink reduces the light that would otherwise be reflected. That’s why this model is called subtractive because inks subtract the brightness reflected from a white background from the colours printed. Some presses even resort to printing in YCM order.

The coloured original may comprise of many shades and the shades too in different hues and tones. For example the shades may be bluish green, darkish green, pinkish, pure blue, pure yellow or pure Red while several other shades have merged with them. Let them be any shade or colour, always remember that they fall within the range of Rainbow spectrum of colours only. Thus the effect of any shade is as closely as possible archived on print by printing them with three to four primary colour inks. This means the primary colours produce secondary and tertiary colours by different tonal values of the primary colours. Say yellow plus blue gives green. Blue plus Red gives Violet. Red plus yellow gives orange and yellow plus Red plus Blue may give black etc.

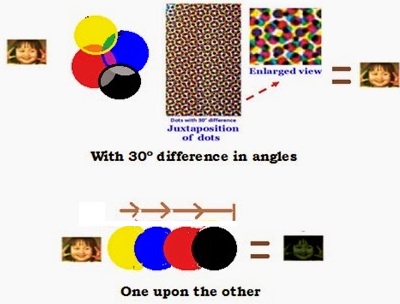

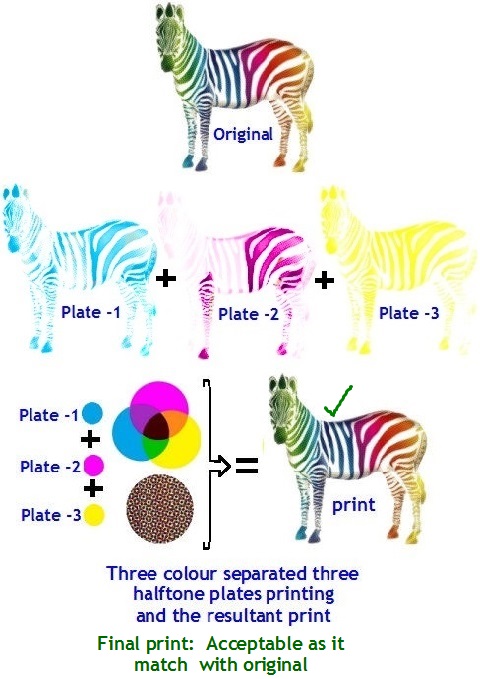

The plates for printing are prepared with a set of four colour separated halftone negatives/positives using colour filters and halftone screens to print yellow, cyan, magenta and black colours on paper to render the true colour image as per original copy. Once the colour separated halftone negatives/positives are prepared, so many plates and blocks are prepared and each plate or block is printed with four basic coloured inks such as cyan, magenta, yellow and black, known as CMYK. While registering the images on the substrate on which they are printed the dots in each plate sit in an angle of 15 to 30 degree from each which in technical term is called juxtaposition of dots and gives the desired colour effect as close as possible on print.

Unless halftone screens are used, the continuous tone shades in the photos cannot be converted into printable form. And unless the screens are positioned in a particular screen angle with a difference of 30° for each colour separated negative or positive, the juxtaposition of dots i.e. printed side by side cannot be achieved and if all dots fall one upon other, it will then become a single colour dark image.

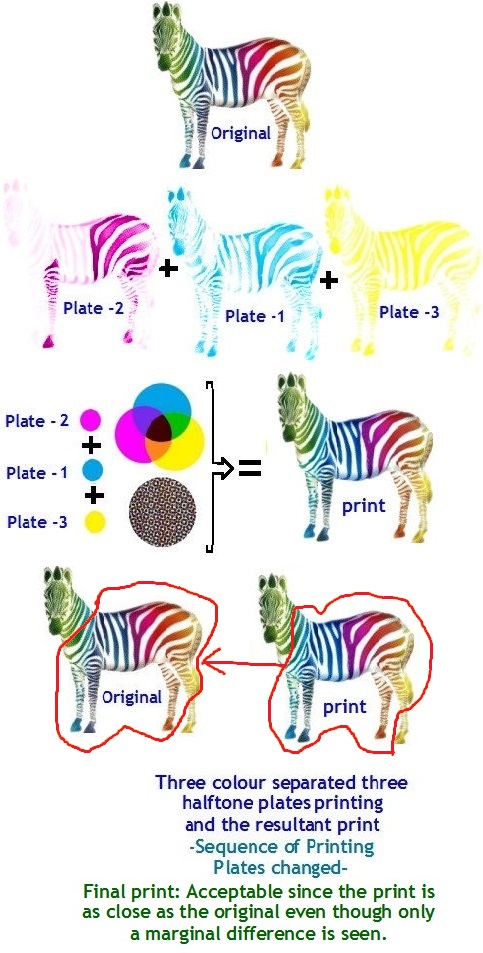

This is the basic structure of processing in the conventional printing process, whether it is Letterpress, Offset or Gravure. What will happen if the sequence of printing is changed from the accepted norms of CMYK into CYMK or YCMK ?

