Graphic Arts Research, Machinery development and Training Institute

Whatever be the case, I am sure that the excerpts reproduced below from the report will be a vision document for study and research in printing and a valuable guide to all those who may pursue such ventures.

GARMTI: Report – An analysis

As per the Report of the Committee, in mid 1972, the National Committee on Science and Technology (N.C.S.T.) of the Govt of India constituted a planning group on Heavy Engineering with the following objectives.

- to identify gaps in technology particularly for the 5th plan but giving due consideration and weight age to long range objectives.

- to identify the agencies and experts capable of taking the related research, design and development tasks

- to work out a strategy and time bound programme for bridging the identified gaps in technology, covering the complete innovation change from concept to commercialization.

The report mentions that one of the most important recommendations made by the Planning Group was the establishment of an Institute for taking on the development tasks in the Printing Industry , Materials and Processes and Allied industries. This recommendation to establish an Institute for the development of Printing Industry was approved by N.C.S.T. who subsequently took up the task along with the Ministry of Heavy Industries. The Planning Commission also agreed to the establishment of an Institute of Printing under Heavy Industries Ministry during the fifth five year plan. A provision of Rs 1.75 crore was initially made in the fifth plan under the Science and Technology budget for the Ministry of Heavy Industries by Planning Commission. It therefore became necessary for a project report to be worked out for this institute and the Dept of Science and Technology under Govt of India took up the responsibility for the preparation of the project report and appointed late Shri. R. Ramaswamy, the then O.S.D of Bank Note Press, Ministry of Finance, Dewas as the Chairman and requested him to constitute a suitable committee for the said cause. Accordingly a ten member Committee was constituted under the Chairmanship of late Shri R.Ramaswamy for preparation of the project report for the proposed research institute.

Unaware of the development, the Board of Studies in Applied Art reconstituted the Printing Technical Committee to review the education in printing and included submission of comprehensive proposals for setting up of a Research and Development Cell for implementation in the fifth five year plan as one of the terms of reference. After several discussions, the report of the Committee on the establishment of the Research and Development Centre for the Printing and Allied Industries was approved by the Applied Art Board Committee. Two members were also appointed to prepare the Project report.

Incidentally two of the members were common in both the committees one formed by N.C.S.T under the Chairmanship of late Shri R. Ramaswamy and the other by Board of Studies in Applied Art. During deliberations the piquant situation (formation of two committees under different Ministries) was brought to the attention of N.C.S.T.

In view of the formation of two Committees set up by different Ministry’s for the same purpose, it was felt that India could not afford the luxury of two separate institutes for the same industry, and therefore in consultation with concerned Ministries it was decided that the Committee formed by N.C.S.T. would also study the needs of both Heavy Industry and the Education Ministry and prepare the Project report which however would be submitted to the Department of Science and Technology who will then forward the report to both the Ministries. The Committee held several discussions on various issues involved and compile the initial report .

Under the heading Environment in the Printing Industry the Committee recorded their observation as reproduced below:

Quote:-

During last few decades considerable design changes have taken place on Machines and the Industry has made use of Electronics. On Typesetting the use of phenomenal speed Computer aided composition in place of decade old Hot metal typesetting have advanced. In actual process of printing, great progress have been made in Offset and Gravure in a bid to eliminate Letterpress printing. These developments almost eliminated the use of Letterpress printing for use on high speed printing sphere. To keep pace with the increase in machine speeds, improved quality of products and sophistication in machine designs, far reaching developments have also taken place in plate preparation and plate making.

Today we have electronic scanners, pre-sensitized plates, direct image plates, automatic plate processing equipments, sophisticated cameras and enlargers, powderless etching machines etc, each contributing in their own ways towards increasing productivity, higher machine speeds, improved quality dependence and minimizing human judgment skills. These developments have been largely on results of consistent efforts on the part of the printing machinery builders and number of research organizations committed to graphic art research. Amongst the important reasons for the rapid progress taking place in the Printing Industry is ready availability of expertise developed over a few decades backed by the required capital. There are very few constraints and processing materials like films, plates, chemicals required by all the processes can be had plentifully. On account of the expensive labour consequent on post-war manpower shortage and the growing need for printed products in a highly competitive market, there has been a great emphasis on labour saving methods and improved technology.

