Students Guide for printing – 41

-Few objective Questions and answers-

Written by : N.R. Jayaraman

182) What general formula is adapted for packing Plate and Blanket on an Offset printing machine?

First keep in mind that every Offset machine has Blanket, Impression and a Plate cylinders. In some of the machines such as both sides printing called perfecting machines, two Blanket cylinders are fitted which act as Impression cylinder against each. The Plate and the Impression Cylinders have Under cut in them where the Plates and the Blankets are fixed.

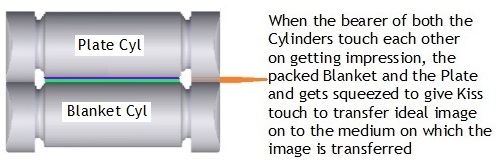

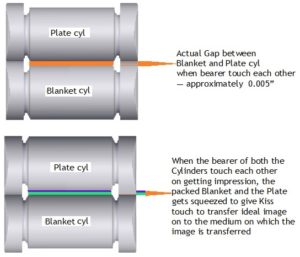

In most of the Offset printing machines, the optimum printing pressure gap between the Plate and Blanket cylinders are found to be between 0.004″ and 0.006″. The midpoint in them i.e. the squeeze pressure is approximately 0.005″. After the impression is put on, since both the cylinder bearers kiss touch each other and run, it is assumed that prior to giving the impression, approximately 0.005”* gap is held between the Plate and Blanket cylinders besides the Under cut depths of both the cylinders.

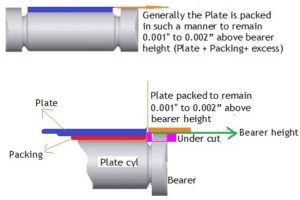

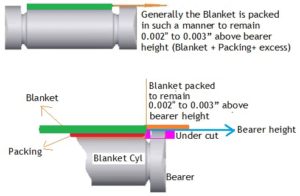

The second most important issue to be kept in mind is the Under cut i.e the gap between the lowest surface of the cylinder body and the actual outer surface (circumference) of the same cylinder which is technically called as Bearer.

Though the standard depth of Under cut varies between 0.018” to 0.020”, the technical manual of each brand of machines manufactured by various firms mention the depth of Under cut for packing purposes. Therefore the machine instruction manual has to be referred to know the depth of the Under cut on both the cylinders to arrive at the standard packing required for their machines.

Since the Plates and the Blankets are sold in different thicknesses and sizes, only the standard size and thickness Plates and Blankets that ideally suit the machine are procured. The deviation in the thickness if found any will be compensated with the packing material.

Keeping the above basic principle in mind, the general formula adapted to match Printing plate : Blanket ratio is given below.

Let us work out the packing formula for the Plate Cylinder with assumed figures:

(a) Undercut of the Plate Cylinder: 0.020” (See illustration to understand the Under cut)

(b) Plate thickness: 0.015”

(c) Remaining gap to be filled till bearer

height of the cylinder 0.005” (a-b)

(d) Extra packing suggested to partially fill

the standard gap above bearer height

of Plate cylinder for effecting perfect pressure 0.001″ or 0.002” (*out of 0.005” gap as explained in Para-2)

(e)Then the total thickness of packing paper required

below the Plate remains 0.006″ or 0.007” (c+d)

Thus to fill up the gap of a + d = 0.022″ or 0.023″, the Plate cylinder will be fitted with 0.015″ {(b) Plate } + 0.006″ or 0.007 {(e) packing}

Let us work out the packing formula for the Blanket Cylinder with assumed figures:

(a) Undercut of the Blanket Cylinder: 0.020” (See illustration to understand the Under cut)

(b) Blanket thickness: 0.017”

(c) Remaining gap to be filled till bearer

height of the cylinder 0.003” (a-b)

(d) Extra packing suggested to partially fill

the standard gap above bearer height

of Blanket cylinder for perfect pressure 0.003” or 0.004″ (*out of 0.005” gap explained in Para-2)

(e)Then the packing paper required

below the Blanket becomes (c+d) 0.006” or 0.007″ (c+d)

Thus to fill up the gap of a+d = 0.023″ or 0.024″ the Blanket cylinder will be fitted with 0.017″ {(b) Blanket } + 0.006″ or 0.007 {(e) packing}

However the above mentioned formula for Plate and Blanket cylinders with assumed figures have a large bearing on how thick the printed paper is used for printing. The above calculation is worked out assuming that the paper to be printed measures 80 GSM having 0.002” thickness. In case if a thicker paper is used whose thickness will be more than 0.002”, then accordingly the packing in the Blanket cylinder (and not Plate Cylinder) is reduced proportionately from the figures shown in above calculation.

Finally remember that all above are internationally accepted basic standard guide lines for packing of Plate and Blanket cylinders and based on one’s own practical experience, the best packing requirement needed to get perfect print has to be worked out.

Recent Comments