Latest developments in the printing world

New developments keep on emerging for upgrading the systems or technology in printing to help the printers improve the productivity with speed without compromising the quality so that they can be a competitor for best bench marking to attract more customers. Automation on machines have been introduced to partially or fully replace the hereto performed manual activities on machines to speed up and regulate the flow of work. Generation and analysis of data directly from the machines are also made available through inbuilt systems on machines for speedier and trusted data. The generation of such data enables the printers to analyze them for effecting improvements wherever it is possible to effectively compete in the world of stiff competition.

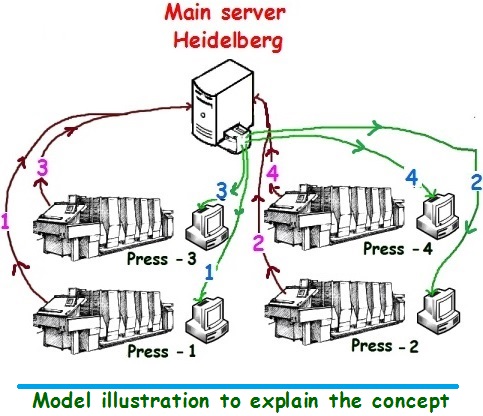

In this direction, pioneers in the field of manufacturing and supply of printing machines and equipments, M/s He

idelberg, Germany has come out with a system that enables the printer across the world to compare their performance with that of other presses where same type of printing machines as theirs are deployed for production. The data thus accessed for comparison from a level playground will help the presses to improve their productivity. The system offered by Heidelberg is called ‘Prinect Performance Bench marking’. Few technical requirements are necessary for participating in the Prinect Performance Bench marking programme. The presses must be equipped with Speed master printing machines and those Speed master presses should have Heidelberg’s web-based remote service which is to be activated, and that they should be equipped with software version S10A or later for the Prinect Press Centre.

The presses which have engaged Speed Master machines for productive activities if agree to participate in the performance analysis programme, will have to activate the data transfer process through remote service technology so that the production data and performance of the machines are transferred to the main server installed in Heidelberg central unit. Remember that the central server at Heidelberg which receives the performance detail of the printing presses around the world are on a completely protected database and no information will be used without the consent of the specific printer. As and when the data and the performance of all the connected machines automatically get transferred to the main server, the server continue to update the bench marking data by continuous evaluation of the data stored in the server. Thus performance of various presses connected with the central server over the chosen parameters is compared with the average performance of other presses whose identity will however remain anonymous, and the best performer from among them will be identified.

One can certainly ask as to how this kind of data transfer will help the presses ? By participating in this programme the performance analysis of similar machines in other presses will be available to the presses who have also installed the same type of machines. Using the Internet-based Prinect Performance Bench marking data from Heidelberg, the presses can compare their own performance with the same set of technologies and machines, and this might actually help the printer to catalyze the production in their units by reworking or modifying the methodologies or technologies wherever possible to compete with the best printer.

Is there possibility of misuse of data or information of any particular press ? Heidelberg says that the printer can be rest assured about the security and confidentiality of the data extracted from their machines. Heidelberg has ensured that appropriate and effective security measures have been put to place to keep the actual inputs confidential, and the said data is not used for any other commercial purpose other than for Performance Bench marking evaluation of their machines. No other participant can gain access to any other information of those presses.

M/s Heidelberg states:

Quote:-

All Speed master presses supplied by Heidelberg are connected through Remote Services to the Prinect productivity server in Heidelberg. When you switch on the OK sheet counter, production data automatically starts getting recorded. It then gets transferred to the productivity server on a daily basis, and the evaluation is done on the server. Printers who choose to participate can access the productivity server themselves through the Internet. The Prinect Online Portal is designed such that you can see the production report from your press displayed alongside the anonymous comparison data. This allows you to compare the performance to the average productivity of the connected presses, and also with the best performer of the lot.

:-un Quote

One can certainly ask ‘how could the comparison be possible when each press print different types of jobs, each varying in quantities, have their own standard of working etc even though the machineries are same like the best bench marked press’ ?

For example on a specific size of paper used, one press may print only two pages laid out work, other may print multiple ups, say four pages but smaller in size and others even twelve up playing card size job work or product labels. How then could the comparison of productivity be possible?