-Un Quote

In respect of Indian Scene the report mentions the following :

Quote: –

In India the Printing Industry has not been given the status of an industry and a large portion of Printing Industry still uses the letterpress process. The more important reasons for the lack of development are (a) capital is both scarce and expensive severely restricting imports (b) the printing trade itself has been more based on a craft oriented system, where as it has become a scientifically and technologically oriented industry in the developing countries and the craft skill has been given place to technology and (c) indigenously available raw materials are expensive, sub standard and inconsistent in quality.

While reviewing the present state of the Printing Industry in India one must be careful enough not to overlook the fact that thousands of small printing presses are located throughout the country whose names have never attracted the attention of the powers. If we categorize investment in the industry percentage wise we would probably arrive at a result based on the following lines:

- National Newspapers both in English and Indian Languages weeklies and periodicals

- Central and State Government establishments

- Leading commercial and book printers

- Medium and small job printers

-Un Quote

Stating that no industry has undergone more radical changes in approach and technology during the last two decades as the Printing Industry , the Committee took the following factors for their study which according to them were key to bridge the gaps in technology in the field of Printing .

Quote:-

- Capital deployed in the industry in various categories

- Age of the equipment with reference to useful life span in relation to the normal working life of the equipment concerned

- The capacity of various sectors of the industry for modernization and reinvestment

- Inhibiting factors both in the field of technology and raw material availability

The Committee felt that ‘the changes if any had to be in consonance with viability and availability of manufacturing skills in the country so that maximum number of printers will be benefited. Such an approach will also save foreign exchange by import substitution and export earnings by indigenous technology’. Though opportunities and avenues were available to carry forward reforms in the Printing Industry , they were not utilized as expected says the report. The Committee observed that ‘though awareness on the developments which were taking place were there, entrepreneurs given sufficient facilities to go abroad and the capital available, there was reluctance by entrepreneurs to find out avenues of development to either partly or wholly manufacture them within the country and instead they preferred to import the machineries and equipments’.

The Private entrepreneurs in the Printing Industry alone cannot be solely held responsible for this lackluster attitude, the same tendency was noticed in the Governmental sectors too. However it was noticed that the Newspaper industry which has substantial portion of printing machinery and equipment were progressing much better than the general Printing Industry. This was highlighted in the report in the following manner: ‘On one hand while the Government printers in foreign countries play significant role in research and development and set in place for technological improvement, in India though the Government printing represents one of the biggest sectors in the Printing Industry, very little or no significant role has been played by them in this direction, reason being Government Printing Industry continued to rely on the orthodox machines and methods’.

The report further observed that ‘the Printing Industry has not been given status of the industry like tool industry, the electronic industry, chemical industry, textile industry etc, and probably this could be the reason for the present state of affairs’ and therefore in order to ‘effectively meet the demand in quality and quantity, the industry will have to orient itself towards development based on Science and applied Technology. It will therefore need new materials and machineries and the entire range of scientific know how to modernize, standardize and replace the traditional ones with modern technology. With the participation of 50,000 or so small printing and allied houses and handful of large firms, Government should try to establish Central Research and Development Organization (CRDO)’.

Production of capital goods and developing and making printing machines and ancillary processes for the Printing Industry require lot of capital. The Printing Industry is one that requires diverse variety of processing equipment and materials and necessary skills for manufacturing them and if such an exercise is to be carried out, large measure of assistance from the Govt will be required. There has been no Government’s initiative for bringing the user industry participation or themselves going in a large way to give the printer the printing machines and materials needed for modernization. Requisite capital for the research and development program could not be generated in the private sector as the private sector consisted of large number of small entrepreneurs who were reluctant to part with a margin of their profit for the said purpose.

