Alphabet – U

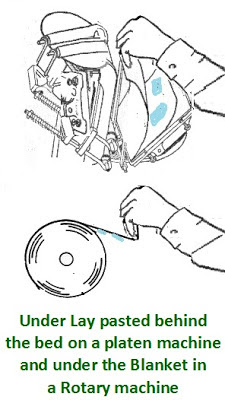

Underlay: On the printing machines when the impression pressure is not uniform, some packing in the form of thin paper is placed below the Impression bed or below the blanket to raise the non uniform surface on par with the level of plane surface. The process of inserting such packing material is called the Under Lay.

On Letter press printing machines the localized packing is given below the impression bed to get more impression on certain areas. On Offset Printing machines the packing is given below the blanket . On Offset machines sometimes uneven thickness of the blanket surface may cause impression variation and in order to rectify the defect, the packing is given.

- To compensate the varying thicknesses of Plates or Blankets used on the machines. Even though the plates and blankets are supposed to have uniform thickness, during manufacturing process, some thickness variation can occur and therefore they may require to be compensated.

- To increase or decrease the desired print density.

- To compensate the paper stretching which results in image variation in multi color printing thus causing mis register of subsequent printing. The said problem is compensated by adjusting the packing in plate and the blanket cylinders to increase or decrease the print length marginally. Adding or decreasing the packing under the plate or blanket cylinders will increase or decrease the diameter of the Plate or Blanket Cylinders by packing sheets.

More under packing packing under blanket cylinder will increase its circumference and lengthens an image, while adding more packing to the plate cylinder shortens an image. The procedure varies slightly depending on whether the press is a bearer-contact press or a non-bearer-contact press.

2. Unjustified: This word in printing refers to the composed text material not aligned perfectly on the right side of the margin while the same text material is pin perfect alignment on the left side i.e beginning from a fixed point on its left side. The said non aligned matter on the right side is called ragged to right or Unjustified typographic matter. Generally all the books and News papers will have the types justified on the right side to increase readability and to give pleasing look to the eyes.

4. Under run: When the print order is received sometimes it may so happen that due to extraneous reasons or over spoilage or due to technical fault on the machines, less no of copies may have been printed on some of the pages against the total printed copies required. If the quantity is much higher it can be reprinted. But if it is marginally found lesser, it will not be economical to print the short run pages. Thus the total quantity of printed materials which were found to have been printed less than what was specified in the original order is called Under run.

5. Undercut: On an offset Rotary printing machines the Cylinders rest on bearers instead of on gears alone. The bearers can be seen as a metal ring like arrangement provided at both the ends of the Cylinders on which both the Cylinders revolve. However when both the cylinder bearer touches each other, some gap can be seen. The said gap is called Under Cut. The gap is due to the low circumference of the blanket cylinder compared to the bearer level of the same cylinder, which is provided to fix the blanket.

When the blanket covered blanket cylinder touch the impression cylinder on getting the impression, the image gets transferred on to the paper surface. There will however be no under cut on the impression cylinder as it is not covered with any material and will remain as a smooth surfaced metal body. However note that the Plate cylinder will have undercut for fixing the plates to bring it to the bearer height to transfer the image on to the blanket cylinder. The Undercut has been made to accommodate both the Plate and the Blanket and to provide room for packing below both to adjust the image quality.

6. Unleaded: Typographically when the matter is composed, no space will be provided between two lines by inserting a space called lead. Such a composed matter made ready for printing is called unleaded type matter. The lead consists of thin lead to thick lead of varying thicknesses to suit different jobs and they are called spacing material.

7. Upper case: In Typography all the capital letters of the type faces- are called Upper case letters and in the hand composing type case all the upper case letters will kept separately in the right side of the type case. The compositor, who is responsible for composing and arranging the letters to make it ready for printing would stand before the slopped two wooden cases which are divided into several boxes or sections to accommodate all the letter, both capital, small, capital and lower case letters and other symbols. Capital letters are stored in the Upper drawers and the regular letters in the lower drawers.

Recent Comments