Alphabet – D/2

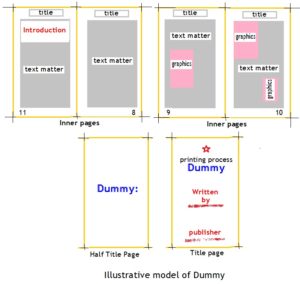

The same is the case when the films used for making plates are processed. The film substrates which form the film bases show a high sensitivity to variations in temperature and humidity. Despite numerous layers and coatings associated with the emulsion layer, the base generally accounts for the vast majority of dimensional stability. For example the thin films with Acetate bases reportedly have less dimensional stability than those with Tri acetate, Polyester, Easter, Cronar, Mylar® bases , some of which are the proprietary products of some of the photographic firms.

Therefore while processing the films for making plates, the negatives are processed on the same day with the same set of films, developers and chemicals since any change in the dimensions of the films will also lead to mis-register of the images printed. In view of the general tendency of the films subjecting themselves to dimensional changes due to the changes in the atmospheric conditions, printers prefer to use glass films as they have greater degree of dimensional stability.

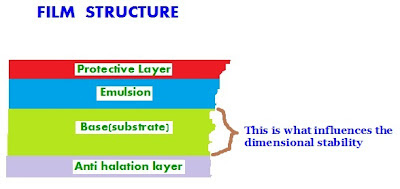

11. Desktop Printing or publishing : Called DTP, this is fast developing technology to print jobs of lesser quality and lesser quantity jobs as this process requires no plates or blocks or types to render printed image. The copy for the print is neatly typed, assembled with graphics etc and used as original and printed like automatic photo copier. In short this can be called a glorified photo copier or a duplicator. This printer can be directly connected to computer to feed the data or assembled copies that require to be printed. Many printing companies use desktop publishing equipment for their smallest orders because it is much cheaper than using large mechanical presses for small quantities and their delivery time to the customer is very short. The typical desktop publishing system consisted of a personal computer, a printer, and the appropriate software to carryout the entire operations. On Desktop printers only flat substances like flat paper and films can be printed. Boards or other objects can not be fed and printed.

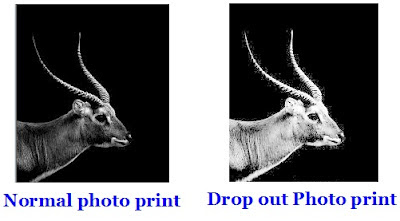

12. Dropout : Halftone dots or fine lines eliminated from highlights by overexposure during camera work. This is sometimes done by adjusting the exposure time in the process cameras when the negatives or positives are taken. This technique is adapted to enhance the appearance of the originals which contain flat tonal values.

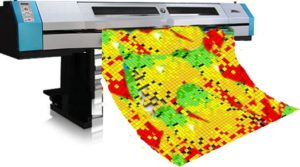

13. Digital Printing: In one manner this also falls in the family of DTP. This is a process in which the image is created on the computer in the form of digital signals and transmitted directly to the output device i.e. the printer. Digital printing is a printing technique using digital or electronic files from a personal computer or other digital storage device as a source. No pre-press operation including making of negatives from the composed matter, assembling of layout etc, or making of printing plates are required. The prints are taken from the layout created in the computer consisting of both text matter and the photographs or illustrations of many types including the colored ones on the computer itself and thereafter printing the same on to the desired substance with liquid ink-jet, wet/dry toner systems, solid ink-jet, thermal-transfer etc. Due to lower production costs, and short period of time involved in Digital Printing system it has replaced Offset printing in the world of print market.

One other important advantage of Digital printing is the possibility of printing variable Data using information obtained from the database or external file. The texts and graphics can be changed on each sheet without stopping or slowing down the machine. For example, personalized letters can be printed with a different name and address on each letter.

By digital printing even big sized posters of only few copies can be printed in the shortest time provided the press owned a digital printing machine which can take paper from the reel to print the copies. Though the general purpose digital printer comes with only four colour cartridges with whose combination the multi colour printing is carried out, many Digital printers are also available to to print more colours with more no of colour cartridges fitted which work in combination to produce desired colour effect. By Digital printing process reels of paper, flat paper or even uneven surface substances or articles can be printed. The advantages of Digital printing is:

- It is possible to print variable data obtained from the database or external files.

- The position and colours of the texts and graphics can be changed on each sheet without stopping or slowing down the press. For example, personalized letter or advertised material can be printed with a different name and address on each one of them.

- It is flexible process which need no pre-press operations.

- Even bigger sized posters of only few copies can be printed in the shortest time on some of the Digital printers which can take paper from the reel to print the copies.

- The Digital printing is boon to the packaging and pharmaceutical industry where the variable data print labels and cartons are needed for packing the material.

- The printed brochures, advertising print material, fliers, posters, banners etc could be easily reproduced by the Digital printing machines at a faster and economical rate compared to conventional processes of printing.

