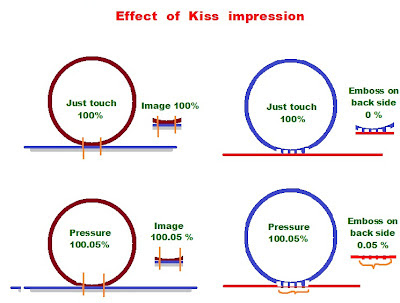

1. Kiss Impression : A delicate printed impression, but print sufficient enough to be seen. This term is attributed more while printing thin paper in which, the impression from the back side should not be visible on the back side, which otherwise will mar the appearance of the print material.

Also in normal paper if a heavy impression is given, the image will slightly appear smudged at the edges. Therefore it is essential that the lightest possible impression that will transfer ink to a substrate should be given. This is called the kiss impression. In Offset printing, the standard procedure for quality printing has been to set gap between the blanket and impression cylinder in such a manner that the blanket transfer the image just by touching the top layer of the paper to the extent that the print image is clearly visible on the paper. This is also the case in Letterpress process, where the relief on the blocks, plates or fonts should just touch the paper and not press them too hard to show some amount of embossed image on the backside, especially while printing sensitive carbon less paper stocks.

By saying Kiss Impression it is to be understood that the image transfer should be made with ideal impression, which should neither be too heavy, nor inadequate print impression, and finally be not to leave any impression at all. A harder impression might produce smudged ink around the edges of the printed areas. A lighter pressure would not adequately transfer the image and therefore a delicate impression between the two has to be given so as to print the image by transferring ink to the paper.

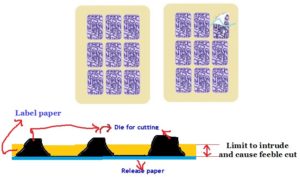

2. Kiss Cut: Usually referring to trimming the paper or printed substance to size or trim to shape the self-adhesive labels. The release liner backing paper will be the carrier of the self adhesive labels and till the labels are peeled off from the release liner backing paper, they will not loose their adhesiveness. The adhesive labels attached to stuck on the release liner backing paper will be either printed or blank non printed labels cut to different shapes or sizes to meet the actual need.

Since the adhesive paper can not be removed from the release liner backing paper and then cut to size or printed with some text, the pr- printing or pre-cut to specific shape should be done only when they still remain on release liner backing paper to enable the self-adhesive label to be peeled off in required shape or size. The Pre cut shape/ size is effected with specially prepared cutting dies in such a manner that the adhesive label alone is cut leaving the release liner backing paper unaffected. This is called the Kiss cut.

3. Key line: The thin lines that are drawn in an artwork or laid out design to indicate the correct size, shape for placement of deign elements including images and text matter. In simple word it is a guide plate for the layout artists for final positioning of the texts and images in correct position. They are thin line in blue indicating positions as stated.

4. Kraft Paper : A tough and strong light brownish paper used for packing purposes. They are also used as wrapping paper, and to make carry bags, sack bags, and large envelopes. This paper is made of both bleached or unbleached long-fiber in pulp. They are produced with smooth base on one side, while the other side will be multiple ribbing for handling without slipping. Since they are made of wood pulp, they come in different brownish shade only. Of late the Kraft papers are also supplied as laminated or varnish coated on one side to add strength to the paper.

5. Kaolin : A white colored mineral substance also called clay is used as an additive and filler and added along with the pulp during manufacturing of the paper.

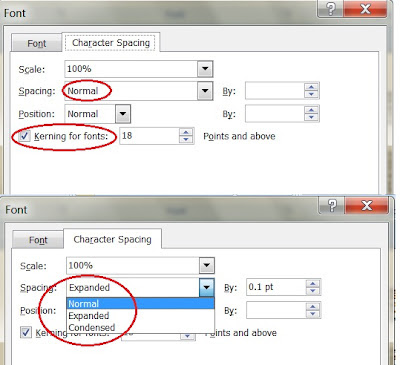

6. Kerning : The narrowing of space between two characters so that they remain closer and take less space on the page. Some times closing the space also makes their appearance better. However note that the kerning is not possible on the manually composed typographic metal fonts or photo mechanical processes like Lino and Mono Types, and will be possible only on image setters and computer aided type setting processes. By kerning, the space between characters can be either increased or decreased.