Under immediate need for an institute of printing technology and machine design the report mentioned that out of over 25,000 presses in India, 75% had less than 25 working personnel and excepting few presses which had sophisticated equipment as computer aided type setters, photo type setters, electronic engraving, high-speed four colour web offset rotaries etc, a great majority of the printers were thriving on outdated technology and over worked machines. It was seen that as against per capita consumption of 260 Kgs of Paper in USA, India’s per capita consumption of Paper was hardly 2 Kgs which reflected the growth rate of Indian print industry in comparison with the International print industry. The report said that in the year 1972/73 the turnover in the Printing Industry was estimated to be 400 crores with an annual growth rate of 6% excluding News Papers. The value of imported machineries and equipments imported into India for the Printing Industry is between Rs 12 to Rs 15 crores per annum out of which a major portion came from the East European countries.

The report mentions that in the area of designing and manufacturing quality printing machines, only one public sector (HMT) unit under Govt control went in for collaboration with a Italian firm for manufacturing some printing machines while half a dozen or so firms in the private sectors have set up small and medium size plants for manufacturing Printing machines, Paper cutting machines, punching and miscellaneous machines ancillary to printing. Nothing worthy to mention on designing or manufacturing other Printing machines or ancillary equipments were seen either in the Public sector or in the Private sectors. Therefore there was tremendous scope to research and development in printing to bridge the gap between manufacturing machineries and equipments to reduce dependency on the imports by producing them indigenously on par with imported machinery standards. Besides designing and manufacturing machineries and equipments, development of ancillary processes and processing materials required for them are also to receive greater priority for development indigenously.

(Note: However the scenario is totally different now. While the Printing machine manufacturing activities of HMT have since shrunk for varieties of reasons, lots of manufacturing firms for the Printing machines, equipments and apparatus have emerged all over India, especially places like Punjab, Haryana, Noida, Maharashtra, Sivakasi, Coimbatore, Ballabgarh, Faridabad, Pune etc. They manufacture Converting machines, Hot Foil Label Stamping Die Cutting, Web and Sheet fed Offset Printing machines, Rotogravure, Label printing, Flexo etc, either with independently designed or in collaboration with foreign manufacturers. However though most of those indigenously developed machineries and equipments could not be compared to latest generation technology, in the field of manufacturing essential spare parts-both mechanical and electrical to electronics- and PCBs for the latest generation technological machineries and equipments, their standards are as high as International products – author)

The report pointed out that even for types, design matrix and their manufacture for Indian languages India entirely depend on imports. Nothing worthy of mention has been attempted in respect of manufacturing various ancillary equipment and processing material as required by the Printing Industry. The attempts made so far have only touched the fringe of the problem. The gap to be bridged is still wide and there is tremendous scope for research and development, for designing and building of printing machinery of all kinds and for the manufacture of ancillary equipments, measuring devices, processing materials and chemicals. The industry practically imports everything required for printing.

(Note: It is sad state of affair to see that some countries in the Asian region flood the market with highly cheaper products manufactured from their countries due to cheaper labour force available there. Also substantial benefit given in the form of tax waivers on exported products enables the manufacturers to reduce the cost of their products. This thus affects the indigenous production and dash the hope of considerably saving foreign exchange. This new factor needs to be addressed by the Indian Govt to encourage indigenization of spares and materials at least in the Printing organizations controlled by the Govt – author)

In order to assess the extent to which the gap in the technology in Printing Industry has to be covered, and how to reduce dependency on the imports the Committee examined the report of a panel set up by the Govt of India, Ministry of Steel and Heavy Industries to survey printing machineries requirement in India, the annual demand for the printing and allied machineries in the fifth plan period, approved and registered capacity for manufacture in India including the letter of Intent issued by the DGS&D and the actual capacity of the organized sector etc. The report mentions that the data collected from above were not however sufficient and did not reflect the true picture. Therefore the Committee also considered the technological requirements that have taken place during the past 20 years in the Printing Industry . Bridging the gap in the technology does not stop with building machineries and equipments alone. It also needed development of ancillary equipments and materials in order to effectively utilize the machineries.

