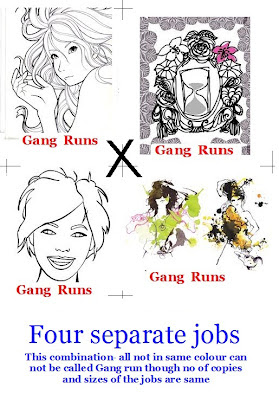

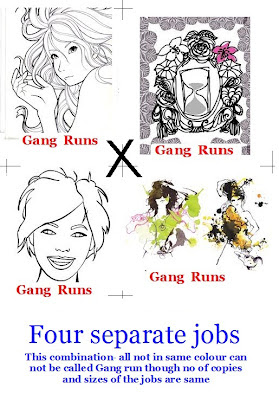

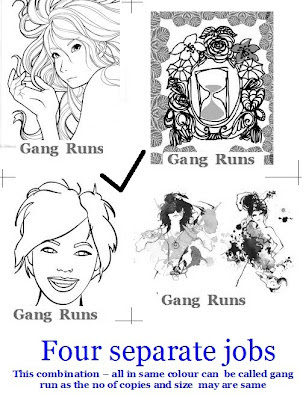

1. Gang Runs: Where the print runs , colors and also the sizes are same, they are clubbed in one layout and printed in order to utilize the machine effectively and to reduce wastage of paper. This is called gang run. On completion of printing the sheets are trimmed to actual size to separate each work. Generally the designs that have less colors or line work are combined and printed. Multi color work is not combined and printed as the color adjustment to various jobs can not be achieved in this pattern of printing.

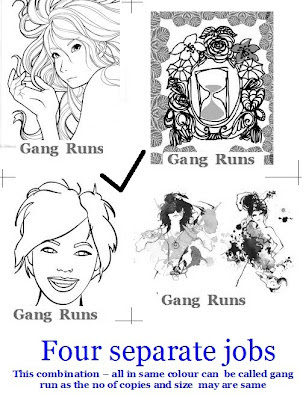

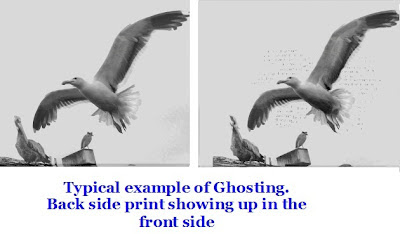

2. Ghosting: A faint image appearing on a printed sheet where it was not intended to appear. It may be termed as Ghost image. The Ghosting occurs when the printed ink excessively penetrates from the back side of the same sheet thereby disturbing the appearance of the printed image on the other side and vice versa especially where halftone images appear. One of the major reasons for this defect is use of thin paper, excessive penetration of ink into the paper due to non matching of ink with the paper, fountain solution emulsifying the ink in wet offset printing etc. Proper selection of ink with the paper stock being printed can help prevent ghosting.

Adjusting the layout itself can also help prevent of ghosting. If you have a layout that incorporates both areas of heavy ink coverage such as large, bold headlines on areas of lighter coverage on the back side, potential for ghosting on the printed sheet due to ink seepage would be higher. Therefore in such cases the layouts may be made in such a manner that the halftone images are avoided on the areas of the sheets in whose other side heavy text or image has been printed .

3. Gloss: The shiny surface of the paper called gloss can be derived in two ways. By running them between two polished stainless steel rollers at the end of the paper making machine, or adding certain loading material in the paper pulp and then passing them between polished stainless steel rollers at the end of the paper making machine.Some times the printed sheets are coated with glass like transparent thin layer of varnish to give gloss to the paper.

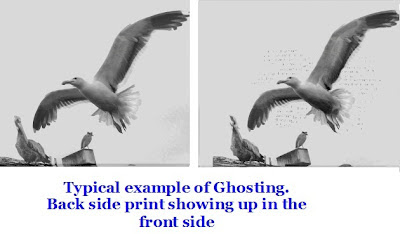

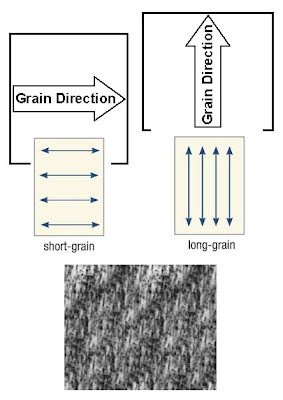

4. Grain direction: The direction in which the fibers run on the paper making machine is called the grain direction. Long grain paper refers to paper in which the fibers run in the same direction as the longest measurement of the paper. Short grain paper refers to the paper in which the fibers run in the same direction as the shortest measurement (width) of the paper. Also called machine direction, this factor assumes importance while trimming the paper for multi colour printing process as the expansion or shrinkage of paper is directly related to this.

