Alphabet S /5

22. Sizing : This term is very important in the paper making process and refers to the chemical which is used to smoothen the surface of he paper. This material fills up the inter woven fiber gaps called porosity. This will also prevent the paper from absorbing too much moisture. Sizing also protects the fibers from breakdown due to oxidation and add strength to the fibers . Sized papers show a considerably higher strength.

23. Stripping: Stripping means assembling elements of composed texts and material to make them in one format or one page before processing for printing. Stripping is also called a film assembly or an image assembly. How is the stripping work carried out?

Some of the print jobs may have both illustrations and text material in each page. If the illustration is a line work, it can be pasted along with the text matter and negative can be straightway made for further processing. If the text matter and continuous tone work is to be combined for printing, first the continuous tone photo has to be converted to halftone and clubbed with the text material in which the process of Stripping comes in. How the text material with illustration is combined and how does the tripping plays the role?

The process of Stripping for a single page print material or a book is the same. In general first a dummy (Model) will be made indicating the text matter and position of the illustrations. Thereafter a master layout to actual final print job is made on a sheet of Astralon sheet flat film (or any other highly dimensionally stable film base) which will act as a guide to position the negatives containing the text material and the illustrations and joined together with cello tapes and further processed.

Supposing it is the case of a book work for Offset printing. The entire manuscript will be composed and the running text matter will be split to fit each page based on the pre-prepared layout and pasted showing register marks and page nos etc. Those individual pages will processed further to get negatives. Those negatives will then be joined together keeping them in correct position based on the master layout (astralon transparent sheet showing layout position of each page and register marks) for processing further to make plates for printing. This process of assembling the text matter as well as processed negatives is called stripping process.

While assembling the negatives or text material the illustrations to be incorporated will also be pasted in appropriate position or attached in appropriate positions of the negative on which required blank space to accommodate the illustrations may have been provided already. Once the illustration negatives are made, page by page the illustrations will be combined with the text material by cutting windows and pasting the illustration (negatives) in the said window and cello taped to hold them in position and further processed (See the illustrations to understand the process of Stripping)

In the case of photo composing machines where you get the direct negatives, the space for pasting the illustrations will also be given and composing of the text continued. Each laid out sheet will indicate the place where the illustration will appear.

The next step is to make negatives from the originals supplied.

24. Screen Ruling : Read further under Halftone. The screen ruling indicates number of lines per square inch that makes the halftone screen. The finer the screen ruling, the finer the halftone dots will be produced.

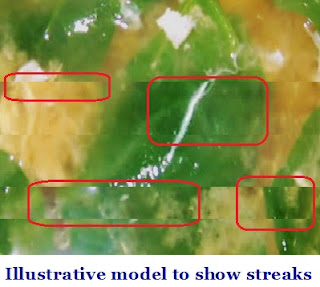

25. Streaking: This is one of the printing defects that is commonly witnessed in Offset printing. The streaking will show a dark streak of image in rows at a particular point of run. This defect could be due to several reasons such as improper Cylinder bearer adjustment, worn out gear, worn out bearings on rollers or cylinders or may also be due to ink drying. If the inking form roller is not properly set with plate cylinder it can also give a bounce and cause this problem.

26. Sheet fed machines: Machines on which only cut sheets of paper can be fed for printing. The Sheet Fed machines can not print paper reels. In sheet fed printing machines two varieties of feeders are available.One is called sheet feeder and the other called continuous feeder. Read details of the sheet feeder and continuous sheet feeder under feeder system.

27. Serigraph Printing: Serigraph Printing is another name given to Screen printing. The screen printing was earlier called Serigraph printing because the word Serigraph is a mixture of Latin and Greek word meaning Seri =Silk and Graphic means drawing.

Recent Comments