Alphabet – P

1. Paper Plate : A special type of paper based printing plate with a laminated back, meant for use on small Offset Printing machines. Once very popular for small Offset machines like Romayor, Rota print, Swift, and Adast Offset machines, their usage is gradually diminishing due to the electronic and digital printing. The Paper plates are also called Rotamasta Paper Plates. Even though the users are not many like when it was when invented, still in some of the printers continue to use paper plates and the plates are supplied both in sheet form and in rolls by firms like Elefax / Itek / AB Dick / Ricoh / Fuji /Mitsubishi / Eskofot / Gestetner etc in some countries.

The Paper plates are similar to the thin anodized aluminum plates and are durable with plastic base having coating of some material similar to the properties of Zinc or Aluminum plates. Being flexible material like thick paper, the text to be printed is photo copied directly on to the plate or typed through a typewriter machine. Even direct writing on the plate with special oil based ink was possible to draw the sketches or drawings without pressing the surface hard. Once the image are formed as stated above, the plates will have to be treated with a special solution supplied along with the paper plates that convert the surface properties of the plates to that of the properties of an Offset printing plate – water resistant on image areas, and ink resistant on non image areas.

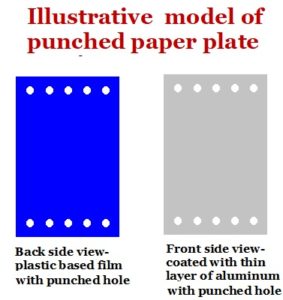

Similar to Offset printing plates, the paper plates too accept the printing ink on image areas and transfer them on to the blanket, which in turn print them on paper. The Paper plates were meant for short run copies on small offset presses and are made available to the maximum size of A3 . The paper plates are not clamped on the plate clamping bar on the Plate cylinder and tightened because they can either break or stretch with such an exercise. The Paper plates can not be used on all the small Offset machines. Therefore only certain machines are made available with punch hole clamps to hold the paper masters. The small Offset Machines supplied for use of Paper plates have special plate clamping attachment with pins that hold the paper and in order to facilitate the use of even thin aluminum offset plates on the machines, the offset aluminium plate suppliers offer plates with punched holes to fit on those machines.

The paper plates oblong in size have punched holes on both top and bottom sides to directly push them in to the pin bars of the plate cylinders which will firmly hold them in permanent position. The disadvantage in using paper plates are that the images can not be stretched by few microns like how the Zinc or Aluminum plates fitted in the plate cylinder clamps are tightened to compensate the previous colour image stretch. Similarly it is also not possible to adjust the plates to straighten the printed images if they show slight deviation between two sides for the same reason.

2. Parent Sheet : Any blank sheet meant for printing larger than A3 size are in printers term known as Parent sheets. Since most of the commercial presses have bigger machines that can print bigger size sheets, the smaller size jobs like running letterheads, invoices, bill books etc of bigger organizations on long term contract, booklets, and pamphlets with huge copies are printed on bigger size sheets with several ups and after completion of printing, wherever required are folded and trimmed to the required size of job. Such an exercise is found economical and therefore the bigger size sheets of the same paper which are used for printing of several ups of smaller size job is called Parent sheets. Also because the bigger size of papers received from the Paper mills are directly used without first trimming them to other smaller size, they are called Parent sheets.

3. Page : Each side of the printed material, whether in book format, circular, pamphlet, leaflet, posters, info letters or for that matter any other printed sheet is technically called a page.

4. Page Count : Total no of pages in any of the printed material is called page count.

5. Pagination: Each printed book will have several pages. Each pages are numbered to indicate the text position. The process of dividing or arranging or breaking the entire print matter along with graphics into several pages, each containing fixed area of text matter as per the layout and then adding page number is called Pagination in printers term.

In respect of Web pages, the word Pagination refers to organizing certain amount of data in one page so as to facilitate the readers comfortably see and read the contents without strain to the eyes. Pagination i.e breaking the matter into several easily readable format alone does not complete the word Pagination. It also includes the process of numbering. Unless the pages are serially numbered, it will not be possible for the readers to keep track of where they have left the reading. Similarly unless the pages are numbered it will not be possible for the binders to collate (collect the sections of the book) and keep all the pages in correct sequence or order before binding. Therefore each page of the books are also numbered when the pages are printed. When the print matter is composed in the computers the pagination and numbering of each pages are done automatically by activating the page break and numbering buttons .

