Guide to printing students – 30

-Few objective Questions and answers-

Written by : N.R. Jayaraman

119) What parameters are important in the Paper used for printing?

The general parameters which are important for printing paper is:-

- Basic weight

- Thickness

- Opacity

- Bursting strength

- Tear resistance (Tensile strength)

- Porosity

- Folding endurance

- Air permissibility and finally

- Absorbency

- And in some cases like currency papers it is L*A*B*

120) Explain in brief how the properties are important in paper.

Basic weight:

The cost of the paper is determined by its weight. Also the suitability of paper for specific job is determined by its basic weight which is expressed in terms of GSM. The value of GSM is represented as so and so many Grams Per Square inch of the paper based on which the weight per 500 sheet of specific size paper is calculated to fix the rate per 500 sheets (ream). For ordinary jobs, generally 80 to 82 GSM +/- 2 paper is used while for specialized jobs like pamphlets, brochures, ledgers, account books etc higher GSM paper is used.

Thickness:

The thickness of the paper is interlinked with GSM and the thickness is measured by a micrometre, expressed in terms of micron, the symbol being μm. This is an important factor in printing as the uniformity of thickness is essential to produce a good image and proper feeding from feed board since the double sheet detector will malfunction when non uniform thickness of paper is fed. The paper thickness also influences the optical density, opacity, and paper strength etc.

Opacity:-

Opacity in simple term is the ability of the paper to obstruct passage of light. This factor is influenced by the basic raw material like cotton rags or wooden chip fibers along with chemicals called filler which form the paper and in turn influence the thickness. If the paper has insufficient opacity, then traces of printed texts on one side will appear on the back side and mar the appearance.

Bursting Strength:

This is an important factor that indicates the strength of the paper especially meant for converter and packaging papers. The degree to which the paper can withstand pressure without rupturing is represented by this factor. The use of fillers, their quality and quantity determines the bursting strength. While increased use of filler decreases the bursting strength, the increased use of longer fibers and surface sizing increases bursting strength. The burst test is meant to test the strength of paper, solid board and corrugated board. Also this factor is interlinked with tensile strength, which is another factor that influences the strength of the paper against rupture. The bursting strength is indicated as kPa which is Kilopascal. Kilopascal is metric unit and equals to 1000 force of Newton per square meter.

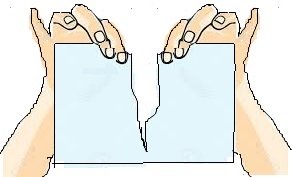

Tensile strength (Tear Resistance):

This factor which is physical property is to indicate the ability of paper to resist tearing. The Tensile strength influenced by the fibre orientation indicates the extent to which the paper can be stretched without breaking. Since the fiber orientation is dissimilar between machine direction (MD) and cross direction (CD), the tensile strength is measured in both directions. Machine direction is the direction of the paper web which is running on the machine, while the Cross direction is perpendicular to the paper sheet running on the machine in paper making process. It is greater in machine direction than in cross direction The Paper is generally stronger in machine direction compared to cross direction. This factor is more important in papers meant for packaging, wrapping and papers used on web printing machines. If the tensile strength of paper is lower, then the quality of the paper is considered to be lower. The tensile strength of paper however depend on basic weight of the paper and indicated as N/m.

Read all others about paper -four part article- in the following links:-

Recent Comments