Guide to printing students – 8 a

Written by : N.R. Jayaraman

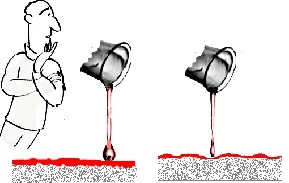

37) What is see through printing ?

This is a special technique employed in high security printing like printing of Currency notes and possible only on perfecting presses where the recto verso sides of the paper is printed simultaneously in one pass. The floral design to be printed will be split into two halves and each halve printed on either side of the paper in such a position that when the sheet is held against light, the two halves of the images will show as a complete image in perfect register without disjoint. This is known as see through printing.

38) What is tear resistance ?

While the Tensile strength is meant to determine the point at which the paper will crack or burst, the Tear resistance is another important property for paper that is taken into account while manufacturing of bond papers, cover papers and wrapping papers. Tearing resistance indicates the ability of the paper to withstand tearing force when it is subjected to. When a paper gets torn at the edges, how fast it can be torn in either directions will determine the tear resistance. The test will demonstrate whether the paper will get easily torn or strong enough to withstand the wear and tear during various usages. If the paper gets easily torn (once the edge starts tearing) then it can be considered to be a weak paper. Therefore the paper is subjected to tear resistance test in both ways i.e Machine direction and Cross direction and average worked out to express the tear count in Mille Newton i.e mN. The fiber in the paper determines the strength and therefore fibers floating in the machine direction will be more stronger, at the same time more suitable to use on jobs where creasing or scoring operations in addition to folding operations are involved. However for wrappers, covers and other such usages like packaging papers, the paper needs to be stronger in both ways. in order to ensure that the paper remains stronger in both ways, the pulp travel path wire is shaken in regular intervals to ensure that the fiber float direction is made both vertical and horizontal. One of the most commonly used instrument to measure the tear test is the Elmendorf Tear Tester which measures the force perpendicular to the plane of the paper required to tear multiple plies through a specified distance after the tear has been started. All the tests are carried out in specified conditions with specified size of samples. Four ply (Four sheets one under the other) test samples are clamped to the clamper provided on the machine and with the integral knife handle fitted on the same machine the initial cut is performed. Since the machine is pre programmed, the extent to which the initial cut is to be made etc will be uniform. Then the pendulum will be released to perform the tearing. Then the readings of both the force required for initial cut and the tear with pendulum apparatus will be computed and result obtained.

39) What is tensile strength ?

40) What is bar code printing?

A bar code is an optical machine readable representation of data relating to the object to which it is attached. Originally bar codes represented data by varying the widths and spacing of parallel lines. Each firm can generate their own coded bars. See illustration below for example which shows different line widths and space for some of the numerals. Ex 2, 3, 0 etc . The bar code generator allows you to create a bar code graphic by providing bar code data, encoding type, and output file format. Bar codes are made up of a series of narrow and wide bars that can be scanned using a photo-type of sensor. This sensor reads the bar code, turns it into a signal which is then sent to a computer or network. This scanning method calculates the measurements between each bar and space and translates those measurements into characters. Each pattern of bars in the code is represented by a character. All bar codes commence with a unique start character and concludes with a unique stop character. By having the bar code laid out like that, the scanning equipment can determine which way the code is scanned in, whether forwards or backward. There is also a fail safe entered into the bar code and it is called a checksum character. This character is inserted right before the stop character in the bar code. This checksum is tabulated from the other characters in the bar code and if the scanning equipment does not match the checksum during a scanning session, this is a signal that something is wrong.

Recent Comments