The report mentions that some of the important machineries and equipments imported were:

- Photo Typesetters- both Hot and Cold composing

- Sheet fed and Web fed Offset and Gravure Presses

- Letterpress News Paper Rotaries

- Special purpose machineries of many types

- Sophisticated Process Cameras

- Precision Enlargers

- Plate Making Equipments

- Photo polymer Plate making and Powderless etching machines

- Electronic Engraving machines

The Committee felt that in order to bridge the wide open gap in technology certain equipments and processes listed below may have to be quickly surveyed and developed in India.

Letter Assembly:

Hot metal composing and casting machine

Hot metal single type composing and casting machine and ancillaries

Matrices for above, in English and Indian languages

Suitable Photo typesetting machines for English and Indian languages

Suitable keyboard for above

Type design for Indian languages

Display for Photo type setter

Image Assembly:

- Process Camera

- Precision Process Enlargers

- Colour Scanners

- Hydraulic Matrix Mounting machine

- Powderless etching machine

- Electronic Engraving machine

- Step and Repeat machine

- Letterpress (Sheet fed)

- Precision Proof press

- Platens

- Cylinder Processes

- Offset and Letterpress (Sheet feed)

- Proof Press

- Single Colour presses

- Multi Colour presses

- Web fed Machines (for News Paper, Book work, Stationery and others)

- Letterpress

- Offset/Letter set

- Flexography

- Photogravure

- Folding machines

- Gathering machines

- Case making machines

- Wire stitching machines

- Perfect Binding machines

- Cutting and creasing machines

- Envelop making machines

- Lamination machines

- Rotary Board cutting and creasing machines

- Gold Blocking machines

- Tag making machines

- Ticket printing machines

- Guillotine and three side trimmers

- Feeders

- Anti set off sprays

- Rollers

- Numbering boxes

- Blanket and Roller coverings

- Guillotine knives

- Forme Trolleys

- Mounting bases

- Block Gauges

- Locking up devices

- Plate registration devices

- Measuring and testing devices

- Electronic paper counting machines

- Light sources for exposure (Pulsed Xenon lamps)

- Anodized Plated

- Polymetal plates

- Photo polymer plates

- Presensitized plates

- Paper plates

- Photographic films and materials of various sizes

- Materials like Inks, varnishes, bronze powders, adhesive resins etc

- Electrostatic Printing (Xerox)

- Photocopying devices

- Electronic Typewriters and cold composing

- study the state of affairs of the industry

- survey the industry requirements

- investigate the problems in technical areas

- identify areas of research and development needed

- provide standardization procedures by coordinating with the Indian and International bodies

- interact effectively with different printing institutions in India and abroad to disseminate information

- provide industrial consultancy service in design and manufacture of machineries and equipments

- provide training and testing facilities

As a research centre it has been in position to develop prototypes for various processes, provide meaningful information on materials used, and monitor new developments in these areas and pioneer basic studies for their improvement in keeping with the phase of technological change. The report further highlighted PIRA’s extensive work on plates for plate making, alternative light sources and their effect on plate coatings, ink behaviour and such phenomena as ink fading, tack, and study on photo polymer plates from both economical and technical point of view.

In the area of new technology PIRA has done original work in finding ways of applying new technology, sometimes from quite different industries to the problems of paper making, printing and packaging. It has also attempted studies on aspects of materials and machines with relevance to industrial needs. Here again it has looked at the performance of paper in relation to high production costs and wastage, contamination of fibers on litho blankets and on paper stretch on printing machines.

As a consultant to industry, PIRA has closely allied itself with the concern of the industries on profitability. PIRA has been able to provide information to all concerned from its information bank. Besides scanning world publications and providing latest trends in world’s science, technology, trade and patent literature, it has also been able to have direct contacts with Research bodies and Professional Institutions. PIRA operates with three different divisional committee- one for Paper and board, second for Printing, and third for Packaging. Each division undertakes research projects and is responsible for the information and technical inquiries and information and training functions.