- Besides speedier and faster delivery of the print material, intricate designs which the conventional print processes could not offer in shortest period of time can be accomplished by the Digital Printing process.

- The Digital printing technology offered varying surface finishes of the same designs, high depth three-dimensional graphic designs etc.

- The Digital printer equipment save space.

- It is best suited for printing small quantities of jobs, instantly needed prints and on demand printing which are required in the shortest possible time.

Paper wastage is avoided.

Matching true color is easily done on the computer before printing on the substrate.

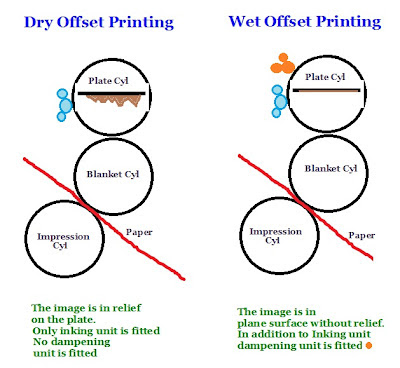

14.Dry Offset : Printing on Offset machines using Photo polymer base plates with relief images (like in letterpress blocks) is called Dry Offset printing. One can therefore call this Water less Offset Printing (WOP). Unlike in letterpress, the images on the dry offset plates will be in readable form since the images are printed through intermediately blankets. As the name implies dry offset, it refers to the absence of dampening unit on the machine in contrast to wet offset lithography wherein water is used to dampen and repel oil-based ink from the non-print areas of a printing plate.

Since the water ink balance has to be maintained in the Wet Offset, which if not properly handled causes press related problems like plate blinding, scumming etc, Dry Offset presses print faster without much technical problems. It is also easier to make the plates for Dry Offset and also is a high speed process with low cost. The additional advantage is changeovers of the jobs are easier and simpler to handle compared to wet offset printing.

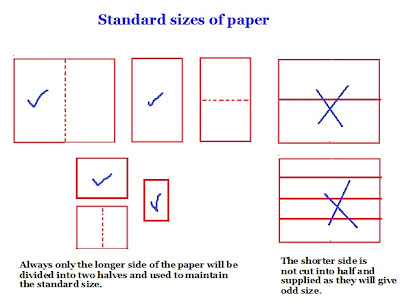

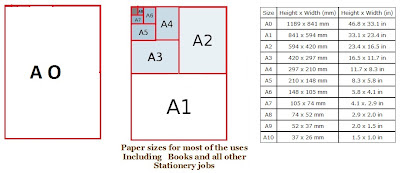

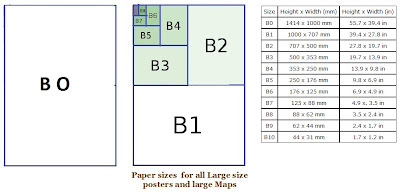

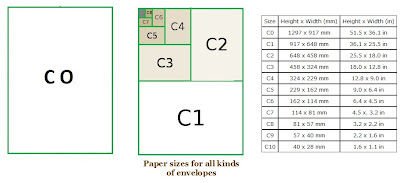

15. Din sizes : When the saga of printing began, paper manufacturers produced paper in different sizes. Each country had their own sizes of paper. Some of the popular paper sizes in use included sizes like Demy(171/2’’x 22 1/2’’), Medium (18’’ x 23’’), Crown (15’’ x 20’’) , Imperial (22’’ x 30’’), Royal (20’’x 25’’) etc. This could not standardize the sizes of books and other printed material and led to paper wastage besides under utilization of machinery and equipment. Therefore in the year 1920, in order to standardize the paper in use in various countries one of the German institute of standardization began standardization process for paper known as DIN a short title for Deutsche Industrie Normen . Later the DIN standard was replaced by ISO standard by International Organization for Standardization. The international paper size ISO is however based on the DIN size only. The papers were manufactured based on the standardized sizes namely A, B & C, so as to have their subdivision fall in the same proportion.

The advantages of standardization are obvious for efficiency of paper production, manufacture of printing equipment, print production, storage, calculation of weight or their conversions etc. There have been many standard sizes of paper in use at different periods of time and in different countries, but today there are two widespread systems in use: the international standard sizes (A4 and its siblings) and the North American sizes.

ISO paper sizes are all based on a single aspect ratio of square root of two. For example the Ao size of paper is defined to have one meter square. The subsequent sub divisions of the ‘Ao’ sizes are ‘A1’, ‘A2’, ‘A3’, ‘A4’, ‘A5’ etc which are just half the size of the paper when cut into two on their longer side. The system allows scaling without compromising the aspect ratio from one size to another – as provided by office photocopiers, e.g. enlarging A4 to A3 or reducing A3 to A4 and so on.

‘A’ series of paper are the most popular and most practical and used for general book and all varieties of stationery printing. ‘B’ series is intended for larger print work such as posters and Maps. The ‘C’ series however are meant for the envelope sizes designed to compliment the ‘A’ series sizes.

Recent Comments