Alphabet -P /3

13. Perf Marks: The dotted print Marks usually seen at edges where perforations should occur is called the Perf Mark or Perforating mark . Read more under Perforation below.

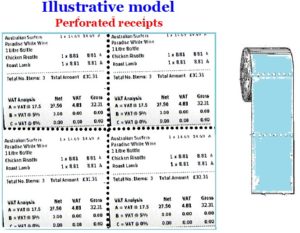

14. Perforation: The process of piercing small continuous holes in binding stage to facilitate easy tearing or folding of the printed material is called Perforation. The best illustration is the perforated stamps to tear individual stamps for issue; invoice books, bill books, receipt books , cheque books, challans etc where counter foils are to be kept in the book itself and the original has to be torn and given to the customer. Several such printed material in common use. Their top sheet will have perforations to tear them to issue to the customer. It is possible to perforate both in sheet form as well as on rolls. The perforation is done not by piercing individual holes in a row, but done in the perforation machine containing row of piercing pins. Small presses get the small order jobs done on the sewing machines also by passing the sheets like stitching the cloth. The bigger size tissue paper rolls are perforated on a web perforation machine attached at the end of the paper making machine or separately got done on a web machine fitted with perforating pins. They are then slit to required width sizes and wound on rolls.

The term perforation is not limited to facilitate tearing of the sheets of print material alone. The perforation is also one of the important security feature available in the security printing field. It is called Microperf Standard Image or Microperf Latent Image patented by a firm Orell Fussli in collaboration with world renowned Security machine manufactures M/s KBA-Giori of Switzerland, and the said process is done by laser beam cutting technology that keeps the holes crystal clear. Since such devices used to protect against counterfeiting have to meet high standards, only world renowned specialist security machine manufacturers like KBA- GIORI are able to do it.

Quote (https://www.snb.ch/en/iabout/cash/series8/id/cash_series8_security) :

The numeral in Swiss 100 frank notes is made up of very fine perforations, a feature known as microperf®. (Initially, the perforated number was used on the large banknotes only. Since 2000, this feature has also been incorporated into the 10, 20 and 50-franc notes. Until all the banknotes have been replaced, small denominations with and without the perforated number will be in circulation. Both versions will, however, remain legal tender.)

Test: : When held up to the light, the denomination appears as a perforated surface

Unquote

Perforating is also done for cancelling or validating some of the print material through special machines made by some of the firms. Instead of continuous running punch pins, readable words like Cancelled, Paid are produced on certain documents like tender documents, identity documents, saving books, Cheque leaves submitted or various other important business communication documents through such pre fabricated piercing perforating pins. There are special perforating wheels- like numbering wheels- manufactured by specialist firms that effect perforated dates or perforated codes on print materials by rotary presses.

15. Photoengraving: This is one of the oldest photo mechanical etching processes which is meant to make relief plates or blocks for printing by Letterpress process. Since Photographically formed images on a metal plate is chemically etched to get the print imaged plate, this process is called the Photoengraving process.

The Photoengraving process involves making a laterally reversed negative from the original art work using a prism in the process camera, and then transferring the image on to a photo sensitive material coated metals such as Zinc, Copper, Brass or Magnesium plates.

The photo sensitive coated plates are then exposed with the negative and the images are formed on the plates. The plates will then be washed with water. Since the image areas will remain hardened during exposure, they remain unaffected while washing with water. Then the image areas will be applied with a acid-impervious ink which will cover the top of hardened image areas. Once the acid-impervious coating dries, then suitable acid solution is applied over the plate to etch the non image areas. The acid will bite the bare metal areas, which are actually the non printing portions, and dissolve them allowing only image areas in relief. At some stage when deeper engraving is still required an acid resisting powder called dragons blood will be applied to the side walls of the engraved images with some thin brush to protect them from getting etched. The longer the plate is exposed to the acid, the deeper the bite will be and therefore the stronger the relief.

Different depths of the image areas are achieved by covering some lines with acid-impervious varnish called stopping ink. This is an intricate process and if well handled will produce images comparable to hand engraved images. Of course there are limitations in this etching process especially when halftone images are prepared. It would produce good result when line work or coarse halftone work is produced in this process. They will not give very good result on fine screened halftones. Photoengraving process is best suited to process originals made from woodcuts, wood-engravings and linoleum cuts.

16. Powderless etching: The Powderless etching process is a step forward in the Photoengraving process. As stated above under Photoengraving process, instead of other metals Magnesium plate is coated with a suitable photo sensitive material and then exposed with the negative to harden the image areas. Once hardened image is formed the plate will be as usual washed and cleaned and dried. The image areas as hardened coating remains on the plate. The plate will then be slightly heated to make the hardened areas turn more harder. Then the plate is etched with Nitric acid mixed with some oily solution called wetting agent and the plate dipped in it till sufficient depth is achieved. The acid will bite the bare metal areas, which are actually the non printing portions, and dissolve them thus sharpening the images. There is no need to protect the side walls with acid resisting powders or paint with acid resisting black ink before etching. Since application of acid resist paints or powders are not required during etching process, this process of producing the Letterpress printing plate is called Powderless etching process. Powderless etching machines are also available in the market to facilitate easy working and to get very good result, as the acid solution is sprayed on the plate uniformly.

Recent Comments