Taking cue from PIRA, the report proposed setting up an Institute on similar lines. As per the report, the Institute would be known as Graphic Arts Research, Machinery Development and Training Institute (GARMTI) and will be administered by a Governing council and ensure Industry participation by accepting sponsored projects for research and development. GARMTI will have a fleet of personnel in administration, engineering and service departments. As stated earlier, the Committee observed that the turnover in the Printing Industry in 1972/73 has been estimated to be 400 crores with an annual growth rate of 6% excluding News Papers and expected to grow over to 580 crores in the year 1980 after the establishment of GARMTI. The export potential of print material valued as 1.75 crores in 1972/73 was also expected to grow over by ten times with improved machinery, modern technology and adequate number of trained personnel. With the establishment of GARMTI the imports by the Print industry would also simultaneously come down to save the foreign exchange while the export of print material will drastically go up.

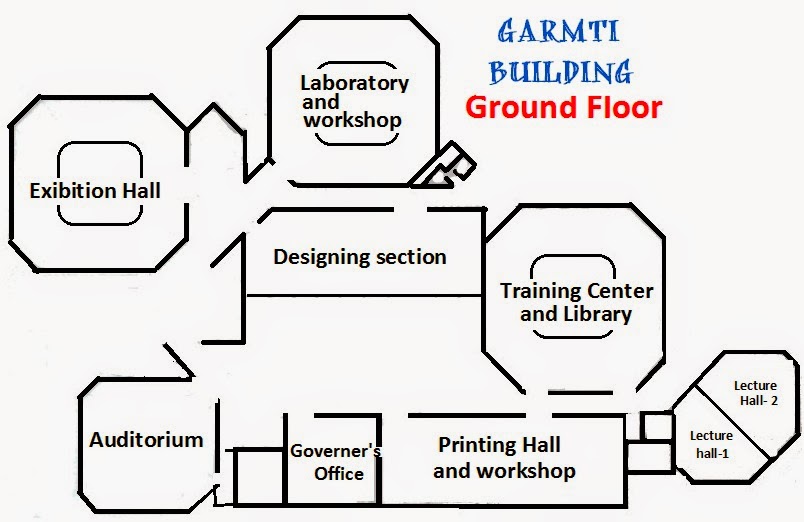

The report suggested few ideal locations of the institute as Hyderabad, Pune, Bangalore, Chennai or in Delhi in an area of approximately four acres of land. Since the building construction will take few years /months it was suggested to set up a temporary Office in a rental building operated with few staff.

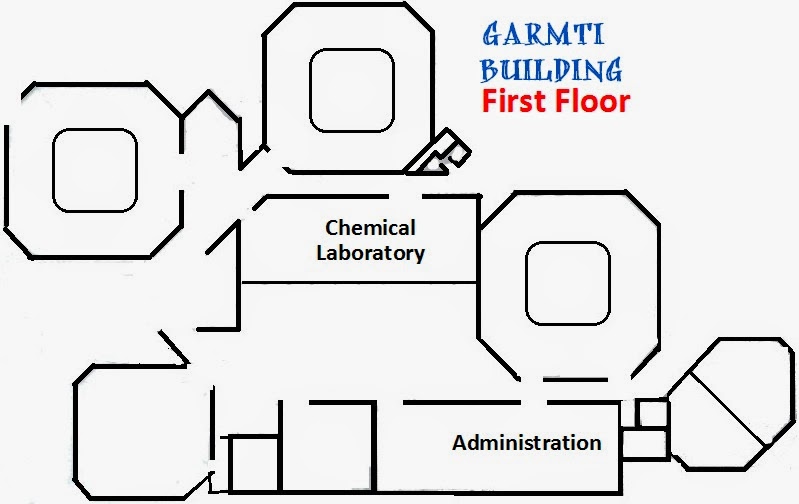

The structure of GARMTI would be:

Designing and Engineering for preparation of engineering drawings, technical documentation which may be necessary for the fabrication of machineries and equipments, development of prototype assemblies etc, evaluation of machineries and equipments and scrutinizing import of technology.

