Alphabet – P / 6

26. Pica : Pica is the unit of measure in the process of hand composing . One inch is equal to 72 Points and a Pica is 1/6th of an inch i.e approximately 0.166 in. Therefore are 12 points make one Pica.

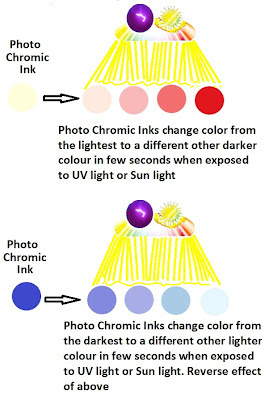

27. Photo chromic ink : Photo Chromic ink changes its color when exposed to Ultra violet rays or when viewed under Sun light. This special type of ink is manufactured for varieties of printed material such as Tags, Label Printing, Fun books, Comic books, Cards, Calendars, and also as security feature in some Brand protection labels or cartons, Novelties etc. The colorless or light colored image will show a bright color when exposed to Sun rays or viewed under U.V. Light and reversal of the color effect is also possible to show dark print showing diffused colour when exposed to UV light or Sun light . The change in the color effect is due to the U.V rays in Sun light altering the chemical structure of the molecules or pigments present in the ink which absorb the light and accordingly reflect them back. This should not be confused with the Optically Variable Inks that show different color when viewed from different angles or with Thermographic inks that change colors when rubbed or slightly heated. Few low value Photo Chromic inks are also manufactured for printing on textiles.

28. Pixel: The smallest dot of the image element seen on the computer.The dots will not be round in shape as in halftone print. The Pixels are several hundred single points of the image. Every image will consists of several hundred pixels or individual square dots that remain joined in continuous flow without break in between the pixels. The intensity of each Pixel is variable. While in Black and white images each Pixel is represented by shades of greys, in multi Color images however each pixel will be represented by different shades created by the combination of three colors –Red, Blue and Green- (RGB). The quality of the image in the computer will depends upon the size of the Pixels i.e and how many Pixels are in a square inch.

28. Printing paper : The term printing paper refers to all varieties of Paper used for different printing processes irrespective from which pulp they were made of. It also refers to both Coated and Uncoated Papers. A good printing Paper generally should have the following properties:

- Good absorption of the inked images

- Fluff free to run on Offset machines

- Good dimensional stability to withstand all sorts of temperatures in the press room

- Stay flat to feed without feeder problem on machines

- Good surface structure

- Uniform thickness and good Porosity

- Light weight, at the same time do not show through the image and

- Most versatile

29. Poster paper : The Poster Paper is a thin variety of Paper, surface calendared (Light weight ) to give gloss on it. The Poster Paper should not be of show through quality. Due to the super Calendaring on the front side, they will have gloss on surface and therefore the printed images will stand up in appearance. Though thin variety, they should be strong and durable because the Posters applied with some adhesive on their back side will be pasted on the street walls by rubbing the paper against the wall. During such rubbing process the paper should not tear. The Paper should also not fade quickly, withstand dust and dirt, stay strong on wall withstanding the furies of rain and wind.

30. Photographic paper: Any Photographic paper that is coated with some light sensitive material to produce positive image- either black and white or colored- on exposure through negative or positive is called the Photographic paper. They are also called Bromide Papers. Both negative working and Positive working Bromide papers are available. Some special variety Photographic papers which are dimensionally highly stable are also available. They are meant for the designers and artists. Though they come on polyester based material they are still called Photographic Projection Print Paper and the images produced on it will be similar to the ones produced on bromide papers. Additions or alterations are easier on this with black colored inks and white paints as they remain absolutely flat and stable. Both side Coated Photographic papers are also available which can be exposed on both sides and developed without affecting each side print.

31. Porosity : Porosity is the measurement of the paper surface that determine how much air can penetrate through its surface. The extent of Air permissibility will influence the absorption qualities of ink on paper, ink binding properties, strength of a paper etc. The Porosity will depend on the fiber formation during Paper manufacturing Process. Therefore in order to further increase the porosity of the paper they are subjected to Super Calendaring or surface sizing process to artificially seal the fiber gaps to reduce the level of porosity. Porosity is the measurement of the total connecting air voids, both vertical and horizontal, that exists in a sheet.

The increase in ink absorbency on highly Pores Paper can cause show through similar (excess penetration) of ink and the ink consumption will be more. At the same time Paper with less Porosity will cause ink smudging and blistering problems thus causing non ink drying leading to set off. Therefore suitable paper – with sufficient porosity level- will be required to print by different processes of printing. Porosity is an important factor when used on Web Presses.

For example in high-speed web offset printing such as those used for printing of newspapers, if the paper used lack sufficient porosity it may not rapidly absorb the ink to commensurate with the speed of the press and will cause set off problem. At the same time highly pores paper will curl and cause stacking in delivery. Therefore the paper used in each process should have sufficient, yet not high porosity.

Recent Comments