Random Thoughts – 3

In order to reduce the waste percentage of the printed stocks it is necessary that simplified system is worked out to enable better feed backs between the presses and the paper mill to sort out the technical problems arising out of Paper during printing.

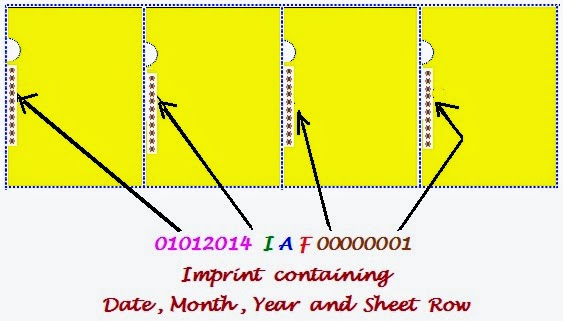

2. For example the imprint can begin with date something like 01.01.2014 etc which should be changed by the supervisor at the beginning of each day from a central command or it can be fitted with auto change date system.

3. Date to be followed by the shift prefix say “I” for the first shift, “II ” for the second shift and “III” for the third shift and so on.

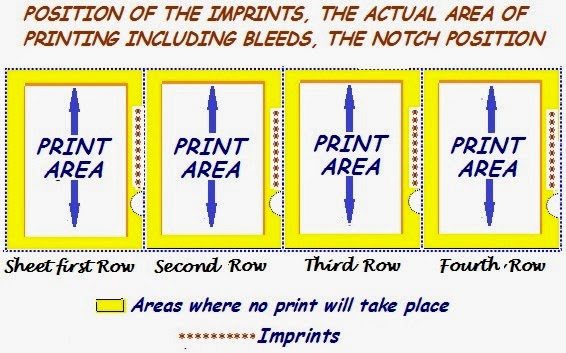

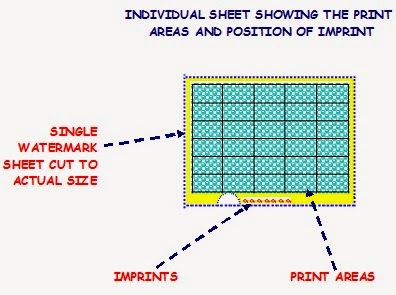

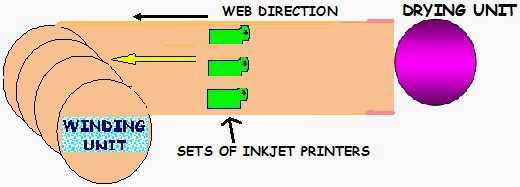

4. If the sheet row in the web is first the code could be F, and for the second it could be S and so on. For the machine detail indicate A, B and so on (See the illustration to understand the sheet row).

5. The serial no of sheets can then begin say starting from 00000001 for the first row. Again 00000001 for second row also as the sheet position will come as prefix or anything like it.

6. Next day again with the change in the date the sheet will have the first serial no for the day like 00000001 for the first row. Again same no 00000001 for second row .

7. I guess that the consumption of ink will be very minimal. In fact it will not be even 1/1000th of the cost of paper per MT.

8. In fact if the auto dates and time changer is provided with the Ink Jet printer, it will automatically record the time of manufacture. The auto time changer can be adjusted in such a manner that the time of manufacture will change every one hour in the following manner:

12-05-2014 : 10.30

12-05-2014 : 11.30

12-05-2014 : 12.30

12-05-2014 : 13.30

and so on

9. For example the paper lots produced on 1st January 2014 in the first shifts will have the following imprints.

01012014 I A F 00000001

01012014 I B S 00000001

01012014 I C T 00000001

a) ‘01012014’ represents the date, month and year i.e 01-01-2014

b) ‘I’ represents the shift i.e first shift

c) ‘A’ or ‘B’ or ‘C’ represents the machine No

d) ‘F’ or ‘S’ or ‘T’ represents the first, second or third rows of paper in the web

e) 00000001 is the serial no which will change as 00000002, 00000003 and so on till the end of the shift .

10. For the second day the imprints will appear as 02012014 I A F 00000001

02012014 I B S 00000001

02012014 I C T 00000001 and so on as above

11. The fitment will also be simple and not complicated as the jets are to be connected to a rod over web in between the drying unit and the winding unit.

2. The ream label contains the name of the operator, the date of printing, the shift, personnel who handled it etc. This can be discarded by pasting only the firm’s label .

3. In the event the presses face problem in a particular lot, they can easily identify the correct sheet details and communicate to the manufacturer for taking corrective action.

4. Once the details are received from the customer the manufacturer can immediately identify the problems or identify the erring crew for the lapses without wasting time.

5. It will be easier to track the faults in minutes with the details received. The complainant will also find it easier to send the correct information pertaining to the defective lots.

Recent Comments