The Committee expected the Institute to develop design competence, design of machines, design of sub assemblies, materials and processes either directly or by way of collaboration with international companies. The one way of developing design competence is to apply massive training in different facets of design for long periods of say few years to promising technologists, scientists, mechanical, electrical and electronic engineering graduates. For example such a scheme in Machine Tool design has been developed in collaboration with Czechoslovakia.

Research and development in Paper, board, inks, printing plates, coating solutions, rubber rollers covering etc. Developing measuring devices, quality control equipment, consultancy service, problem study on the above etc.

Since sufficient facilities and training are not available in India in respect of design competence, this Institute will work out suitable collaboration pact on Government to Government basis with the firms willing to share the technology for designing the machineries and equipments required indigenously.

Since no survey has been carried out regarding the availability of materials and processes, the Institute will survey and develop the available materials and processes by coordinating its activities in its own laboratories or through other research organizations. If the traditional small scale industries are to be modernized, research and development is necessary and this institute will fill up the said vacuum. The Institute can carry out the research in developing machineries, auxiliary equipments, raw materials and consumables.

Dissemination of information to industry, documentation of all facts, liaisoning with industry, research institutions, training institutions etc. Hold seminars, and conferences, prepare training material, prepare and publish abstracts from technical literature, research papers and reports.

The Institute will have a well quipped Library that will have literature of entire range of machineries and equipments, processes and raw materials, consumables apparatuses etc which will be updated as much as possible so that from a single point of source the required information can be culled. This Institute will interact with Research and Development Organizations like PIRA formerly known as PATRA (Printing and Allied Trade Research Association), GATF (Graphic Arts Technical Foundation), IGT (International Graphic Techniques) of Holland and FOGRA of Germany (Fogra Graphic Technology Research Association) etc. Besides sources from international arena, this institute will also collect data from the Indigenous manufacturers and keep them in the Library for reference purposes. In this manner the Institute will be able to provide whatever information the Printing Industry may require.

At this juncture no consultancy service is available to give the Industry suitable advice on technical aspects including on new projects or introduction of new processes. Therefore this Institute will offer consultancy service on specified fee.

Training:- Training programs are scare as far as the Printing Industry is concerned. The employees are normally trained by the staff from the employer itself, but not in the proper manner required. The situation is still worse where some of the Industrial units have apprenticeship schemes or when the freshly recruits from the Printing courses are recruited. This institute will also act as training centre on the basics as required by the specified industry especially when new technology is introduced .

Personnel required for the Administration and Finance departments, for the Institute for carrying out the above activities.

What the proposed Institute will do, the methodology and activities have been classified in the report in the following manner:-

Quote:

1. To engage in practice oriented research, design and development for generation of information leading to commercial use of graphic arts technology, machinery, materials and processes.

2. To study and review the state of the industry in India, survey the available facilities, materials and processes and identify specific areas in which research and development work would be profitable.

3. To provide for standardization, evaluation and certification of equipment, machinery, processes, materials etc.

4. To coordinate with Indian and International standardization bodies in formulation of standards.

5. To investigate problems posed by industries and provide solutions

6. To provide feedback to manufacturers and users of equipment, machinery, processes, materials etc.

7. To stimulate and encourage the application of improved graphic arts techniques consistent with the changing pattern of technology

8. To interact effectively with different institutions in India and abroad whenever necessary for the benefit of the country and industry

9. To provide industrial consultancy service in design, manufacture or choice of equipment, machinery, materials, processes and in quality control to the graphic arts industry

10. To provide training and testing facilities for all levels of personnel engaged in graphic arts in order to increase professionalism in printing and allied trades.

11.To render assistance to the technical teaching institutions and to participate in/organize seminars, conferences and refresher courses on graphic arts technology and machinery.

12. To prepare training material

13.To disseminate information to users by effective methods and to engage in extension services

14.To act as a clearing house for import of technology, specialized equipments and materials with a view to meet the needs of the industry and to rationalize choices to achieve consequential advantages in maintenance, inventory control, operations and profitability.

Un Quote

Recent Comments