6. Pantone Matching System: Basically all the colors emanate only from four basic Process colors such as Cyan, Magenta, Yellow and Black (CYMK) or from display colors Red, Green and Blue (RGB). The combination of these color produces multiples shades. Supposing desires to print a book containing several designs with certain special colors and he wants a quote for huge no of copies, how can that be made possible unless the availability of special colors are known when the color effects are shown in computer? Unless there is color consistency or clarity on the colour to be reproduced between the designer, printer and the ink maker, the client requirement in respect of specific color can not be met with.

- How to convert the color as projected in the monitors of the design, in printable format to quote? Is it possible to produce the same color in print as projected in the monitors ? If this is to be done the first task is to convert the RGB into suitable shades of CMYK to print on a four or three color presses. Once it is made possible, then it will be possible to bring uniformity with all the printers whoever they are, to print the same shades once or any no of times even with intervals. How to do it?

- The real problem is how can the color once printed and approved or accepted by the client can be reprinted in another place with the same shade? The biggest challenge to the the printer is how the identical shade or color desired and produced by an agency in one place, when required to be reprinted in another place could be closely matched?

- An associated problem that may arise is the paper on which the correct shade is to be printed. Supposing a particular color has been printed for a client in coated paper, but the client require the same to be reprinted in uncoated paper without compromising the shade is it possible to ditto match the same shade?

- To further clarify this problem, let me give this example. Supposing a particular shade of Red has been first printed in one press and the client desire the reprint after a gap of two years with the same shade both to be printed on coated and uncoated paper, how will the printer order ink for the particular shade? The one way is that the printer mix ink in several shades to compare and conclude the correct shade which may match or may not in both the stocks of paper- Coated as well as uncoated. This issue apart, the process of mixing the inks to bring to correct shade is a time consuming as well as waste of material. There may be several Red shades much closer to the Red already printed, available in the market. Each Ink maker may offer their own version, which may or may not match 100% with what has been once produced. How to overcome such issues?

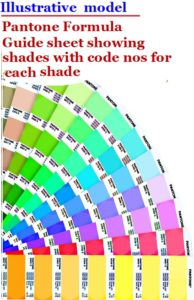

In order to alleviate such problems and to bring consistency and uniformity of shade for the print material, a unique system called Pantone color Matching System (PMS) was introduced and subsequently accepted internationally as the correct system to specify the color shade and to keep colours consistency by different printers or ink makers across all continents. PMS was developed in the year 1963. Pantone Inc is a corporation headquartered in US which introduced he Pantone Matching System (PMS).

What is PMS? It is a primary formula guide for the ink mixing system to bring uniformity in the shades. This huge development allowed the designers and printers to communicate color shades by simply referencing a Pantone number. Early versions of the Pantone formula guide had different colors, on coated and uncoated stocks.

The standardized Pantone Color Matching System expressed the shades of ink with the specific code no of PMS, that helped different manufacturers in different locations to ensure supply of same shades of ink without direct contact with one another as each colour shade of PMS contained ink mixing formula too using 17 pigments that included White and Black Pigments.

The PMS chart contains nearly 1,341 Pantone solid colors, printed on coated, uncoated, and matte paper base. They have given special code for the papers too to identify the shade required. Supposing you need Red for shiny paper order Red 908 C in which the letter C refers to coated stock. Each page contains seven colours each shade obtainable with ink mixing formulas. These pages also specifies how the shades can be obtained by RGB on computers or color monitors and by CMYK in print.

This chart help the designer specify the color in PMS code , the printer is able to order the same shade ink and the client gets exactly what they want. This end to end color control explains why Pantone has become the worldwide standard for color since it’s introduction. In order to help identify the same shade which may appear differently on different stocks of paper Pantone shows how the same shade of colors look on coated, uncoated, and matte paper.

To understand more about Pantone go to the following site:

http://www.pantone.com/pages/pantone/pantone.aspx?pg=19970&ca=1

Recent Comments