The paper will get easily torn when torn parallel with the grain. Where the job requires folding, the printer will adjust the paper direction accordingly and use the paper. Experts say that the laser printers require long grain paper for the best results since the heat produced in the laser printers cause some curl in the sheets thus resulting feeding problem.

Paper gets folded easily and straight when folded parallel with the grain direction. Paper will curl easier in the opposite direction of the paper grain. The paper makers usually indicate the grain direction of the paper on the packing sheets. Paper is stronger and less sensitive to changes in relative humidity in the machine direction than in the cross direction of the paper.

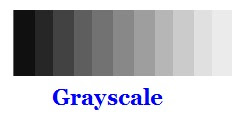

5. Gray scale: A photographically produced guide that contains multiple shades of black and gray beginning with white to black at both ends. This is inserted in the edge of the original while making negatives or positives in a process camera to assess the quality of reproduced negatives/ positives. The processed film negatives/ positives images will be compared with the grey scale to confirm whether the processed film has correct tonal values as per the original. In short the Gray Scale is a quality control device that helps compare tonal values of reflection copy with its reproduction. By comparing the processed films with grey scales one can correct the exposure and processing conditions to balance the negatives and positives especially in a color reproduction process. Since the Grey scales are not a simple white to black tonal strip which can be prepared by spraying the tonal values on a sheet of white board, they are to be procured from the Photo film firms only as they have been specially prepared in a scientific manner so that the Grey Scale procured from any photographic firms will have the same tonal effect when compared.

6. Grippers: Small metal fingers found on the printing machines which grab and hold the paper during transfer of prints from plate to the paper. This is also a device meant to transport the paper. The grippers may be found on the impression cylinders where the paper is held tight to undergo impression and also are fitted in the delivery chains that take the paper from the impression cylinder and hold them firmly till the sheets are dropped on the delivery board. If the grippers in the impression cylinder fails to hold the paper properly, it can cause mis register of the images. Therefore setting of grippers is as important as any other vital settings on the machine.

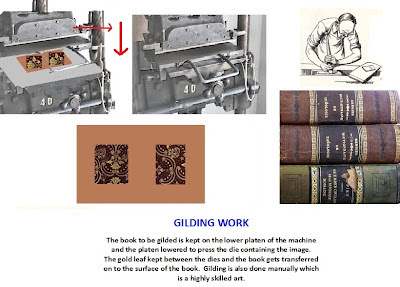

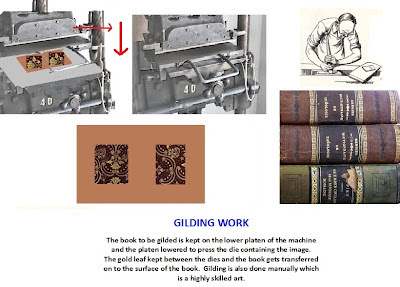

7. Gilding : The books kept as achieves or in libraries are normally bound with a full leather or rexin cover. In order to quickly see the subject of the book, and to act as an eye catcher, the names, volume, and year of the collection are embossed in gold lettering over the leather case by a process called gilding. Gilding is nothing but decorating the contents over the cover by a special process called gold gilding.

Do not confuse it with Gold embossing or debossing. This is a different technique by which ornamental designs are added on the cover. Some times the entire front cover will be gilded with some design using hand operated gilding machine. The text matter is composed with metal types and mounted in a special frame and slightly heated. The metal type i will then be pressed against the leather case over a Gold foil paper kept over in place where the text matter is to be printed. With the heat, the foil firmly gets adhered on to the leather base. Since the leather cases can not be printed on the printing machines and can be subjected to only screen print which however does not give such a glitter effect to attract the eyes easily, gilding process which is oldest technique is employed as part of work in binding.

8. Gloss Ink : Special glossy ink that dry by oxidation cum evaporation process without penetrating into the coated stock which gives effect of shining to the texts printed . Many varieties of glossy inks available in the market.

9. GSM or Grammage : Basic weight of paper expressed in terms of ‘grams per square meter (gsm)’. In other words, a square meter of a specific type of paper will weigh a certain number of grams. The GSM indicates how dense the paper is and help the printer decide suitable paper for suitable job. The general principle is, when the GSM is higher, then the paper will be thicker. GSM also help to calculate the weight of a ream of paper so that the cost can be worked out as the paper is always supplied in weight. The GSM is determined by weighing a known size after conditioning the sample for 24 hours in ideal press room condition having 23°C temp and 50% Rh .

To find out the GSM of the paper the following formula can be used:

1000 x 100000

———————————————————————————-

Weight of paper in Kg x length x width of paper in mm x 500

To find out the weight in Kg of the paper the following formula can be used:

GSM x length x width of paper in mm x 500

————————————————————

1000 x 1000000

…………Additions to alphabet G to be continued under G/2

Recent Comments