Guide to printing students – 23

-Few objective Questions and answers-

Written by : N.R. Jayaraman

103) What is 2D and 3D printing?

2D printing is a regular laser or table top printing process printable on flat sheet of paper or any other similar paper based material using powdered toner or some kind of ink.

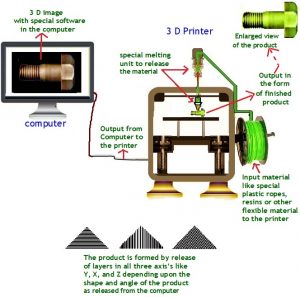

The 3D printer is miniature model creating machine which create 3D objects from 3D images with the help of specialized CAD software. Though basically it is not a printer by itself, since it works on the principle of a printer by creating the objects, layer by layer through spraying or dropping micron size input material through a small needle spaced nozzle as fitted on a printer to convert the images into objects, it is called 3D printer. Charles Hull is the inventor of stereo lithography, the first prototype technology commonly known as 3D printing.

104) What is the functional difference between 2D and 3D printing?

The images and texts, either black and white or in multi colours are scanned or created otherwise on the computers and printed on a flat surface such as a sheet of paper or any other similar substance by regular laser printer through jet nozzles is called 2D printing. It can print only two axis like length and breadth in the printed image formed. Some kind of ink liquid or dry or powdered toner is required to print the images stored on the computer on to a surface of the paper or similar substance in surface.

The 3D printing is meant for an entirely different usage and not a actual process of printing. Actually the name cause confusion indicating it to be a printing process while it is not. The earliest intent of 3D printing was for research and development purposes and machine tool rooms to create prototypes or samples of the objects in smaller sizes for further testing the components for commercial use. Later developments saw the production of the materials (objects) in bigger sizes based on the computerized image created containing accurate dimensions of the models to be created in material form through a specialized CAD software in a computer.

3D printing process works which with a special CAD software to create the object in the layer by layer manufacturing process. The material instead of ink toner is released as micron size particles in all three axis (length, breath and depth) through a nozzle similar to the one in the desktop printer which release the toner. This is the reason why it is called 3D printer because no toner or ink of any kind is used in 3D printing machine to get the output and instead materials like metal, sand, concrete etc or plastics are used to build the specimen by ejecting micron size particles in the layer by layer manufacturing process. Because the process involve depositing the raw materials layer by layer in all the three dimensions, it is called layering process or layering technique.

The material is created by depositing layer by layer material in all three axis –X, Y and Z- in the same angle, size and shape, between 16 to 180 microns or more to create the 3D models based on the input from the 3D image stored in the computer. For creating the object, one has to first create the image needed for 3D printing either by scanning the original product with CAD software or created with the aid of engineering drawings showing perfect dimensions of the end product. The image is then converted into the 3D model to Standard Tessellation Language called STL format, and then data fed into the 3D printer software for suitable conversion to build file for printing by a 3D printer. Once the 3D image of the original to be reproduced is created, then the material with which it is to be created is decided and the relevant 3D printer machine engaged for reproducing the model. The process is explained in brief below in the form of an illustration:

Recent Comments