Guide to Printing Students – 26

-Few objective Questions and answers-

Written by : N.R. Jayaraman

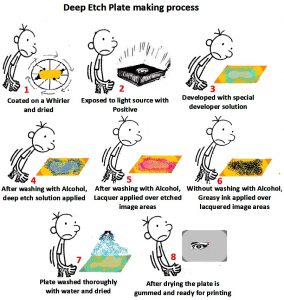

111) What is Deep Etched plate ? How is it prepared ?

Deep etched plate is another type of plate making process for Offset printing. The plate required for printing is the same set of metal plates –either Aluminum or Zinc. Instead of negative, a positive film is used for making the plates. In this plate making process the image areas are etched to give strength to the printing areas. The insignificant depth of pit created is covered with greasy ink and lacquer which rests in the etched areas leveling the surface with that of the non image areas. The etched areas are chemically coppered, lacquered and finally inked to make those areas remain stronger on the plate, be more ink receptive and to be on level with the surface of the plate. The image is held by the insignificant recess though the image will not be in relief like letterpress blocks. This is one of the major reason why the Deep etch plate gives more no of print runs than the plates made by other processes.

Another major difference between Surface plates and the Deep Etched plates is the use of Gum Arabic or PVA (Poly Vinyl Alcohol) in place of Albumen or Casein as used in the sensitized coating solution meant for Surface plates. The steps in the processing are almost similar except minor additions in some steps. How is the plate made?

- The plate for Deep Etch plate making are to be necessarily counter etched with a weak acid bath consisting of Hydrochloric acid with water for Zinc plates and Phosphoric acid with water for Aluminum plates. The counter etched plate will be taken up for coating.

- Once the plate is coated with sensitizer solution consisting of Gum Arabic solution with Ammonium Bichromate and Ammonium Hydroxide or PVA (in place of Gum Arabic) in certain ratio, the coated and dried plate will be exposed to a positive and not negative.

- The exposed plate will be treated with a Developer solution which may consist of Calcium Chloride plus Lactic acid combination in certain ratio. The developer is poured over the exposed plate and rubbed in circular motion covering the entire image areas with a developing pad made of cotton wool. Once the image begins to show, the development is stopped and the excess developer squeezed off from the plate to stop the action of the developer and again fresh developer is poured and image further cleared. In this manner the development continues by two to three times to create clear image on the plate.

- Then comes the process of deep etch solution prepared with certain chemicals such as Calcium Chloride, Zinc Chloride, Ion Perchlorate, Hydrochloric acid and Cupric Chloride etc. Some plate makers use Ferric Chloride too in some formulae. No of commercial Deep etch coatings including developer and etches are also made available in the market.

- After sufficient depth is derived on the image areas which can be assessed by experience, the deep etch solution will have to be thoroughly washed with water free Isopropyl Alcohol and dried to ensure that the etched image areas accept the copper, lacquer and the greasy ink.

- Copperising the image areas is optional action. The Copperising solution consists of chemicals such as Isopropyl Alcohol, Cuprous Chloride and Hydrochloric acid in certain ratio. The Copperising solution is poured on the image areas and rubbed with a cotton wade till the image areas appear dark pink in color. The plate surface will again be thoroughly washed with Isopropyl Alcohol to clear the Copperising solution. Every time fresh step in the process commences, the treated plate surface will have to be cleaned with Isopropyl Alcohol and dried to nullify the action of the chemical solution used.

- Next step is to apply the non-blinding lacquer which gives the image areas strong ink receptive tendency and to act as the bonding agent between the deep etch areas copperised and the ink applied after lacquering.

- Note an important deviation in procedure here. After sufficient lacquering exercise is done, without washing the surface with Isopropyl Alcohol, the greasy ink will be applied over the image areas lacquered to have tight hold on those areas for printing.

- Finally the plate will be thoroughly washed with warm water and rubbed with a smooth brush to remove the layer of hardened sensitizer coating still staying over the non-image areas. If sometimes, when the hardened coating is still feebly visible, then very mild Phosphoric acid mixed gum solution is applied to remove the hardened stencil and then finally washed again with water to make the surface clean. Once the hardened non image area coating is cleared by scrubbing with a brush and plenty of warm water, the plate is gummed and kept ready for printing.

Recent Comments