Guide to Printing Students – 35

-Few objective Questions and answers-

Written by : N.R. Jayaraman

147) What is Digital printing process?

This is a process in which the image is created on the computer in the form of digital signals and transmitted directly to the output device i.e. the printer. Digital printing is a printing technique using digital or electronic files from a personal computer or other digital storage device as a source. No pre-press operation including making of negatives from the composed matter, assembling of layout etc, or making of printing plates are required. The prints are taken from the layout created in the computer consisting of both text matter and the photographs or illustrations of many types including the colored ones on the computer itself and thereafter printing the same on to the desired substance with liquid ink-jet, wet/dry toner systems, solid ink-jet, thermal-transfer etc. Due to lower production costs, and short period of time involved in Digital Printing system it has replaced Offset printing in the world of print market.

148) What are the advantages of Digital printing?

- It is possible to print variable data obtained from the database or external files.

- The position and colours of the texts and graphics can be changed on each sheet without stopping or slowing down the press. For example, personalized letter or advertised material can be printed with a different name and address on each one of them.

- It is flexible process which need no pre-press operations.

- Even bigger sized posters of only few copies can be printed in the shortest time on some of the Digital printers which can take paper from the reel to print the copies.

- The Digital printing is boon to the packaging and pharmaceutical industry where the variable data print labels and cartons are needed for packing the material.

- The printed brochures, advertising print material, fliers, posters, banners etc could be easily reproduced by the Digital printing machines at a faster and economical rate compared to conventional processes of printing.

- Besides speedier and faster delivery of the print material, intricate designs which the conventional print processes could not offer in shortest period of time can be accomplished by the Digital Printing process.

- The Digital printing technology offered varying surface finishes of the same designs, high depth three-dimensional graphic designs etc.

- The Digital printer equipment save space.

- It is best suited for printing small quantities of jobs, instantly needed prints and on demand printing which are required in the shortest possible time.

Paper wastage is avoided.

Matching true color is easily done on the computer before printing on the substrate.

149) What is ‘on demand printing’?

The ‘on demand printing’ is referred to digital printing which makes it possible to print brochures, mails, labels, fliers etc, on need based basis at short notice or across the table deliverable before the full purview of the customer and thus meet the requirements of professionals and other industries who needed prints in few hours. This is especially best suited for printing of thesis, research papers and project reports etc which are submitted confidentially in shortest period of time. Few amongst the needs were even one or two prints only and thus the coinage of ‘on demand printing’ given.

150) What is Dye Sublimation ?

In Dye sublimation is a process in which the image is first printed onto a special coated paper and then using some form of heat, the images are transferred onto the substance required to be printed including that of fabric. Most of the dye sublimation inks are water based inks and the images are initially printed on specially coated heat-resistant transfer paper. The printed image on the transfer paper is then transferred onto the substance required to be printed using heat press process or some other suitable heat generating mechanism working at high temperature which first loosen the hold of the image on the coated paper, however without damaging its original form to stick on to the surface required to be printed. With the Dye sublimation process of printing any number of colors of any image can be printed on any substance.

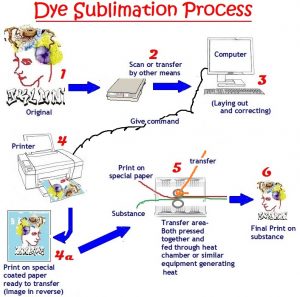

151) Explain the process of Dye sublimation?

The Dye-sublimation process which belong to the family of Digital print process is carried out with a special computer printer meant for this process which along with heat transfer Ink transfer the printed dye ink onto the materials such as a plastic, card, paper, or fabric.

Before the print image gets transferred on to the substrate, the printed dye turns into gas status instead of going into liquid status and get attached on to the surface of the substrate which is subsequently made to firmly remain adhered to the surface with heat. One coated paper can transfer only one print image from its base unlike taking many prints from a single block or plate in the conventional print process. This process involve the following steps which is also shown in the illustration at the end:-

- Prepare the original.

- Feed it into the computer by scanner or other manner of uploading.

- Make necessary corrections and bring it to the size required to be printed.

- Send the image from the computer into the Sublimation printer to transfer the image on to the special coated paper meant for sublimation process.

- Use the specially coated paper for transferring the printed image on to the required substance by ‘contact and press against each other’ to transfer the image from the paper on to the surface of the substance through a suitable heating mechanism.

While the Dye sublimation printer do not use black colour it use a special over coating as fourth print. Therefore in the process of printing by dye-sublimation, CMYO (Cyan, Magenta, Yellow and Over Coating) colour system is used, though some printers do use black ink additionally.

Though it is also a family in the Digital printing, unlike direct Digital printing which is a one step process of printing i.e from the printers on to the substance, the Dye sublimation process acts as two steps process i.e the image gets first digitally printed on the special coated paper with the high ink absorption capabilities and then by heat transfer process transfer the images on to the substance.

Recent Comments