7. Key Plate : The black printing plate that is used as a guide for the other plates in the color printing process as it usually has the most detail of the print material. All other plates are aligned to this plate.

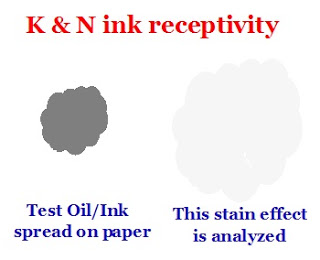

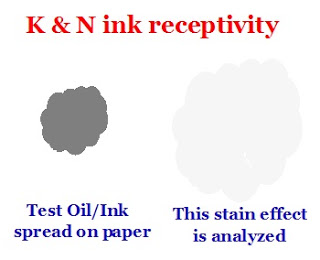

8. K & N ink receptivity: This is related to the testing of the paper meant for printing. The K & N factor indicates the oil absorbency of the paper or penetration test. By this test, a special white pigment, non drying colored oil or ink called K & N ink is smeared on the surface of the paper and allowed to remain on the surface for a specified time, and under specified conditions. Thereafter the ink is wiped out of the surface of the paper with cellulose wading ( cotton like substance) and the degrees of difference in the color depth of the ink stains as absorbed into the paper is measured by a special instrument.

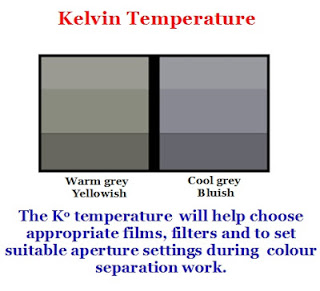

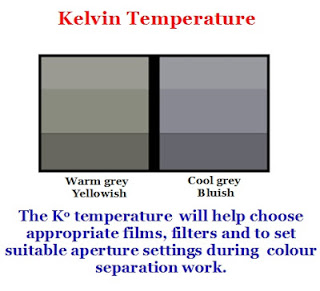

9. Kelvin temperature: The temperature of the light rays are measured for short listing suitable light source and their usage for colour separation. The color temperature of a light source is the temperature of an ideal black that radiates light of comparable hue to that of the light source. Generally the Kelvin temperature is found indicated on the light sources procured. The factor is indicated as Ko.

The bright sunshine measures 5000 Ko which is rated as cool color. Xenon lamps have more than 6500 Kelvin temperature, Arc lamps up to 5000 K, and color photographic Tungsten lamps some thing around 3500 which is thus form the order of preferred lamp sources by the process dept. Low colour temperature implies warmer colors which is towards yellowish shade. Since the UV light is the best required light for photographic purposes, the process department prefers only cooler colour temp lights which is bend towards Bluish shade.

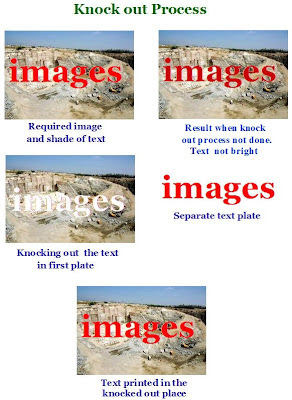

10. Knock out: When some text matter or an art work with lines, large dots, circles, boxes etc is to be over printed over a colored background, the best way to produce the desired color is to first blank ( mask out the exact shape of image to be over printed) the area and then print the rest where such insertions will be needed. Subsequently the desired colour print will be over printed on the blank space. The process is referred to as knocking out process in printing.

…………Additions to alphabet K to be continued under K/2

Recent Comments