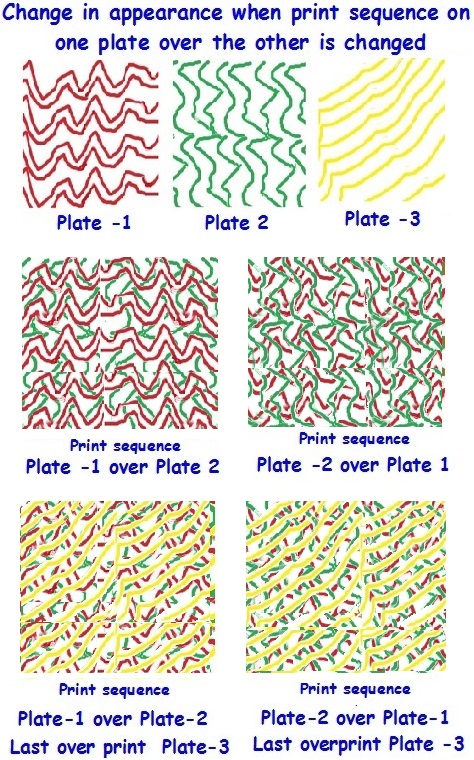

Not much difference in the appearance of the ultimate print will result in. Even if there is small change, it can still be brought to the original shade by slight adjustment of the ink shades since the dots fall in juxtaposition leaving the other elements fall in their own position. See the following illustrations to understand the effect of following and deviating from the sequence of printing.

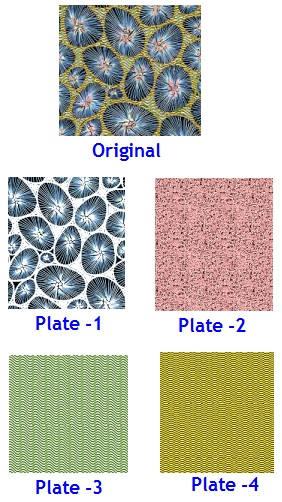

Security printing process:-

The artist converts the continuous tone photographic image or portraits into various tonal values with lines, dots and other patterns by hand engraving them on metal blocks which is used as base for further processing. The separately engraved blocks with shades are finally joined together to form the printable image as close as possible to the original.

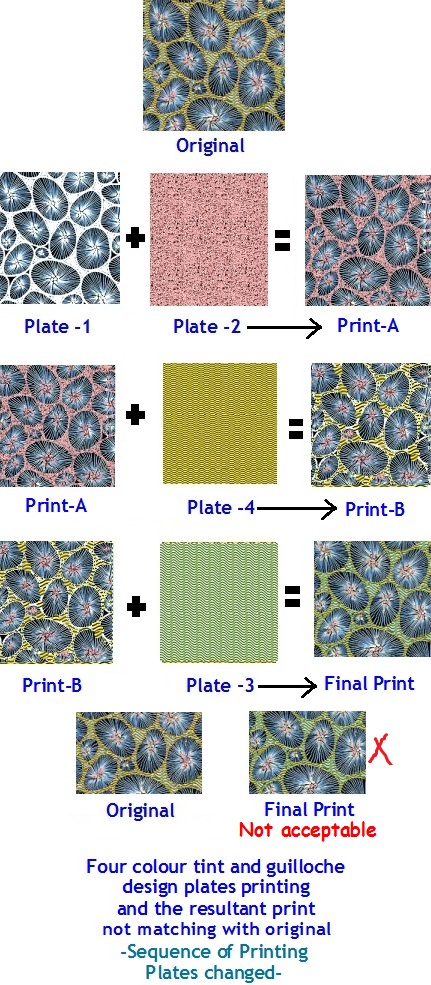

Certainly the

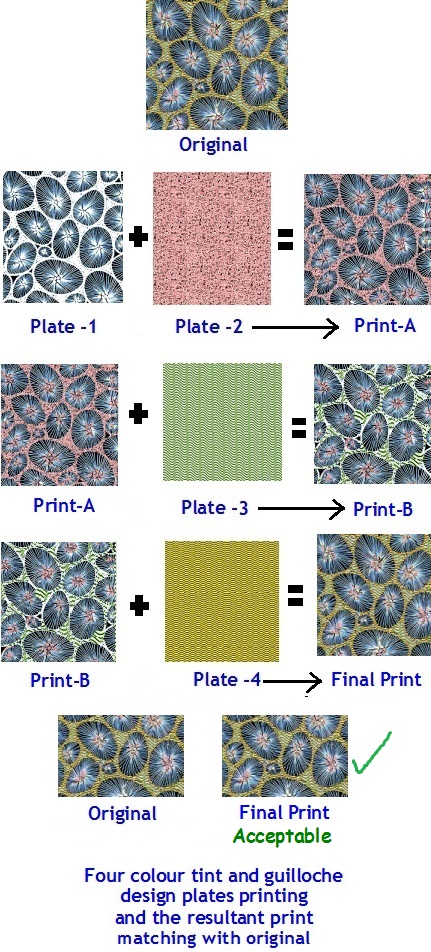

appearance of the ultimate print will show a different result and will not match with the approved proof. Reason ? There are no fixed tertiary or secondary colours emerging from the combination to cause different hues within CMYK. The colour effects will be much different as the inks are of semi translucent in nature.The most important aspect is that the different hues appearing all over the body of the print are all independent shades or colours, some of which are so subdued that there is no scope to show a third colour glaringly. The wavy lines and straight lines which are positioned in different angles in the design itself gives different hues to naked eye even though the shades may be same. The lines are not in juxtaposition and instead fall on one another crisscrossing in rainbow of independent shades. The shades of the lines that fall on top of the base design elements dominate in visual appearance. Thus altering the sequence of printing after the proof is approved with certain sequence of rainbow colours matching to the image will show different hue on the print. the See the following illustrations to understand the position.

sequence of Rainbow colour

Appearance of Print by interchanging the

sequence of Rainbow colour

Recent Comments