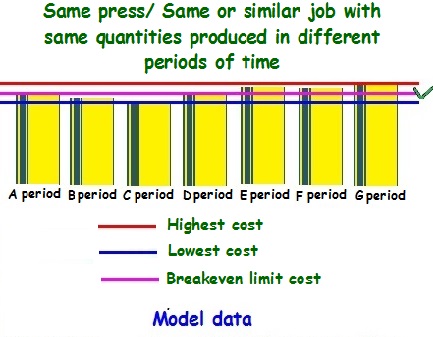

Generally the self performance assessment is carried out by the presses using annual expenditure and income – as final yardstick. Taking into consideration several factors the presses work out the cost of printing either per page or per 1000 sheets of specific sized paper which includes profit/ loss margins. This is compared with the cost of printing of the same with other presses to assess where the improvements could be carried out to reduce the cost to compete with the presses who offer lesser rates than them. However the cost of printing, either per page or per 1000 sheets of specific sized paper that includes profit/ loss margins may vary over the years, not necessary that it will only escalate, it may even come down. Therefore a breakeven limit where execution of job at ‘x’ rate will not incur loss will be derived by compiling data of several similar jobs of same size and same quantity executed at various period of time before arriving at the breakeven limit figure.

In this manner when the data is generated by the press for each specific type of job they have produced, there will be set of data available for each kind of job produced which will form the basis of the chart for comparison. Remember, the figures may continue to change each time a fresh order is processed because of variations in the cost of material procured.

When exactly similar job is produced in a press having same type of machineries and equipments then whenever the same type of job is produced by them, they can compare break even limit cost of others provided such data is available. If made available and analyzing the data they can track down the critical factors that hike their cost and take corrective measures to improve the working to reduce the cost to remain competitive. This is the general principle and theory practiced to remain a competitor in the race of front runners in attracting the customers.

On the flip side the general comparison for overall performance of presses is also done based on only few factors like :

- overall size and type of machineries deployed- fully automatic or semi automatic kind of machines-

- single colour or multi colour machines

- average speed on which the machines are run

- no of jobs produced per annum total output achieved per annum clubbing all jobs

- average output achieved per annum

- annual loss of machine hours lost due to breakdown -separate figures for technical problems and malfunction of machineries

- average no of personnel deployed per annum

- type of process deployed

- type of substances used for printing

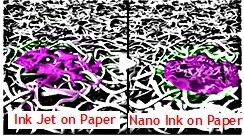

- type of ink used- quick drying, UV drying or other means of drying

- average expenditure incurred on men and material per annum

- OVERALL COST OF PRODUCTION PER SQ.METER OR PER PAGE OF ‘X’ SIZE OR PER 1000 SHEETS OF ‘X’ SIZE THAT INCLUDES PROFIT/LOSS MARGINS BASED ON ABOVE

While the author is not sure what parameters are considered and applied for generating data for bench marking of the presses who participate in the programme of bench marking introduced by Heidelberg, the concept of comparison of performance, based on data from very similar machines across the world is something new in the print world introduced by them.

In today’s competitive print environment, knowing what the costs are and how to optimize the use of equipment and machineries has become essential in establishing sustainable business practices to ensure long term success for the press. Heidelberg claims that ‘with their press reporting technology, print managers can decipher exactly what each print job costs to produce, both in materials and in time. Heidelberg further claim that the benefits are many for the presses who agree to participate in this programme.

It is reported that the Prinect reporting solutions provide independent and unbiased reports and are easily accessible on a computer with internet connection. With a high level of graphics displaying details of data they are easy to read. In today’s stiff competitive world of printing environment, where runs are getting shorter and costs are increasing, it is more essential to know exactly at what level the operational costs are to be contained to have an edge over others for establishing sustainable business. The data from others are needed for time to time evaluation and to effect changes in the working procedures wherever needed without affecting the overall working atmosphere. Access to this kind of detailed data enables the presses to streamline productivity for maximizing the profits by reducing the wastage to deliver enhanced service to customers to retain the hold on them.

According to Heidelberg some of the benefits of this exercise are:

Quote:-

- Direct comparison of productivity on the basis of the latest data

- Options to choose the comparison parameters for your machines

- Transparency of national and international markets

- Regular updating of anonymous benchmarks, giving you a standard to compare against

- Adjustable comparison classes

- Availability of effective tools that let you optimize your processes and cut costs

:-Unquote

Recent Comments